Cold and hot exchange device

A technology of cold and heat exchange and water cooling, which is applied in the direction of refrigerators, indirect heat exchangers, refrigeration and liquefaction, etc. It can solve the problem that heating and cooling appliances cannot reach the temperature when exhausting cold or heat, and the temperature of cold chips cannot be lowered or taken away quickly, etc. Problems, to achieve fast heat transfer, environmental protection and economy, and increase the effect of practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The detailed description and technical content of the present invention are described below with accompanying drawings. However, the attached drawings are provided for reference and illustration only, and are not intended to limit the present invention.

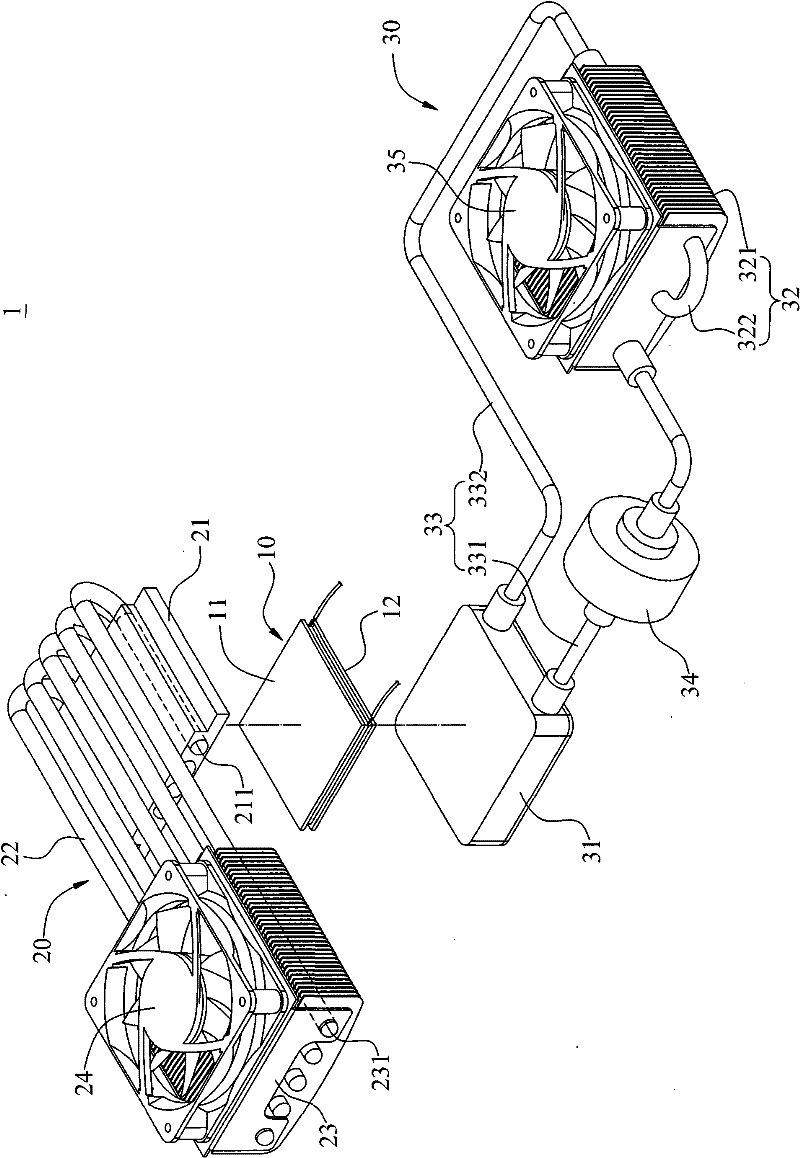

