Method for achieving high purity separation and refinement by controlling morphology and particle size of 2, 6-dimethylnaphthalene crystals

A technology of dimethylnaphthalene and crystallization temperature, which is applied in crystallization purification/separation, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as complex procedures, high total fixed investment and production costs, and low yield , to achieve the effects of reducing fixed investment, simplifying operation and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

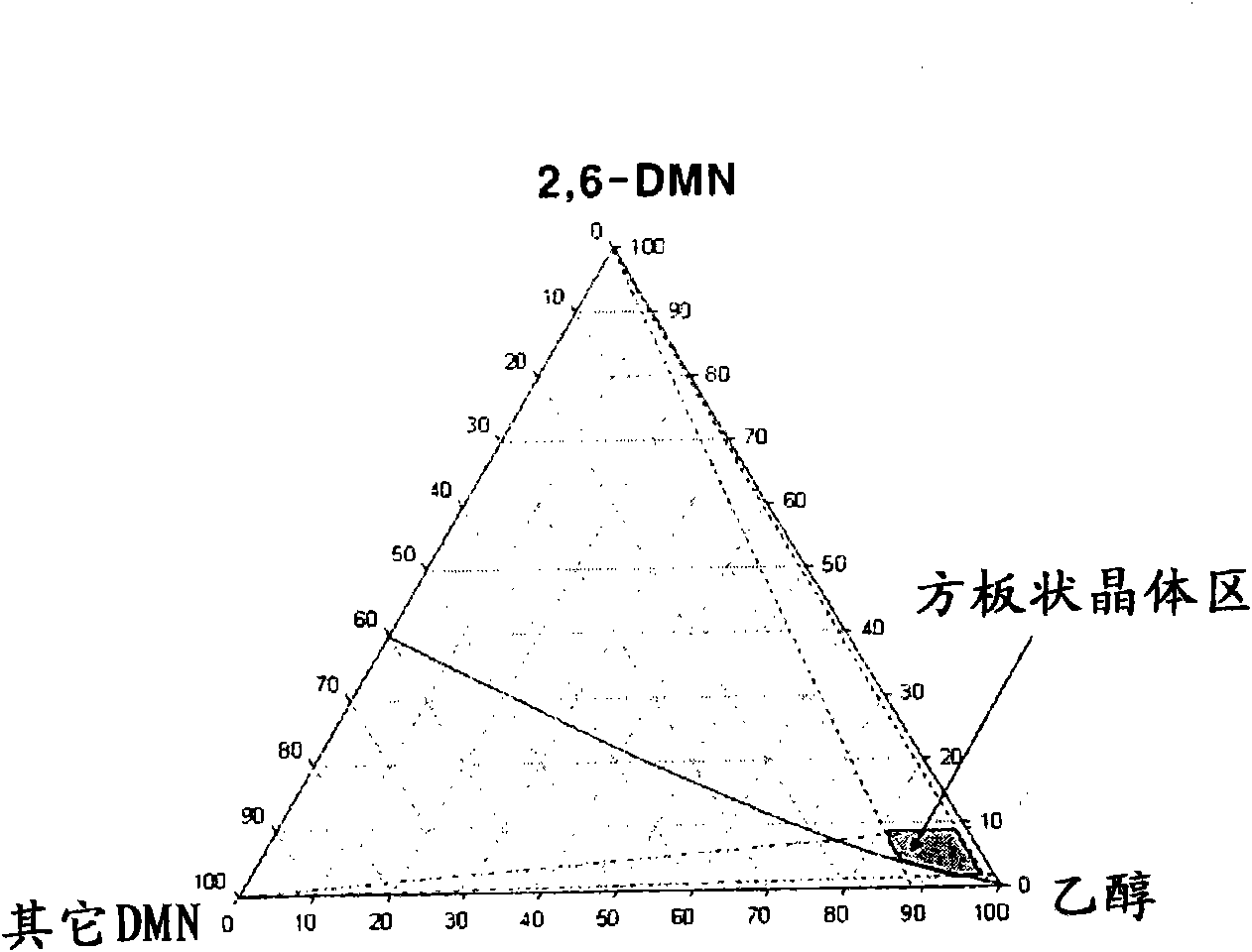

