Multi-station rotary-table foam connection equipment for mercury thermometers

A mercury thermometer, multi-station technology, applied in thermometers, thermometers based on material expansion/contraction, measuring devices, etc., can solve the problem of not producing valuable economic benefits, and achieve the effect of improving the degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

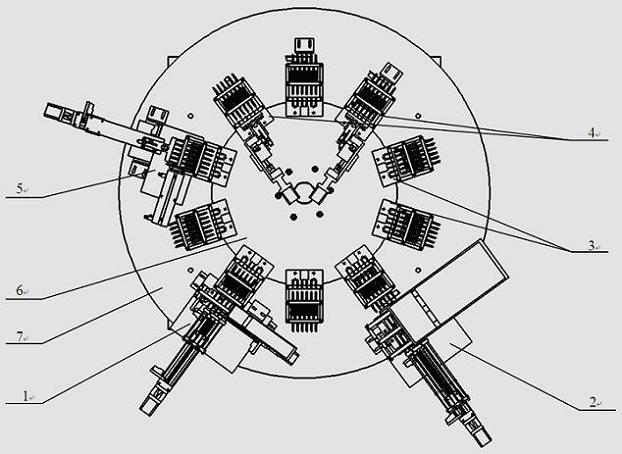

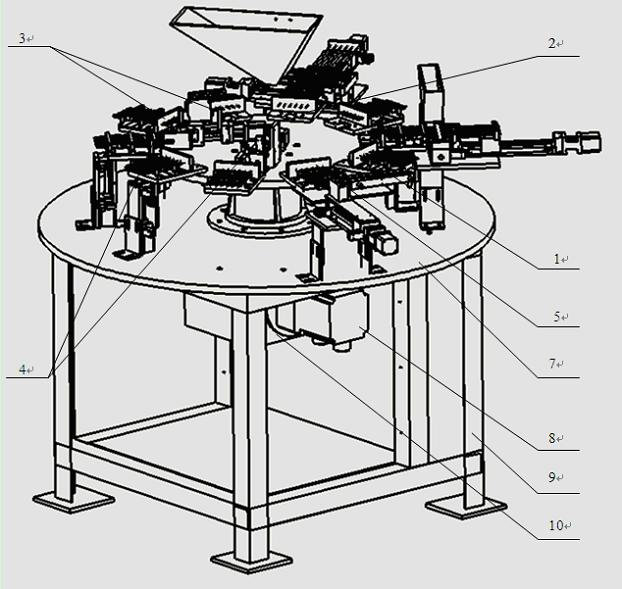

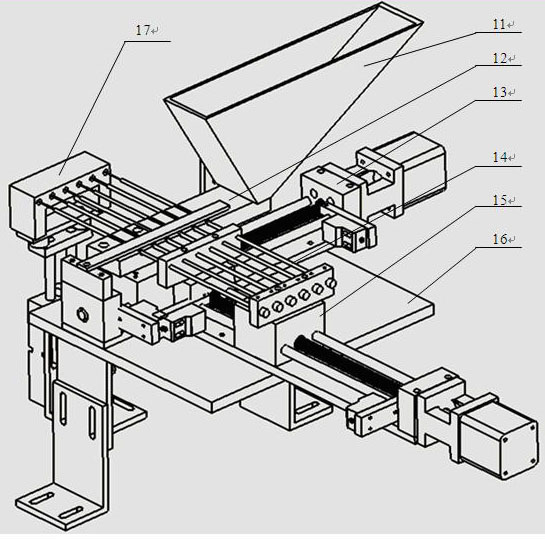

[0019] refer to figure 1 , figure 2 , a multi-station mercury thermometer turntable bubble receiving equipment, including a frame 9, a base plate 7, a transmission system, a turntable 6, an intelligent control platform and ten stations, the ten stations include an upper bubble tube 1, an upper triangle Material 2, preheating 3, bubble tube 4 and unloading 5 five processes. Among them, the turntable 6 is installed on the frame 9 through the main shaft, the transmission system is connected with the main shaft by the servo motor 8 and the reducer 10, the main shaft is fixed on the shaft sleeve through the bearing, the shaft sleeve is fixed on the base plate 7, and the base plate 7 is fixed On the frame 9, the structures of the five processes are respectively fixed on the base plate 7. The mechanical structures of the five processes of the equipment are respectively fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com