Low-temperature oil-water separation equipment for viscous oily sewage and its separation process

A technology for oil-water separation and oily-sewage water, applied in separation methods, liquid separation, water/sewage multi-stage treatment, etc., can solve the problems of difficult sewage leachation, poor fluidity at room temperature, low use effect, etc., and achieve good draining effect, The effect of low water content and easy layering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

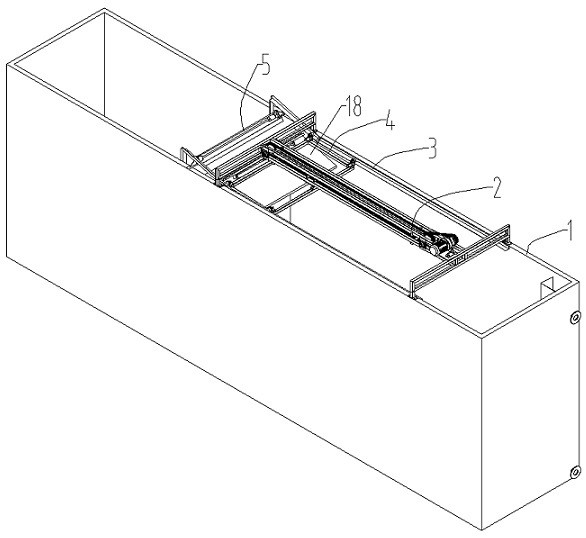

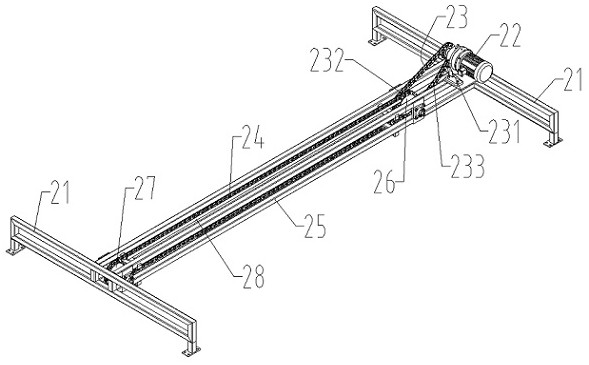

[0047] Example: such as Figure 1-Figure 13 As shown, a low-temperature oil-water separation equipment for viscous oily sewage includes a separation tank body 1, an upper port is provided above the separation tank body 1, and a driving rail 3 is installed on the separation tank body 1 near the upper port. , a walking oil scraping vehicle 4 is installed on the driving track 3, a scraper scraper system 5 is arranged on one side of the walking oil scraping vehicle 4, and a device for driving the walking oil scraping vehicle 4 to approach or Drive system 2 moving away from both sides of scraper blade system 5 .

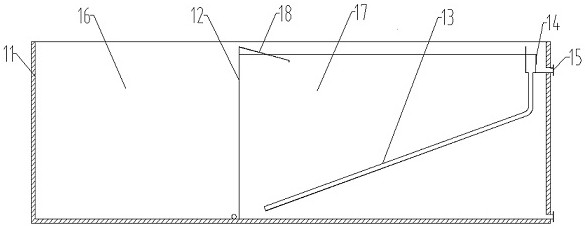

[0048] Such as Figure 1-Figure 2 As shown, the separation tank 1 includes a tank housing 11, a cavity is provided in the tank housing 11, a partition 12 is fixedly installed in the tank housing 11, and the partition 12 is used to separate the tank The cavity in the body shell 11 is divided into an oil-water separation tank 17 and an oil storage tank 16 .

[0049] The oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com