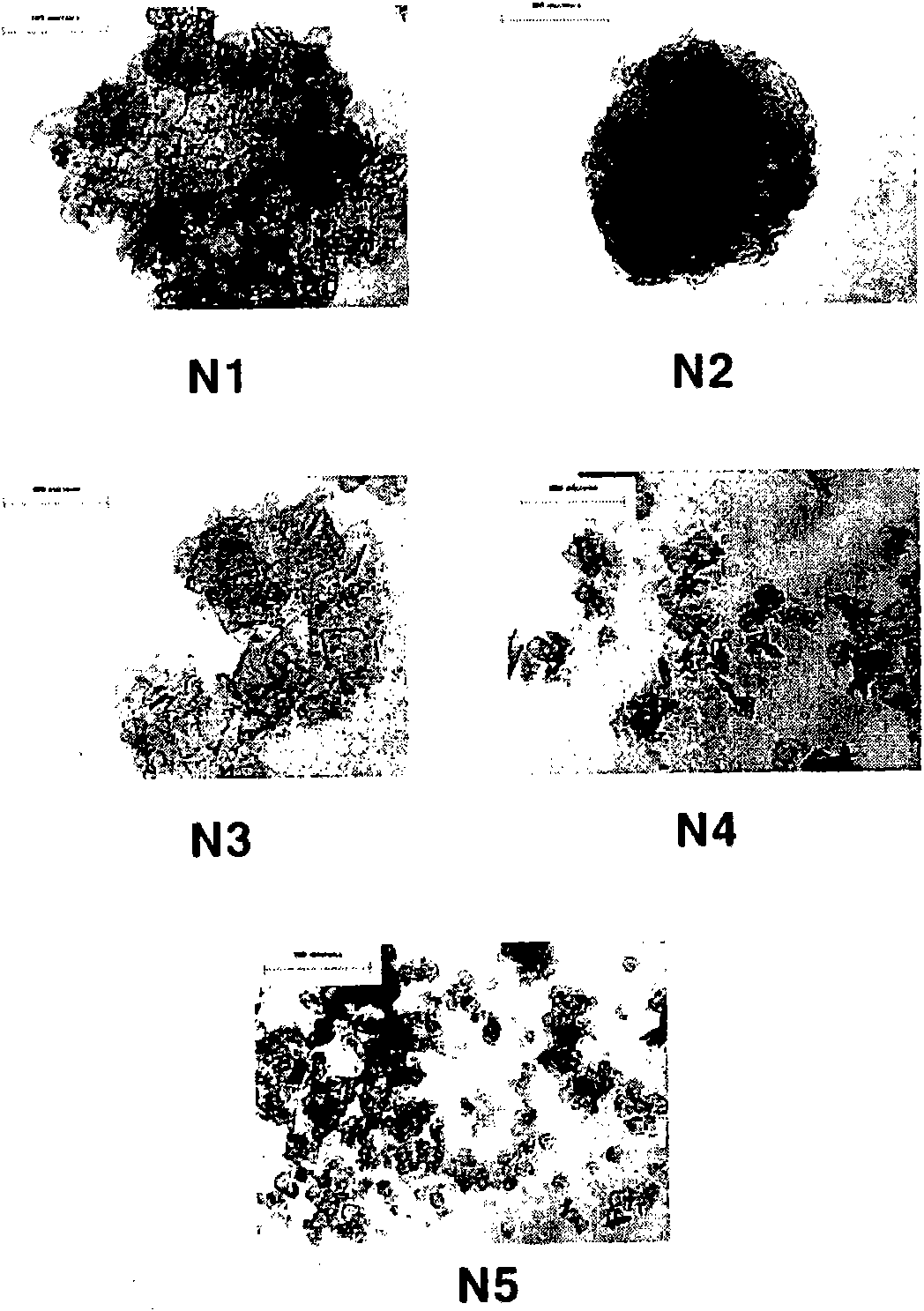

[0030] The 2,6-DMN of the present invention is obtained by: appropriately mixing and dissolving a mixture of dimethylnaphthalene isomers and a selected solvent according to the composition ratio; crystallizing by continuously transferring the obtained mixture to a crystallization unit and separation of 2,6-DMN crystals produced by appropriate controls from the mother liquor. According to the method of the present invention, one crystallization process enables the isolation and purification of high-purity 2,6-DMN with a purity greater than 99.0% by weight.

