Pressure dewatering machine for sludge

A dehydrator and sludge technology, applied in dehydration/drying/concentrated sludge treatment, filtration separation, fixed filter element filter, etc., can solve the problems of low dehydration rate and unsatisfactory dehydration effect, and achieve simple overall structure , significant filtering effect and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

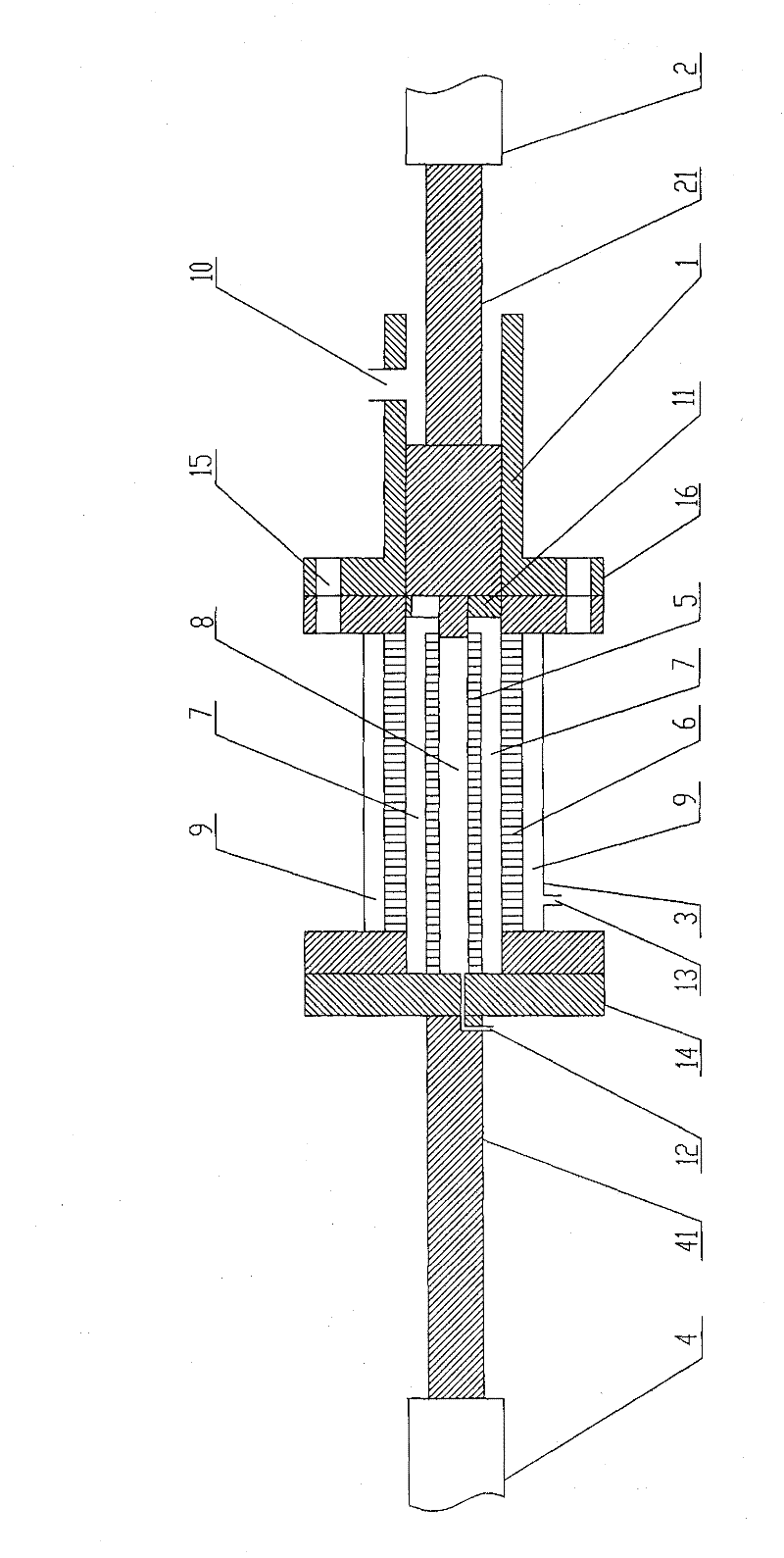

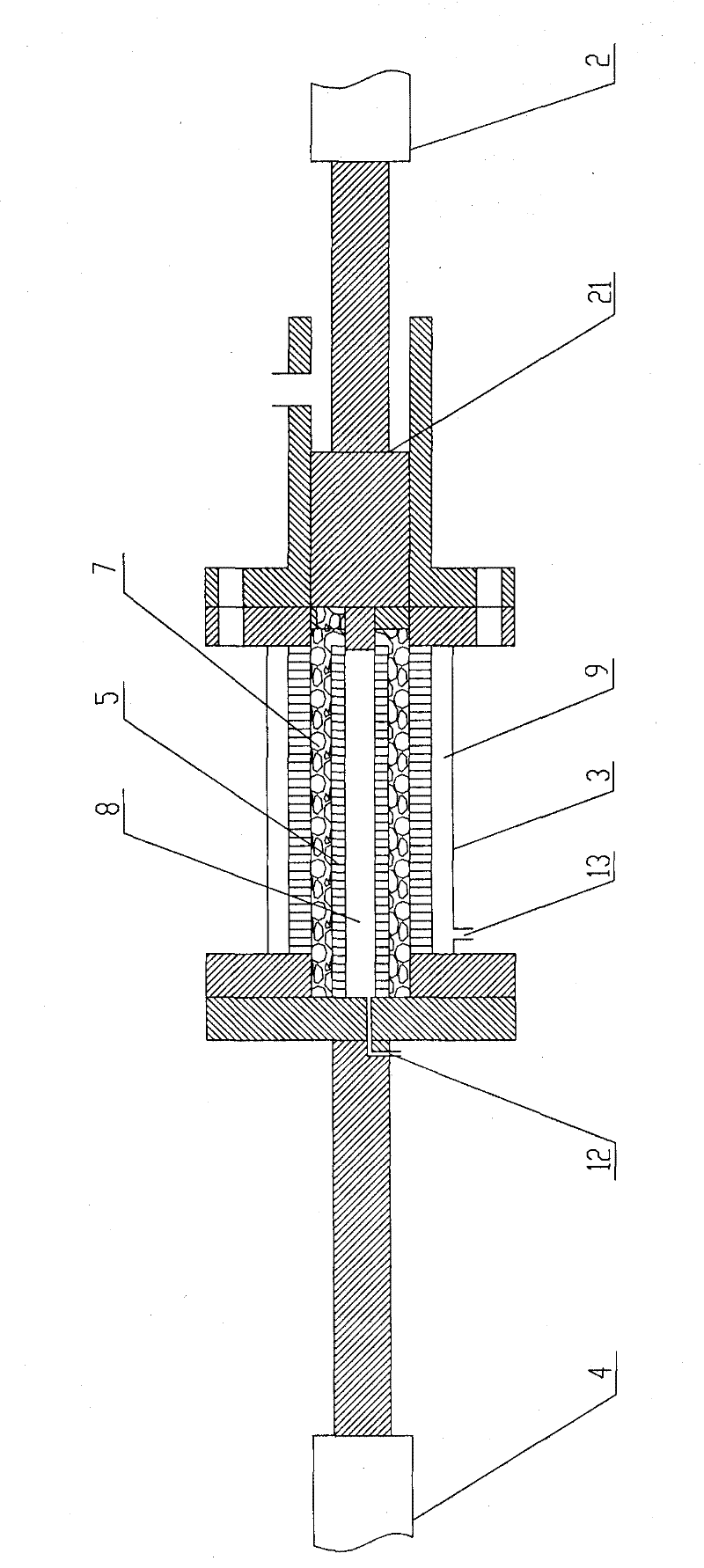

[0025] Such as Figure 1 ~ Figure 4 , Figure 6 , Figure 7 As shown, a sludge pressure dewatering machine includes the main components as follows:

[0026] Cylinder 1, feed cylinder 2, feed piston 21, filter cavity 3, discharge cylinder 4, discharge piston 41, inner filter 5, scraper 11, sealing end cover 14, flange 16.

[0027] A sludge pressure dehydrator, comprising a cylinder body 1 and a feed piston 21 arranged in the sludge cavity 17 inside the cylinder body 1, the end of the feed piston 21 is provided with a feed oil cylinder 2, and the feed oil cylinder 2 feeds The feed force of the feed piston 21 allows the feed piston 21 to move back and forth in the sludge cavity 17 in the cylinder body 1 .

[0028] The cylinder body 1 is connected with the filter chamber body 3 , and the cylinder body 1 and the filter chamber body 3 are provided with bolt holes 15 at corresponding positions, and are sealed and connected through the bolt holes 15 . A flange 16 is also provided ...

