Postposition type plasma cleaning device

A plasma, rear-mounted technology, used in heating methods, household heating, lighting and heating equipment, etc., can solve the problems of high wind resistance, unsatisfactory dust removal and sterilization area and effect, and short dust collection distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

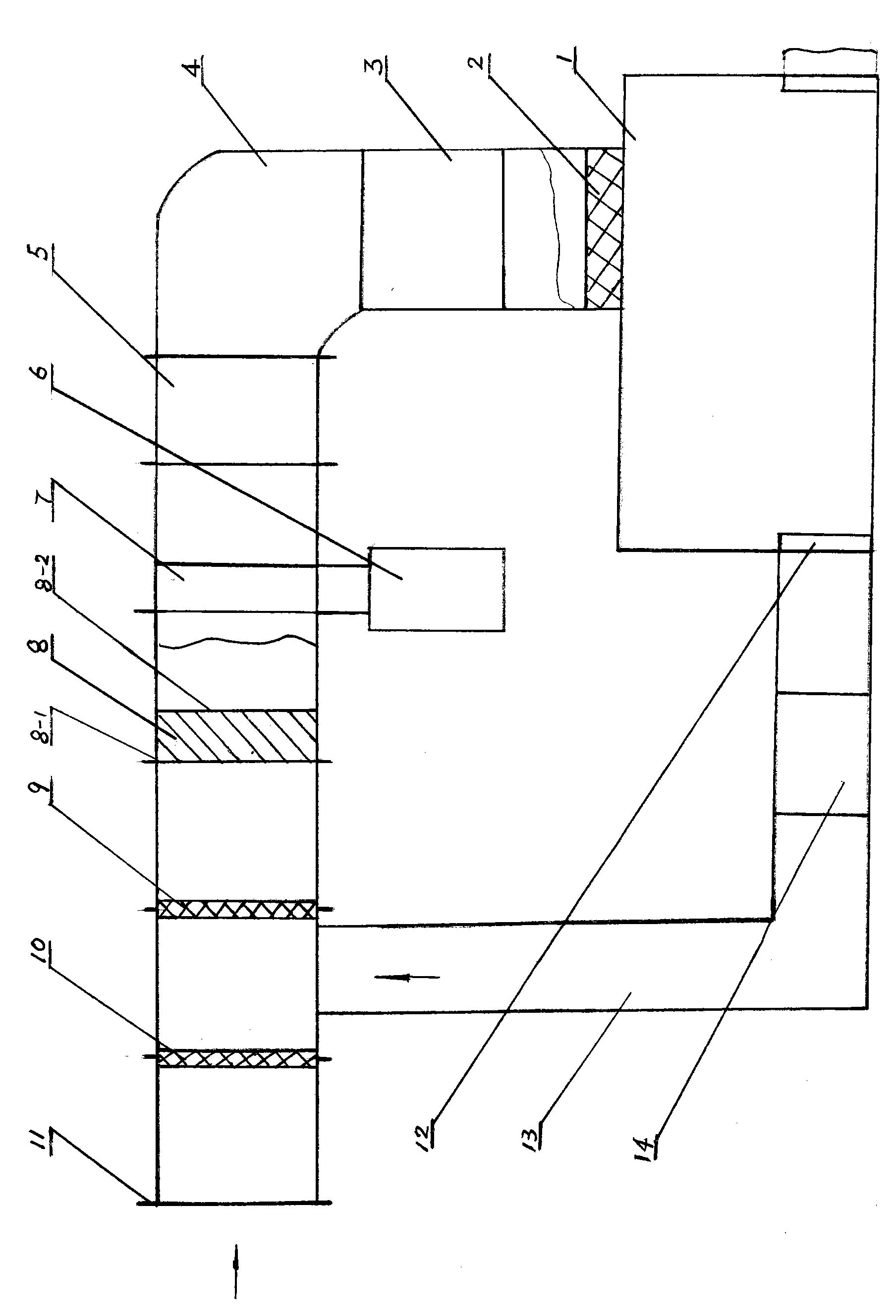

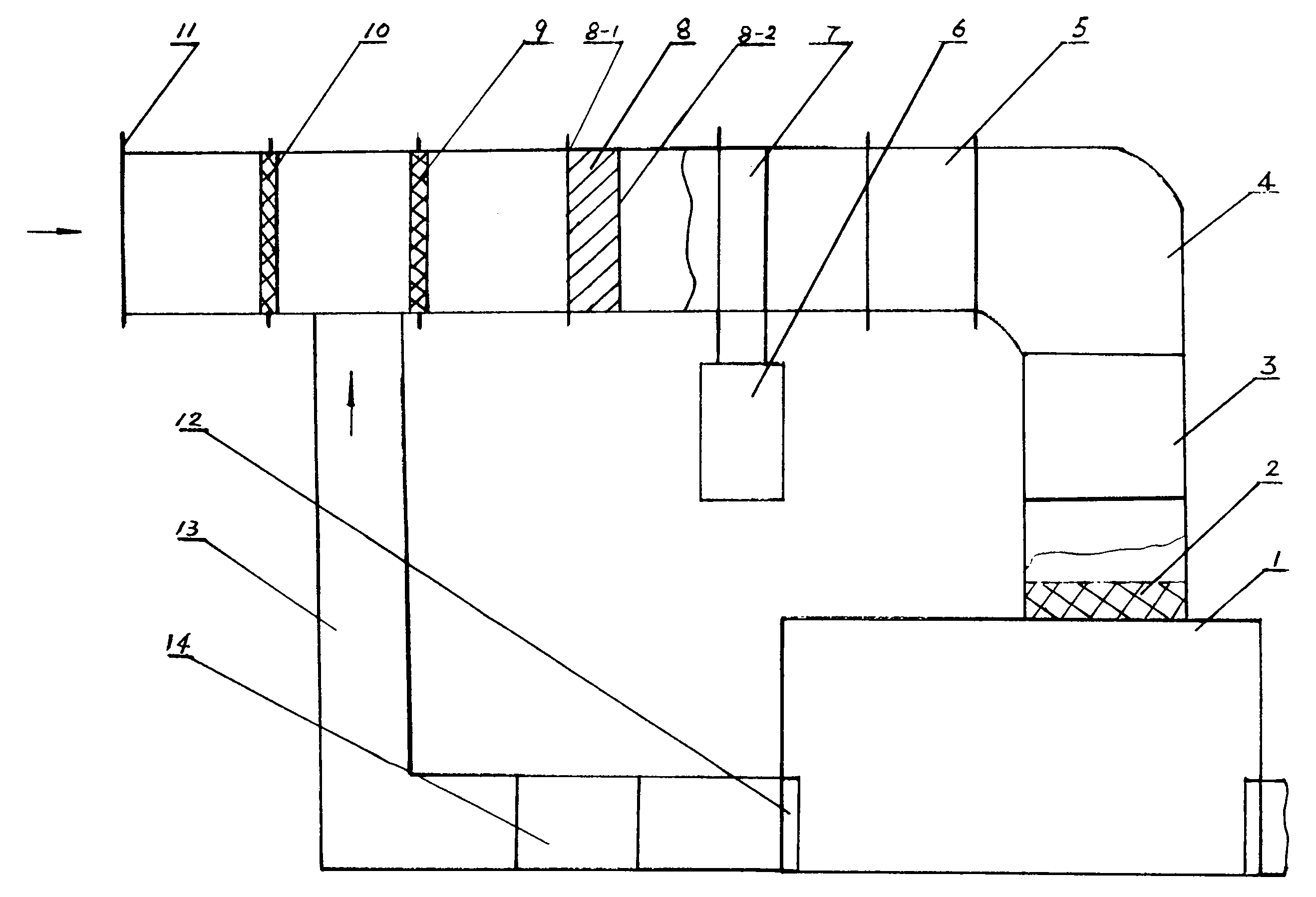

[0006] The present invention will be further described below in conjunction with accompanying drawing:

[0007] See attached figure 1 , the whole device passes through the connection flange (11) according to the initial effect filter (10), the medium effect filter (9), the plasma electric field (8), the cooling device (7), the blower fan (5), the muffler I (3) The order of the high efficiency filter (2) is fixedly connected into one to form the air duct (4); through the return air duct (13) fixed between the primary effect filter (10) and the medium effect filter (9) The connected muffler II (14) is connected to the return air outlet (12) provided on both sides of the clean room (1); the heat pump (6) is fixed at one end of the cooling device (7); the muffler I (3) and the muffler II (7) There are foamed aluminum plates fixed around the foamed aluminum plate, and a cross-shaped deflector is arranged in the cavity of the foamed aluminum plate to form four diversion channels. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com