Omnibearing lighting LED (light-emitting diode) packaging method and LED packaging part

A technology of LED packaging and LED packaging body, which is applied in semiconductor devices of light-emitting elements, components of lighting devices, cooling/heating devices of lighting devices, etc., and can solve problems such as blocking light and reducing the light output rate of light-emitting diodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

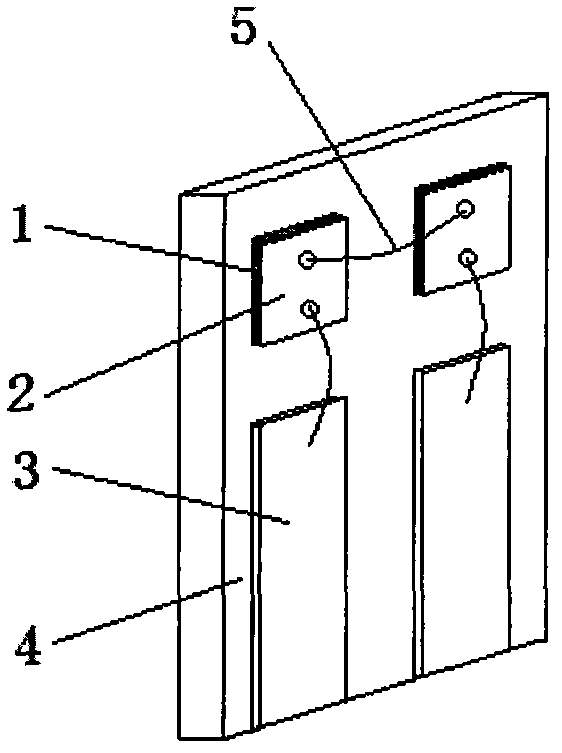

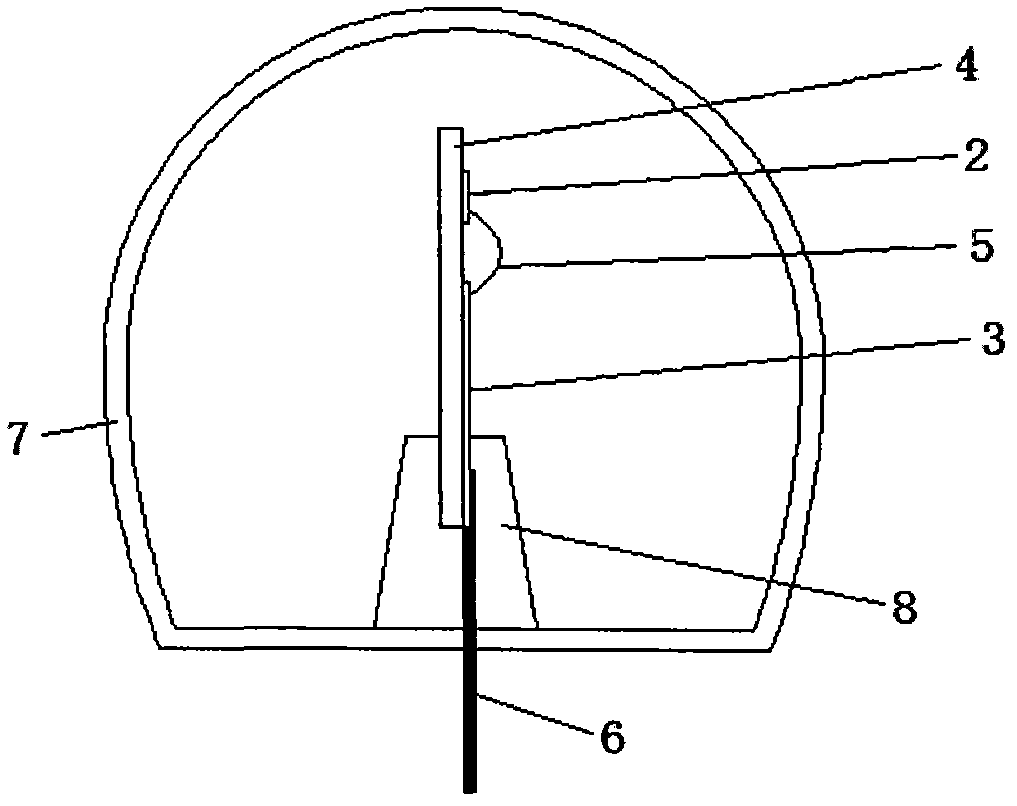

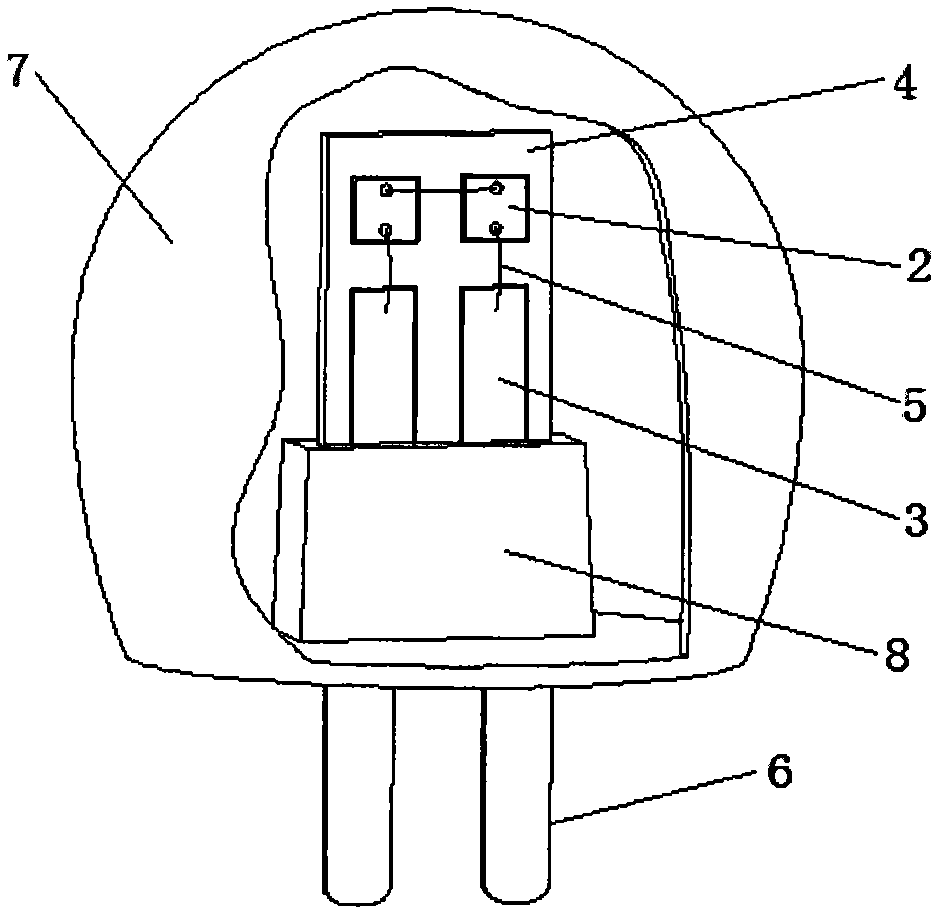

[0029] The present invention will be described in detail below with reference to the accompanying drawings. first reference figure 1 , which schematically shows the transparent bracket according to the first embodiment of the present invention. Such as figure 1 As shown, the main body of the transparent bracket is one or more pieces of transparent material 4, such as transparent glass or transparent film, and its thickness is about 0.4 mm to 5 mm. One or more LED chips 2 and one or more electrodes 3 are fixed on one side of the transparent glass or transparent film through a transparent die-bonding glue 1 . The electrical interconnection between chips and between chips and electrodes is realized through bonding wires 5 , which are preferably conventional bonding gold wires, and of course other metal or alloy power supply wires can also be used. It should be understood that although two LED chips connected in series are shown, the present invention is not so limited, and emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com