Embodiment 2

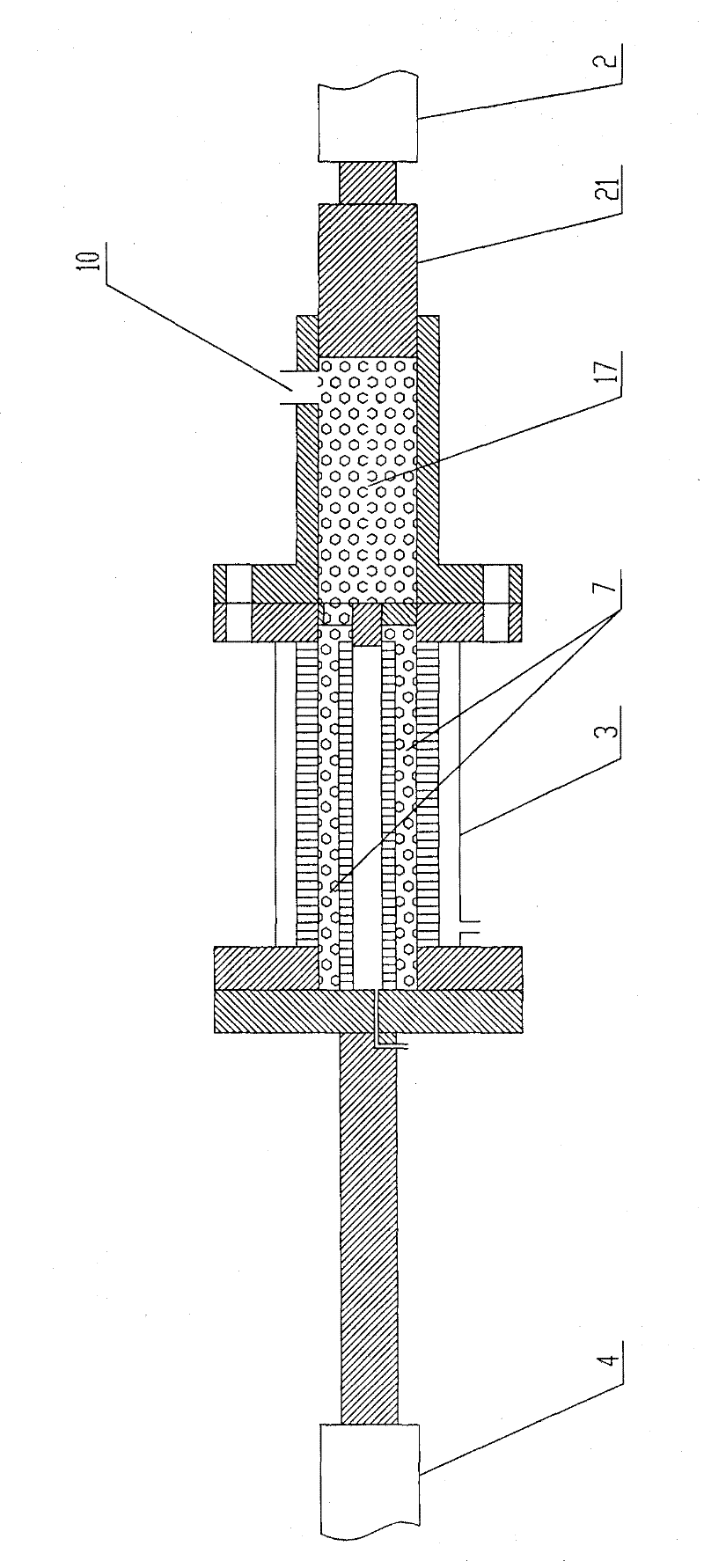

[0035] Such as Figure 1 to Figure 7 As shown, a sludge pressure dewatering machine includes the main components as follows:

[0036] Cylinder 1, feed cylinder 2, feed piston 21, filter chamber 3, discharge cylinder 4, discharge piston 41, inner filter 5, outer filter 6, mud scraper 11, sealing end cover 14, method Lan16.

[0037] The connection relationship of the above components is:

[0038] A sludge pressure dehydrator, comprising a cylinder body 1 and a feed piston 21 arranged in the sludge cavity 17 inside the cylinder body 1, the end of the feed piston 21 is provided with a feed oil cylinder 2, and the feed oil cylinder 2 feeds The feed force of the feed piston 21 allows the feed piston 21 to move back and forth in the sludge cavity 17 in the cylinder body 1 .

[0039]The cylinder body 1 is connected with the filter chamber body 3 , and the cylinder body 1 and the filter chamber body 3 are provided with bolt holes 15 at corresponding positions, and are sealed and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com