Preparation method of crisp mushroom food and processing equipment thereof

A processing equipment and technology of mushrooms, which is applied in the field of preparation of crispy mushroom food, can solve the problems of poor taste and low yield, achieve the effects of extending shelf life, overcoming high oil content, and being convenient to eat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

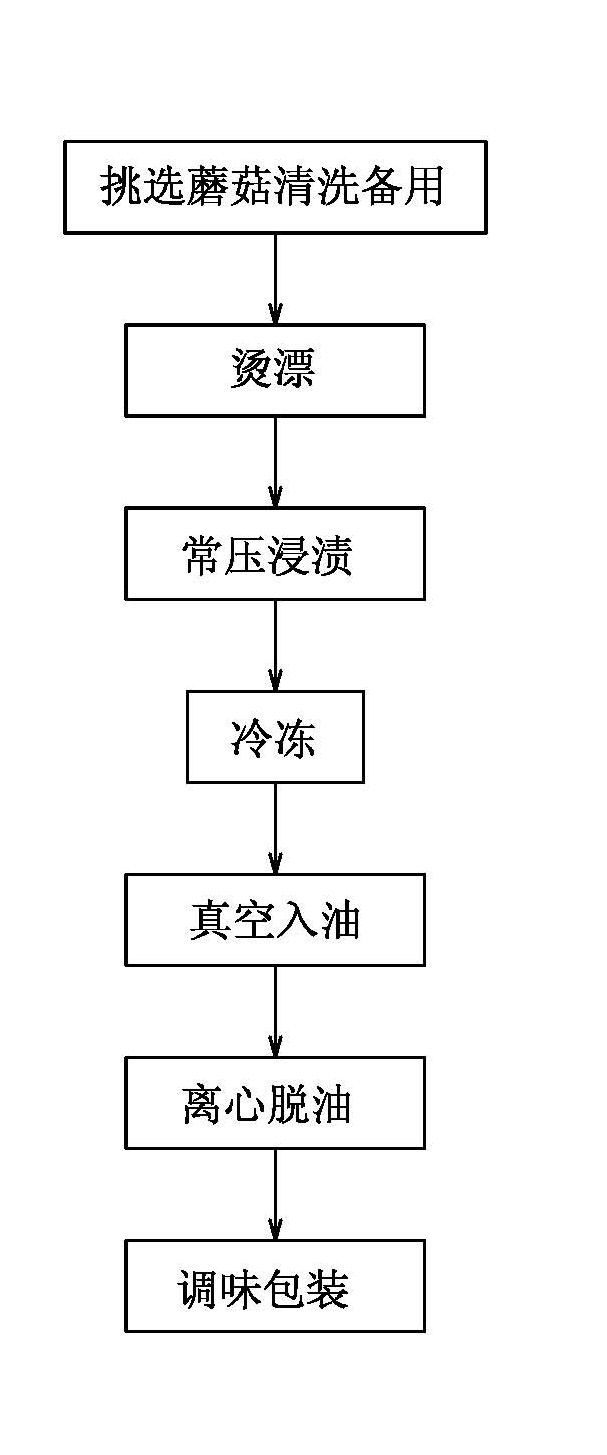

[0026] see figure 1 , is the method flowchart of the preparation method of the crispy mushroom food of the present invention and the processing equipment thereof. The preparation method of this crispy mushroom food, comprises the following steps:

[0027] a. Select fresh mushrooms with high quality and basically the same shape and size for cleaning and standby.

[0028] b. Put the mushrooms into water with a temperature of 95-100°C and blanch for 5-10 minutes.

[0029] c. Put the blanched mushrooms into an atmospheric pressure impregnation tank, fill in the impregnating material, and impregnate under atmospheric pressure for 90 to 120 minutes.

[0030] The dipping material in the above step c is a mixture of 5% to 10% white sugar, 0.5% to 5% salt, 1% to 10% dextrin, and 75% to 93.5% water. The dipping material gradually penetrates into the inside of the mushroom, and the processed crispy mushroom food has a better taste.

[0031] d. Take out the mushrooms in the atmospheri...

Embodiment 1

[0035] Embodiment 1: Select 10 kg of fresh mushrooms with high quality and substantially the same shape and size for cleaning, put them into water with a temperature of 95° C. for blanching for 10 minutes, then put the mushrooms into an atmospheric pressure dipping tank, and fill in 10 kg of dipping materials. In the dipping material, sugar 500g, salt 50g, dextrin 100g, water 9350g, impregnate at normal pressure for 120 minutes, make the dipping material gradually penetrate into the inside of the mushroom, then freeze for 90 minutes, then add vegetable oil in the vacuum drying tank, heat the oil temperature to 85 ℃, put the frozen mushrooms into the vegetable oil, vacuumize, put the oil into the vacuum for 20 minutes, and then degrease the mushrooms by centrifugation for 10 minutes after the vacuum into the oil, finally add seasonings and mix, and pack.

Embodiment 2

[0036] Embodiment 2: Select 10kg of fresh mushrooms with high quality and substantially the same shape and size for cleaning, put them into water with a temperature of 100°C for blanching for 5 minutes, then put the mushrooms into an atmospheric pressure dipping tank, fill in 10kg of dipping materials, and the 10kg In the dipping material, sugar 1000g, salt 500g, dextrin 1000g, water 7500g, impregnate at normal pressure for 90 minutes, make the dipping material gradually penetrate into the inside of the mushroom, then freeze for 60 minutes, then add vegetable oil in the vacuum drying tank, heat the oil temperature to 100 ℃, put the frozen mushrooms into the vegetable oil, vacuumize the oil for 10 minutes, then centrifugally deoil the mushrooms for 5 minutes after vacuuming the oil, add seasonings and mix, and pack.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap