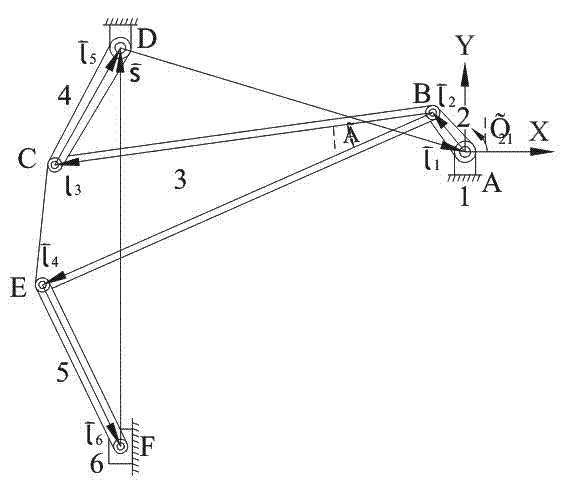

Triangular toggle-rod working mechanism of servo mechanical press and optimized design method thereof

A technology of servo machinery and working mechanism, which is applied to presses, computing machines, stamping machines, etc., and can solve problems such as suboptimal boost ratio, complex structure, and insufficient boost ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

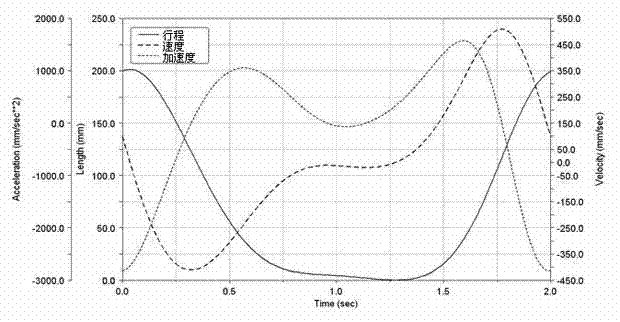

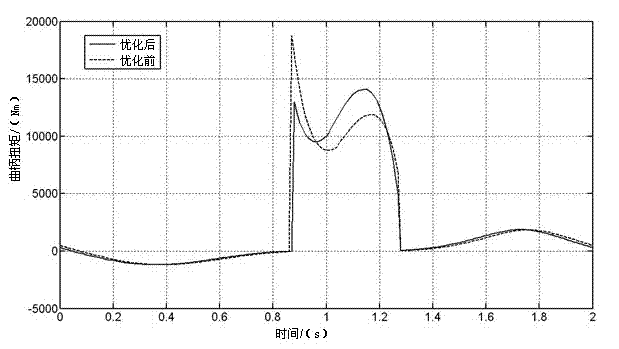

[0094] For the optimal design of the triangular toggle working mechanism of a servo mechanical press, the main design performance indicators are: the working stroke of the slider is 200mm, the nominal pressure Pg is 1600kN, and the nominal pressure point is 6mm. Other main design requirements include: the horizontal limit dimension Lh is 600mm, the longitudinal limit dimension Lv is 320mm, the maximum swing angle of the upper and lower toggles does not exceed 50°, and the maximum torque of the servo motor does not exceed 1500Nm.

[0095] According to the first, second and third steps of the implementation steps, given the initial values of 10 structural parameters (as shown in Table 1), the parametric virtual prototype model was established, and the parameter sensitivity analysis was carried out according to the fourth step. According to the analysis results (such as As shown in Table 1), the design variables determined for optimization are DV1, DV2, DV3, DV4, DV6, DV7, DV8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com