Parallel multi-output micro-transmission

A transmission and multi-output technology, applied to components with teeth, belts/chains/gears, transmission boxes, etc., can solve problems such as small transmission ratio, low precision, and large volume

Active Publication Date: 2011-07-27

SOUTH CHINA UNIV OF TECH

View PDF3 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Conventional gear transmissions are low in cost, stable in operation, low in noise, and large in transmission torque, but their transmission ratio is small and their mass is large, so they are rarely used in micro-machines

The worm transmission has a self-locking function, the transmission ratio is large, the input shaft and the output shaft are not on the same axis or on the same plane, but generally the volume is large, the transmission efficiency is low, and the precision is not high

The planetary gear transmission has compact structure, stable operation, high precision and strong bearing capacity, but the structure is more complicated and

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

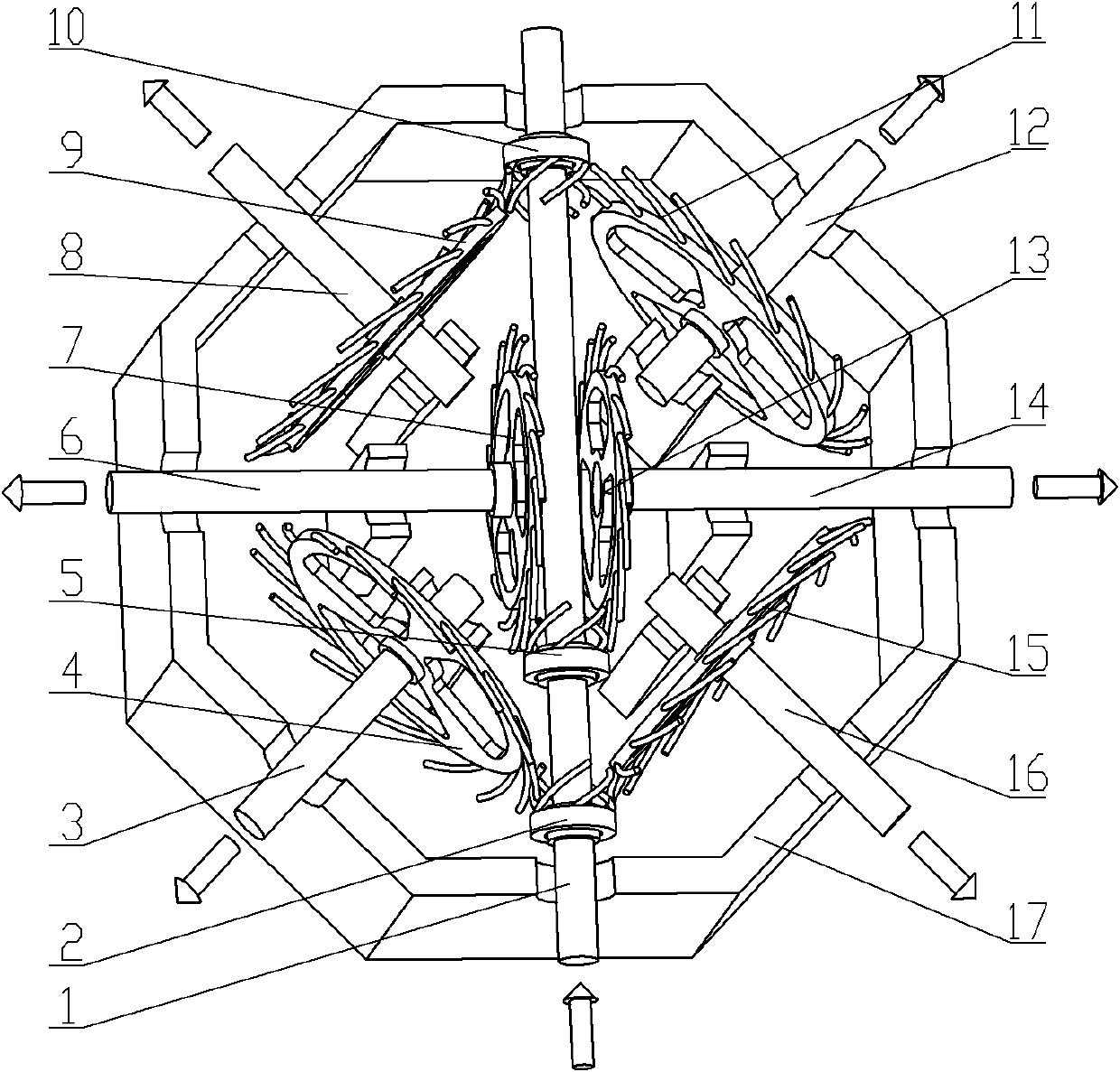

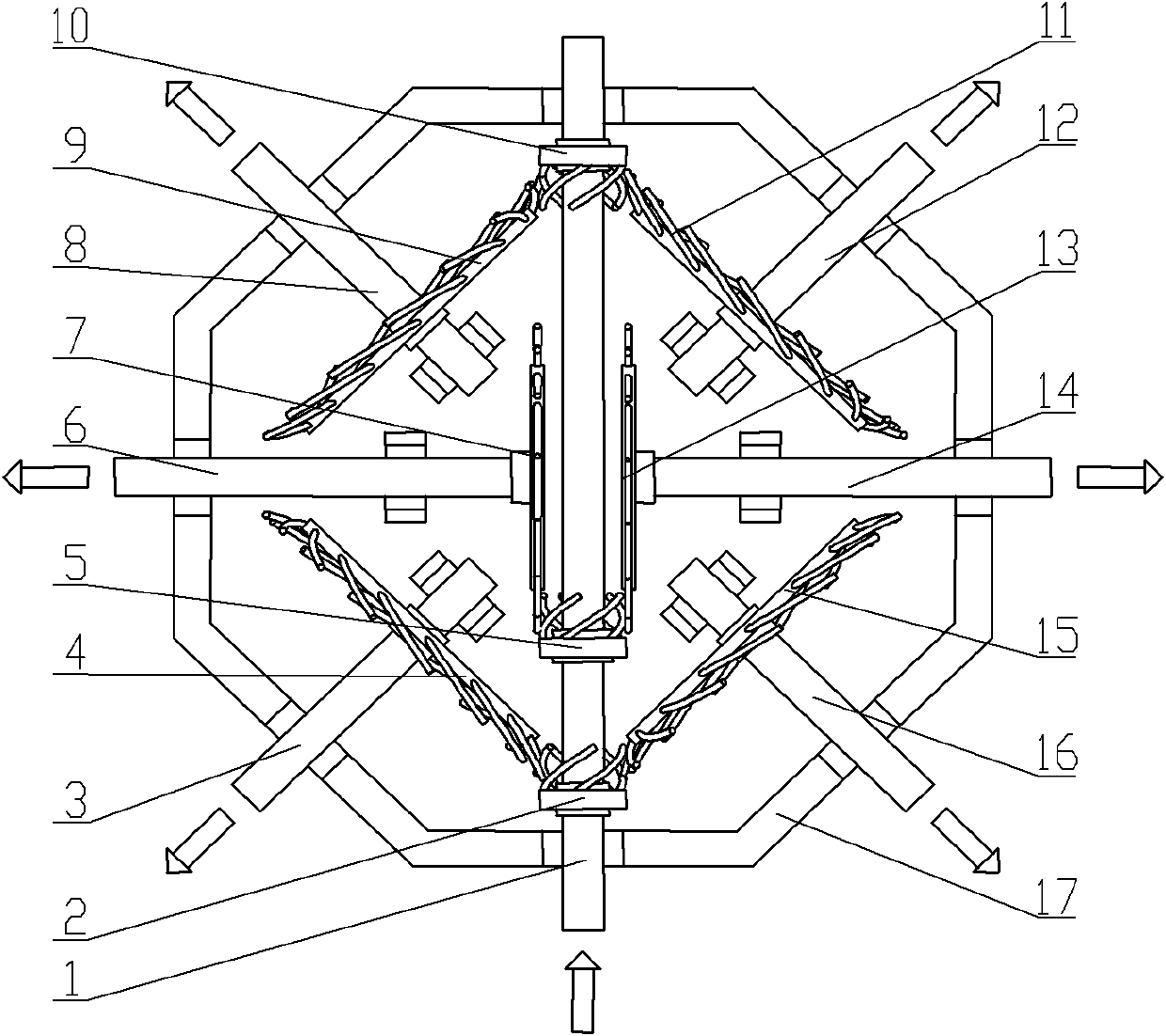

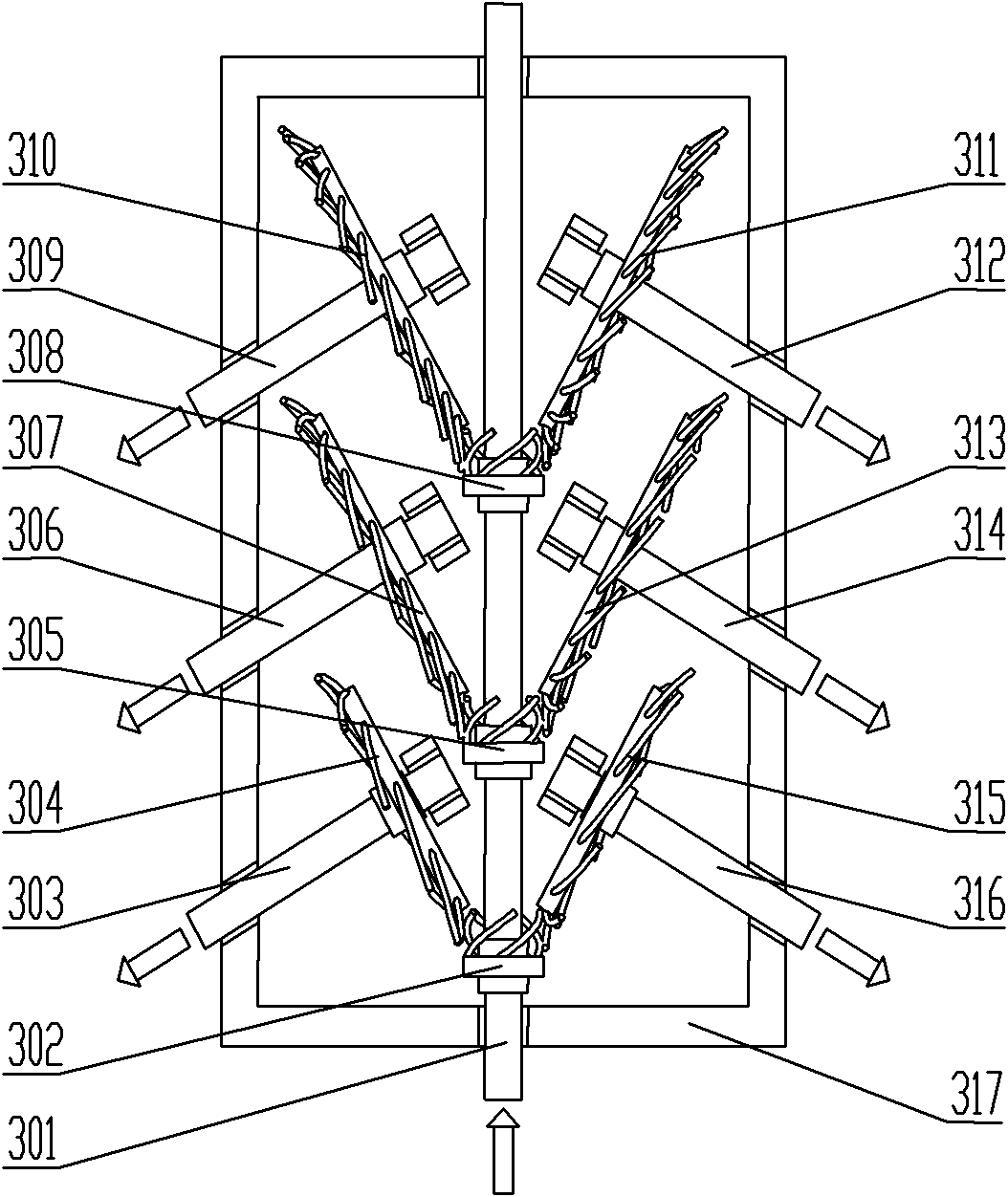