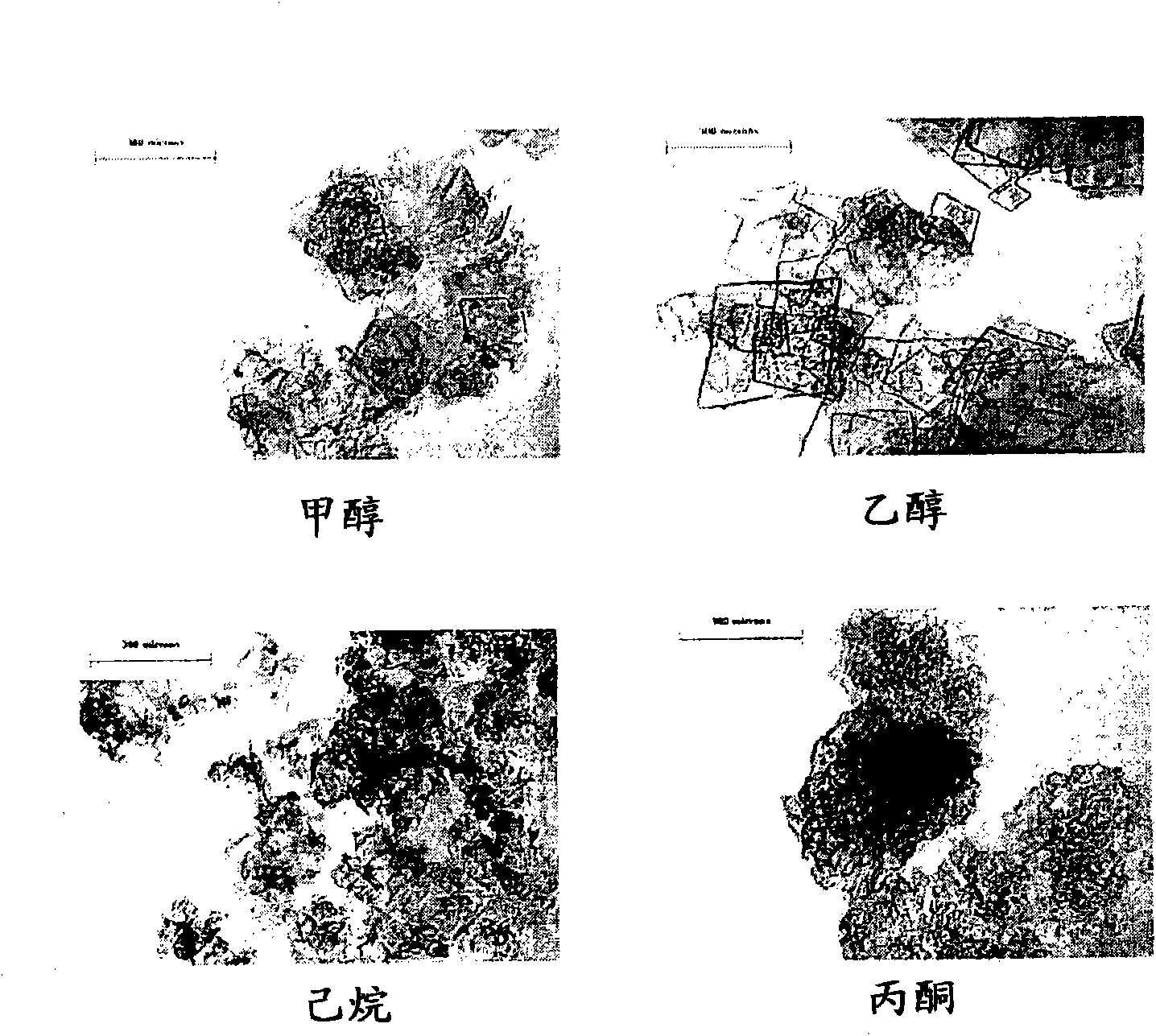

[0031]In general, in the crystallization process, the crystal morphology, which is one of the important characteristics of the crystal, should vary depending on the use of the crystal. Furthermore, controlling crystal morphology is a key means of isolating specific substances from mixtures. Specifically, by crystallization, isomers having similar boiling points can be easily separated, whereas separation of isomers is a di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com