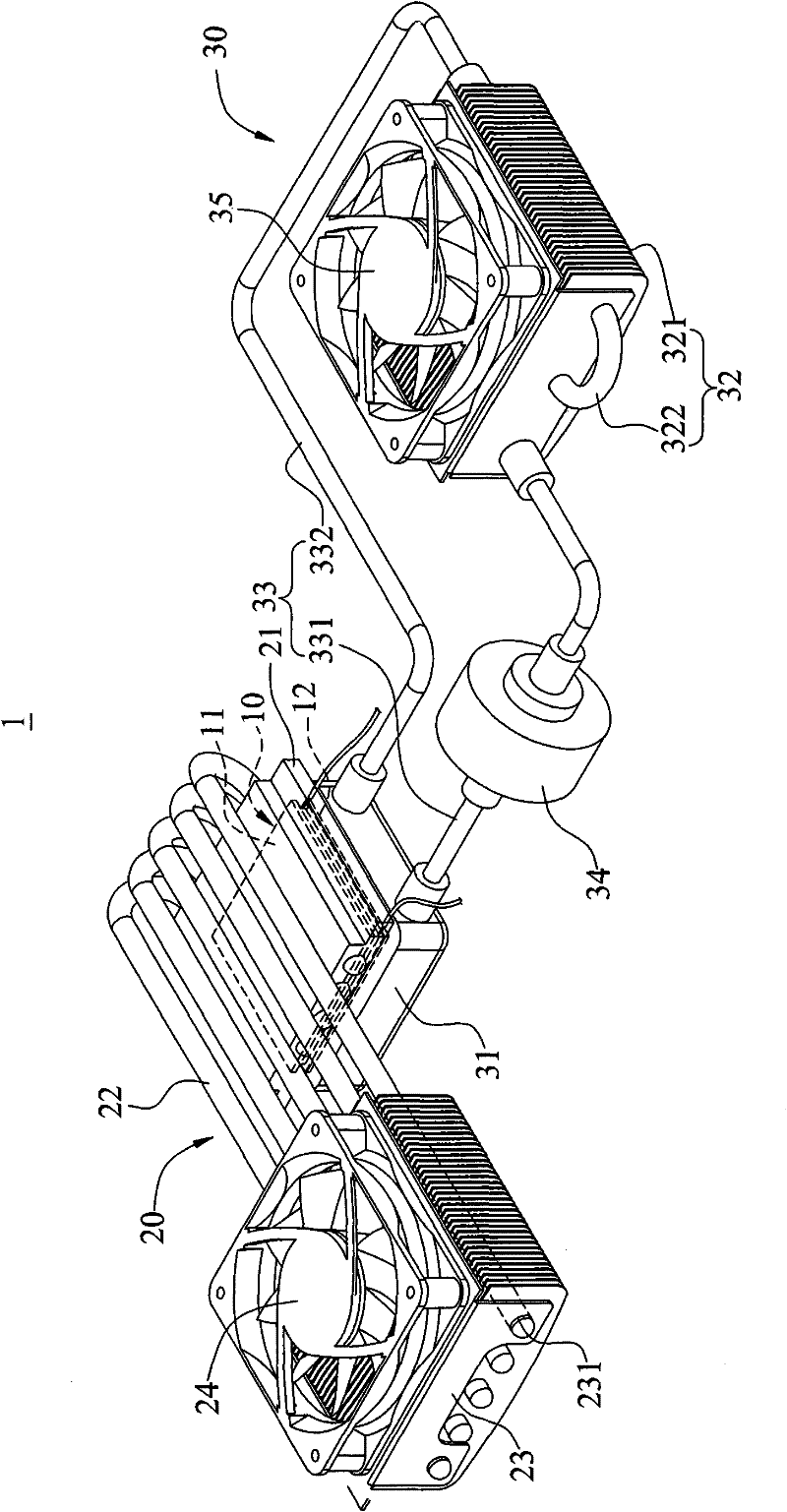

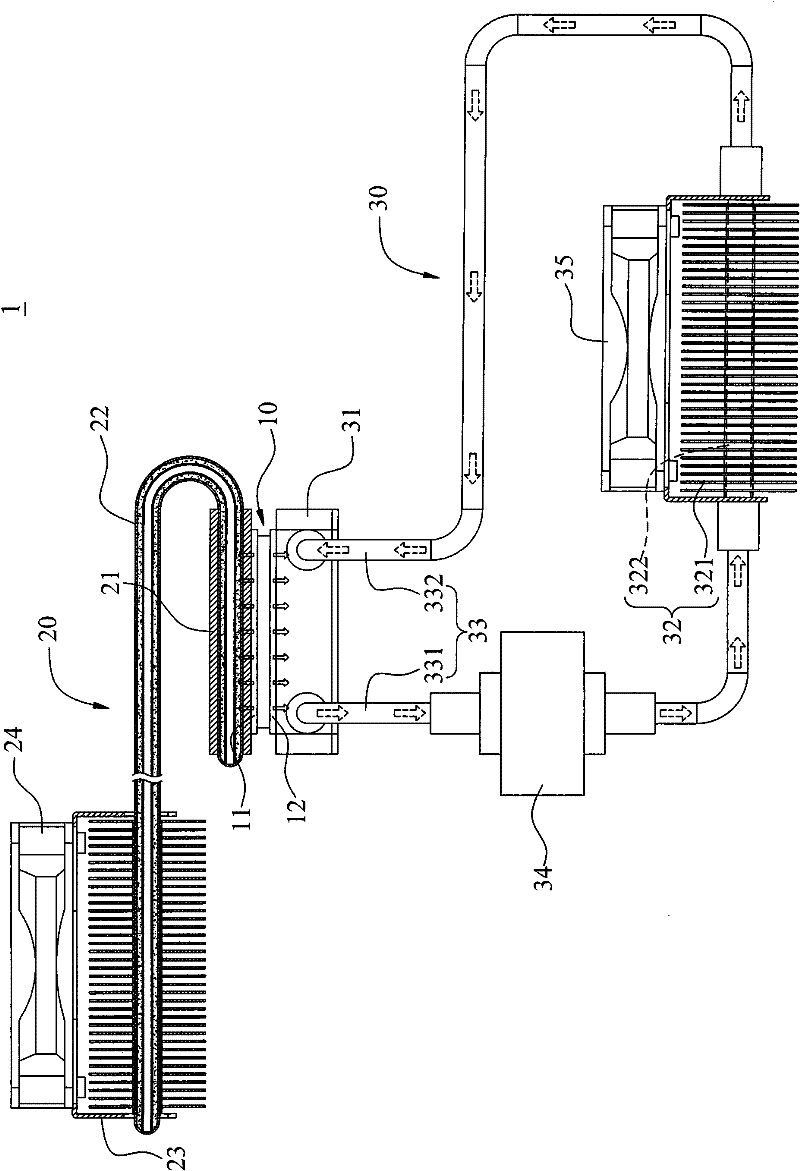

[0033] Please refer to Figure 1 to Figure 3 , are respectively an exploded schematic diagram, a three-dimensional schematic diagram and a combined cross-sectional schematic diagram of the cold and heat exchange device of the present invention; the cold and heat exchange device 1 of the present invention includes a thermoelectric cooling chip (Thermoelectric Cooling Chip) 10, a first conduction module 20 and a second conduction module 30.

[0034] The thermoelectric cooling chip (hereinafter referred to as the cooling chip) 10 is made of thermoelectric conversion material. After the current is supplied to operate, the temperature of one end surface will rise to form a hot end surface 11, and the temperature of the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com