Vertical anti-explosion bag filling machine

A bagging machine, vertical technology, applied in the field of vertical explosion-proof bagging machine, can solve the problems of slow bagging, waste of labor, not compact and compact, etc., to reduce water loss, reduce production costs, and increase nutrients. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

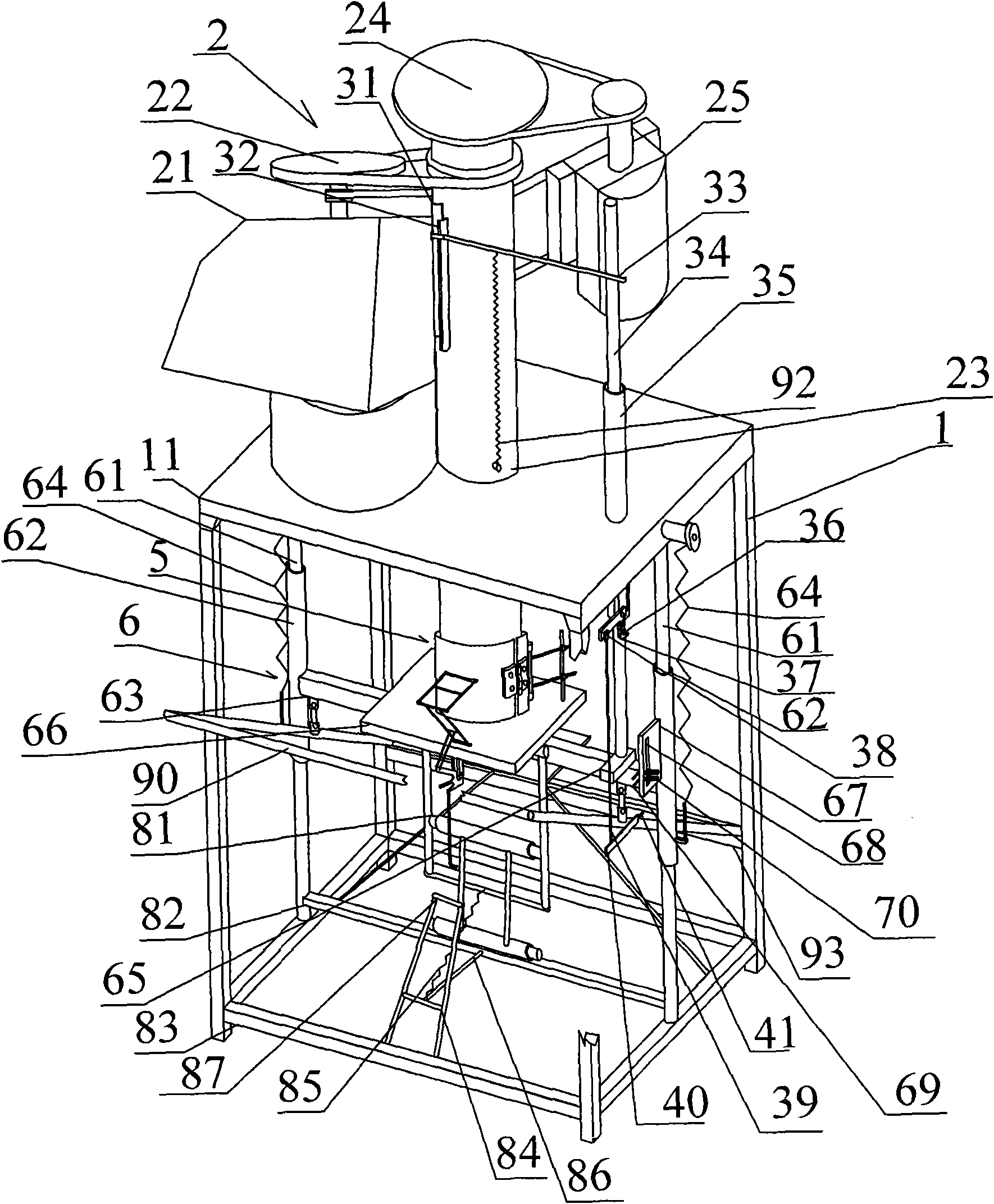

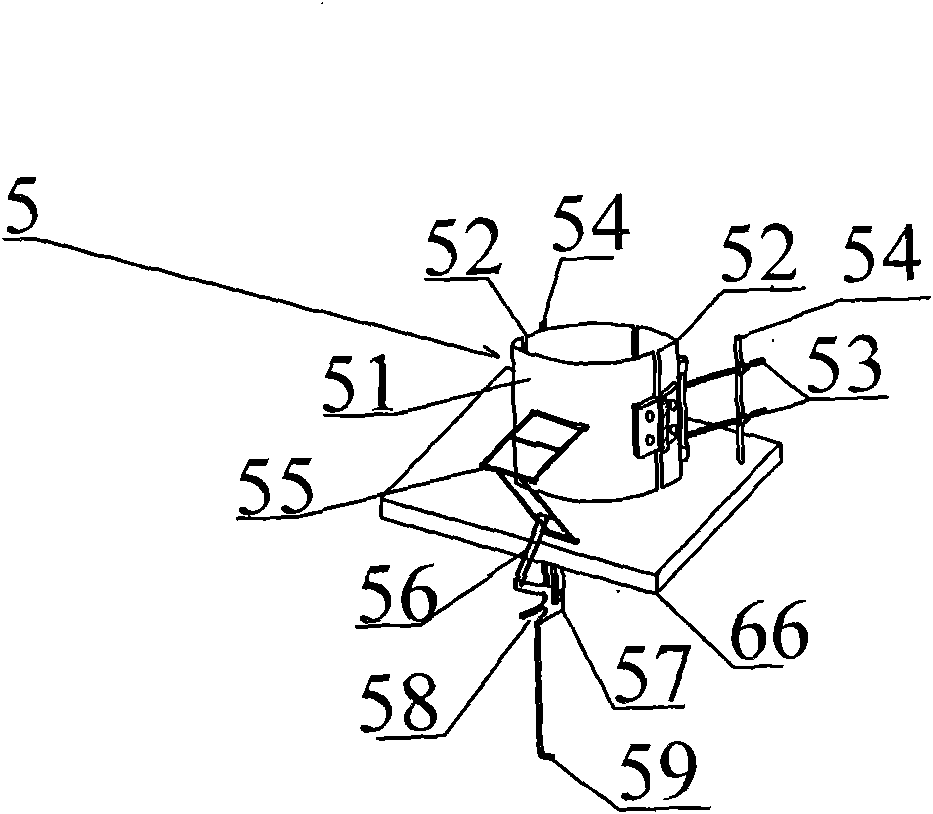

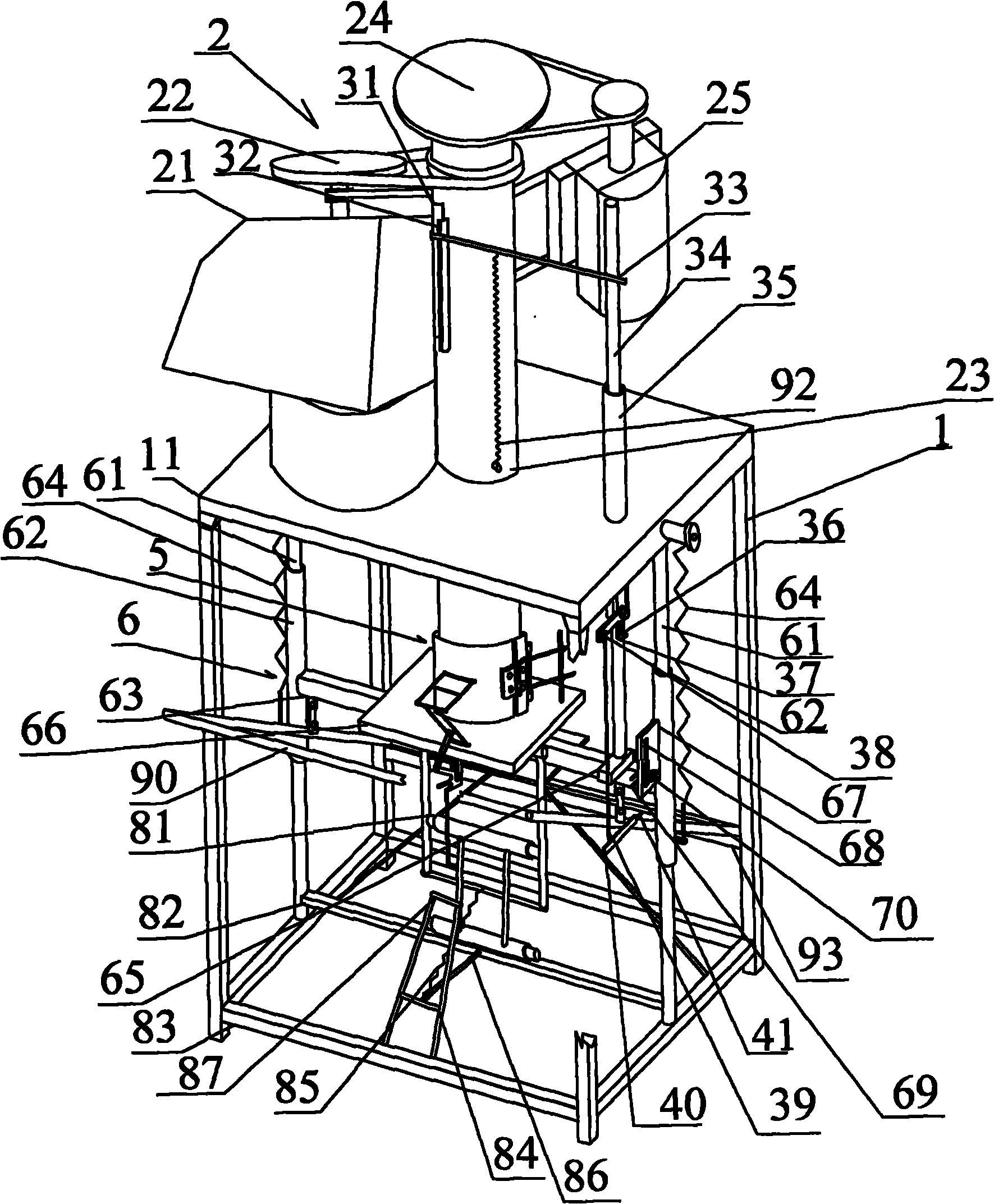

[0036] see figure 1 , figure 2Shown: the bagging machine of the present invention is made up of frame 1, feeding device 2, bagging cylinder 5 and lifting device 6, wherein feeding device 2 is located on the top plate 11 of frame 1, and feeding device 2 is made of hopper 21. The agitator 22 and the feeding pipe 23 are composed of a screw feeder 24 arranged in the feeding pipe 23. The outlet of the feeding pipe 23 is located at the lower part of the top plate 11. The agitator 22 and the screw feeder 24 are driven by a motor 25. The material inlet of the pipe 23 is provided with a material control valve 31, and both sides of the material control valve 31 are provided with slideways 32, the slideway 32 is fixed on the feeding pipe 23, and the material control valve 31 can slide up and down in the slideway 32 , to control feeding and stopping, the back of the material control valve 31 is fixed with a pull rod 33, a spring 92 is arranged between the pull rod 33 and the feeding pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com