Packaging structure and lead frame thereof

A technology of packaging structure and lead frame, which is applied in the direction of semiconductor devices, semiconductor/solid-state device parts, electrical components, etc., can solve the problems of reduced reliability of packaging structure, increased material cost, and unstable structure, etc., to increase lead strength, Low cost and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The package structure and its lead frame according to preferred embodiments of the present invention will be described below with reference to related drawings, wherein the same components will be described with the same symbols.

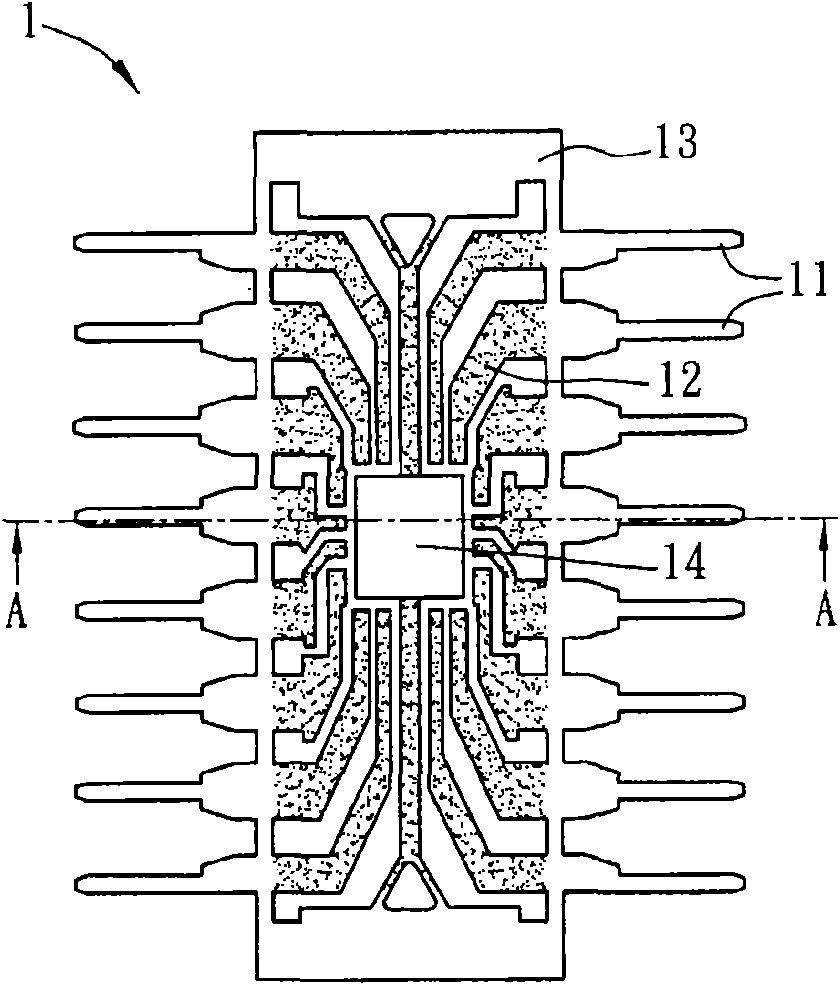

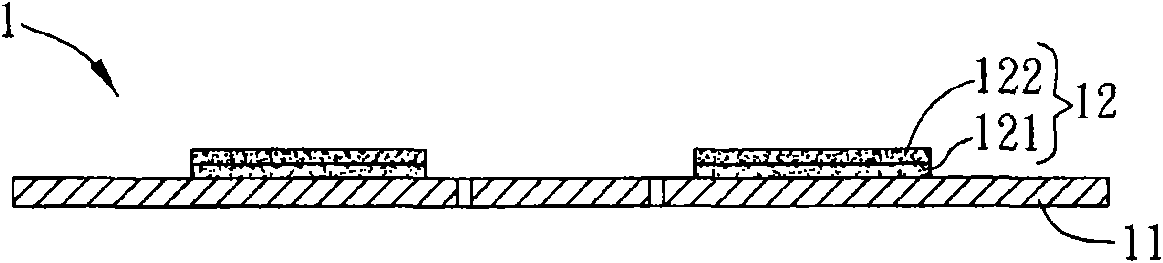

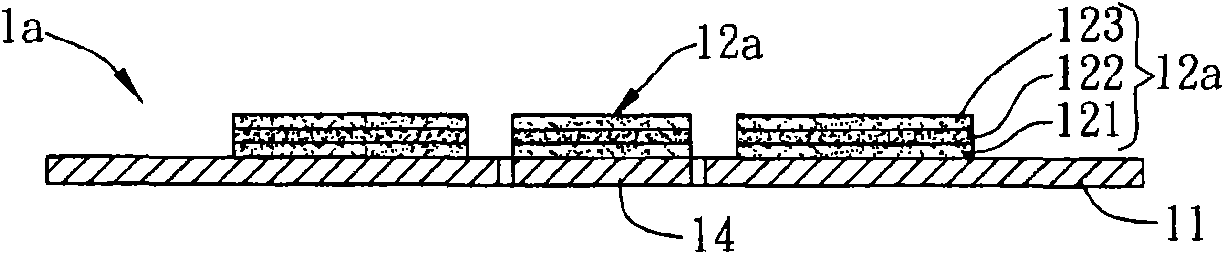

[0036] Please refer to Figure 1A and Figure 1B shown, where Figure 1A is a top view of the lead frame of the preferred embodiment of the present invention, Figure 1B is the lead frame edge Figure 1A The cross-section of the line A-A in the middle. It should be noted that in Figure 1B In the figure, for the sake of clarity, the relative proportions of the wires 11 and the metal composite layer 12 are not actual proportions.

[0037] The lead frame 1 of this embodiment can be applied in the packaging structure of light-emitting diodes, integrated circuits, or other electronic components. Here, one lead frame is taken as an example. It should be noted that in actual manufacturing, there may be multiple The lead frame is manufactured tog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com