Cushion element, in particular a seat cushion element or a headrest cushion element of different hardness zones for use in a motor vehicle, method for producing a cushion element, and vehicle seat or headrest

A technology for motor vehicles and seat pads, which is applied in vehicle seats, vehicle parts, special positions of vehicles, etc., and can solve problems such as expensive and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] FIG. 1 schematically shows a generic vehicle seat 10 in side view. The vehicle seat 10 comprises a seat part 5 and a backrest part 6 each comprising padding and / or upholstery elements 11 covering a support structure of the seat or backrest part, the support structure being made of metal or plastic and the padding and / or upholstery elements for improving seating comfort.

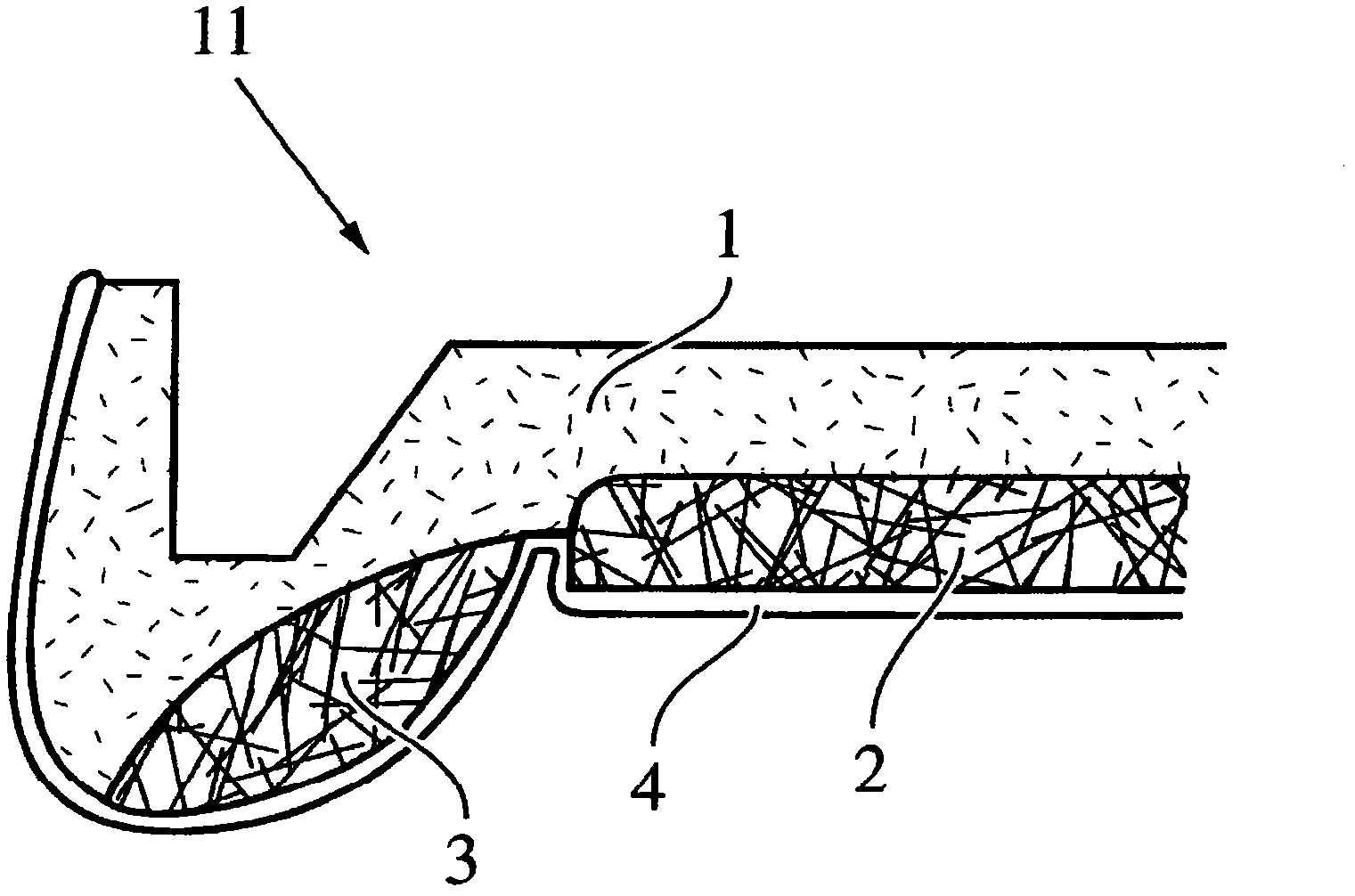

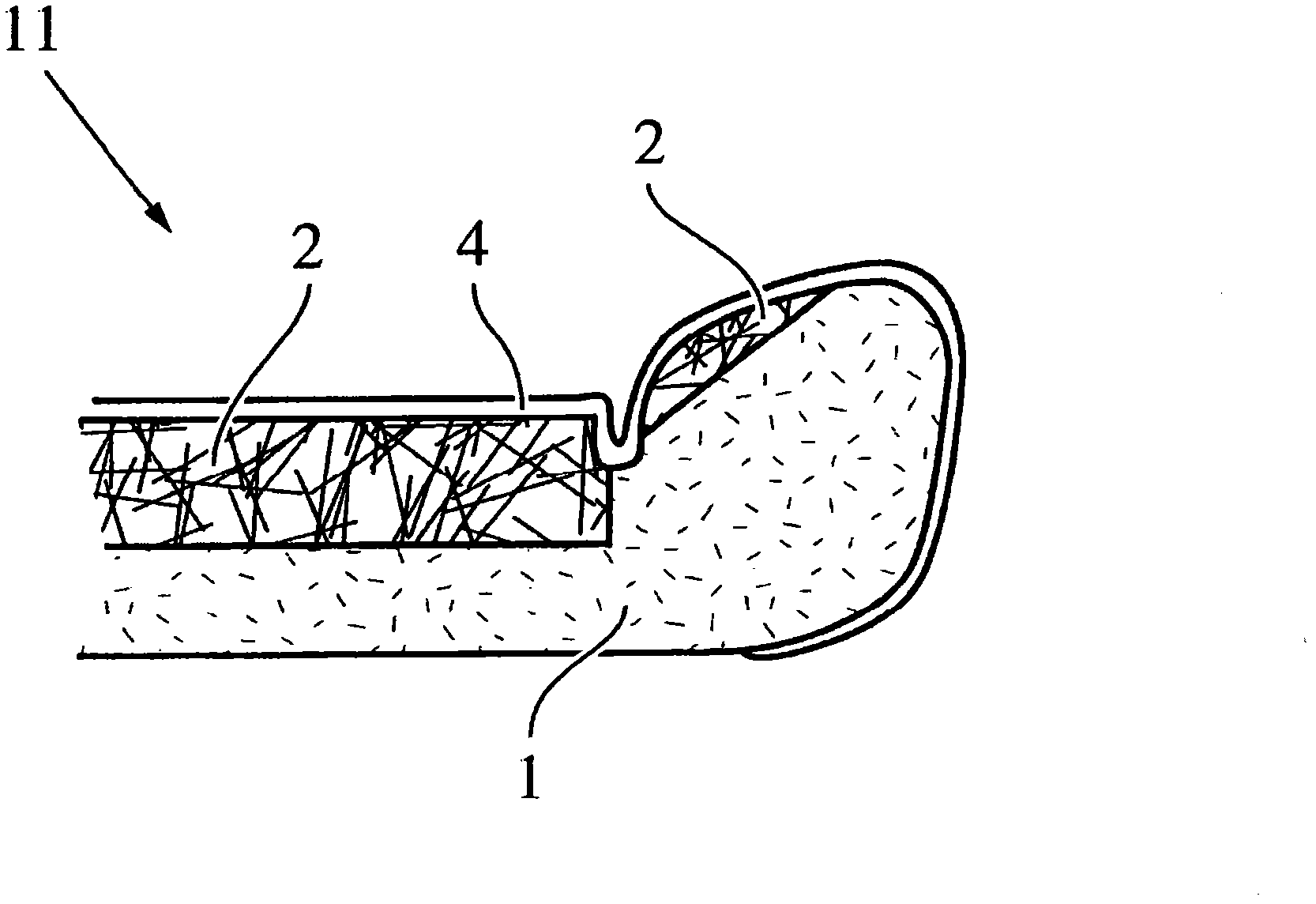

[0023] 2 and 3 each schematically show an embodiment of an upholstery element 11 of a vehicle seat 1 according to the invention for a seat and / or backrest part 5 , 6 in a sectional view. The cushion element 11 has a fiber composite material 1 and a nonwoven layer 4 . On the side of the nonwoven layer 4 facing the fiber composite material 1 , an insert material 2 , 3 is arranged in a cushion element 11 according to the invention.

[0024] FIGS. 4 and 5 each show an embodiment of a head restraint 7 comprising an upholstery element according to the invention and a shaped body 12 . Such a headrest 7 pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com