Testing and ageing adapter for semiconductor laser

An adapter and laser technology, used in semiconductor lasers, single semiconductor device testing, lasers, etc., can solve problems such as performance fluctuations of laser monomers, increase in return rates, and lower yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

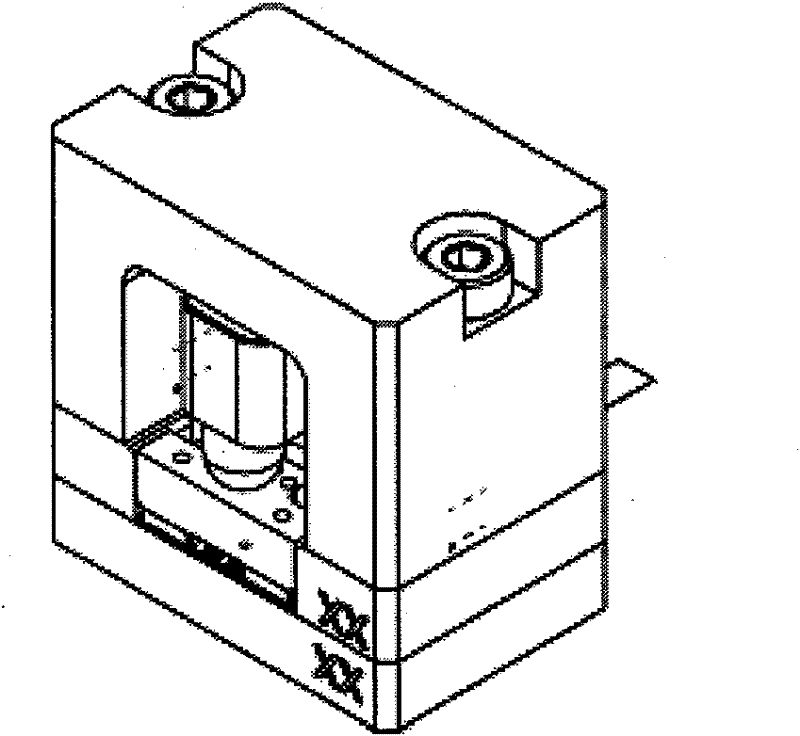

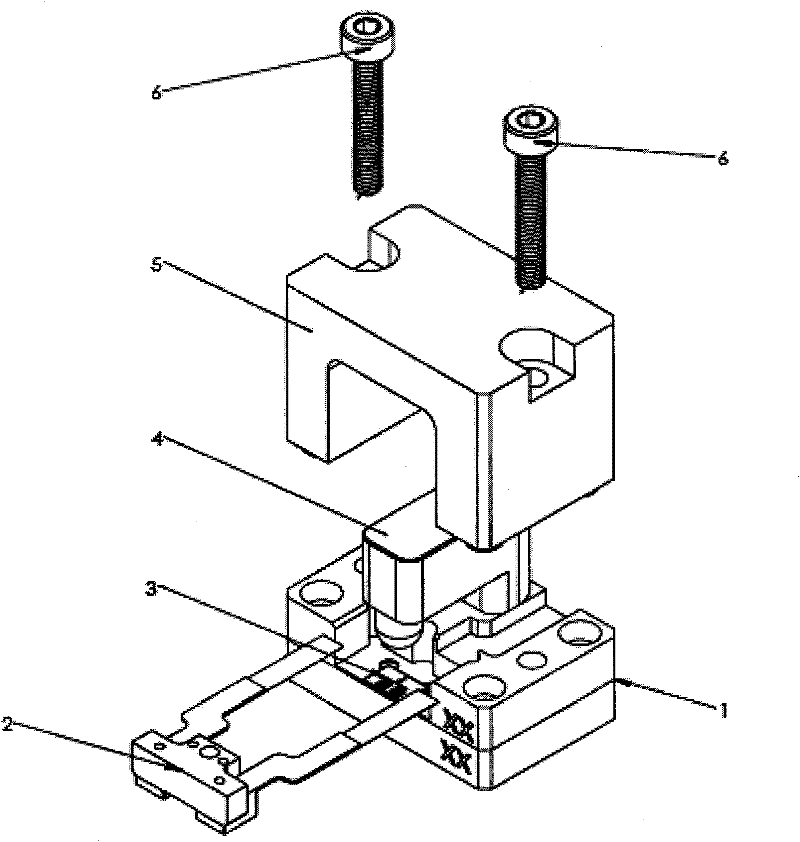

[0026] Such as Figure 1-9 As shown, a semiconductor laser test and burn-in adapter includes an adapter base 1, an adapter electrode 2, a semiconductor laser 3, a spring pressure head 4, an adapter cover 5, and cover fastening bolts 6. The semiconductor laser 3 is placed on the adapter base In the middle of 1, the semiconductor laser 3 is fixed and pressed by the adapter electrode 2 and the spring pressure head 4 above, and the adapter cover 5 provides mechanical protection for the adapter base 1, the adapter electrode 2, the semiconductor laser 3, and the spring pressure head 4. At the same time Provides a pressurized platform for diode laser testing and burn-in to ensure uniform cooling of adapter base 1.

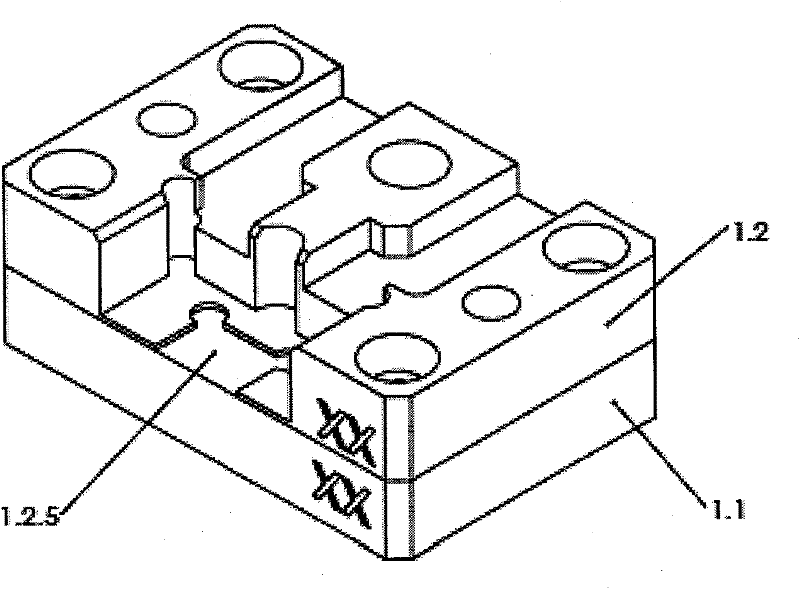

[0027] The adapter base 1 is composed of a lower half 1.1 and an upper half 1.2. After the lower half 1.1 and the upper half 1.2 are assembled, a rectangular opening 1.2.5 is formed for the semiconductor laser 3 to use. The lower half 1.1 is a cube, and a threaded hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com