The invention provides a parallel multi-output micro-transmission. A transmission mechanism of the micro-transmission is a gear mechanism that is based on the spatial curve engaging principle. The micro-transmission can realize the outputting of many shafts simultaneously; and furthermore, an included angle between the central line of an input shaft and the central line of each output shaft can be any angle. The spatial curve engaging gear mechanism consists of driving wheels and driven wheels; a plurality of driving wheels are arranged on the input shaft; each output shaft is provided with one driven wheel; the output shafts are symmetrically arranged at two sides of the input shaft; a motor is connected with the input shaft and drives the input shaft and the driving wheels on the input shaft to rotate; and the driving wheels drive the driven wheels to rotate, thereby realizing the outputting of many shafts simultaneously. The parallel multi-output micro-transmission is a primary micro-transmission, is characterized in that the structure is simple, a box body is simple, the speed ratio is large, the layout is compact, the application is flexible, the weight is extremely light, the cost is low, the multi-shaft output is realized, and the like, has wide application prospect in the application occasions with the conditions of flexible operation, multi-direction output, multiple transmission ratios and the like, and is convenient for manufacturing abundant and flexible products.

Description

technical field [0001] The invention relates to the design of a space curve meshing wheel transmission mechanism and a micromechanical system, in particular a parallel multi-output micro transmission that realizes multi-speed ratio and multi-output transmission by using a space curve meshing wheel as a transmission mechanism. Background technique [0002] Micromechanical devices (1-100mm) and micro-mechanical devices (10μm-1mm) are one of the development trends of mechanics. One of the main performances of micromachines and micromachines is to realize the continuous motion transmission of small power in a small space. [0003] At present, the main micro-mechanical transmission technologies researched and developed at home and abroad are: the traditional mechanical transmission mechanism is directly miniaturized, but the structure is complex, the cost is high, and the manufacturing is difficult; the non-traditional mechanical micro-drive technology is only suitable for the in...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16H49/00F16H57/02

Inventor 陈扬枝傅小燕丁江

Owner SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com