Connector

A technology of connectors and connecting parts, which is applied in the direction of connection, fixed connection, contact parts, etc., can solve the problems of complex butt joint production process, low reliability, and peeling of metal layers, so as to improve processing and production process, enhance reliability, The effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

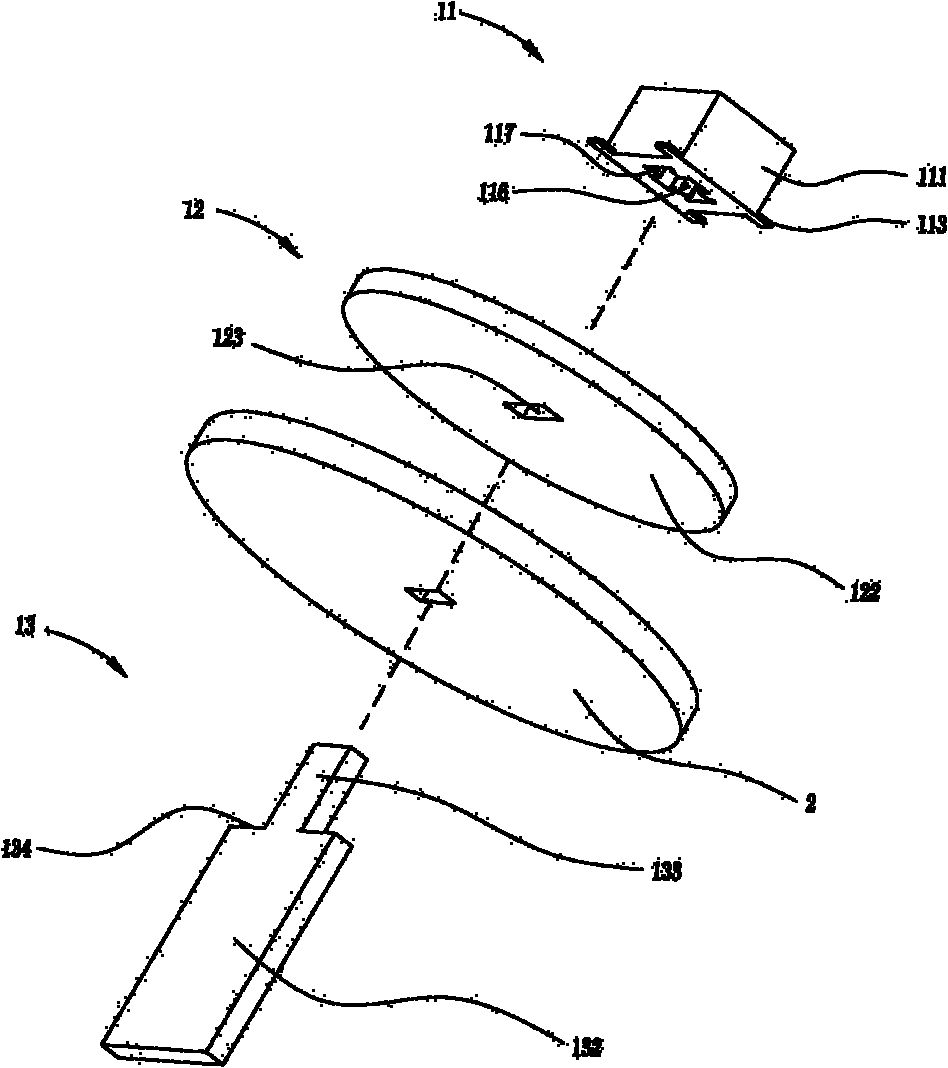

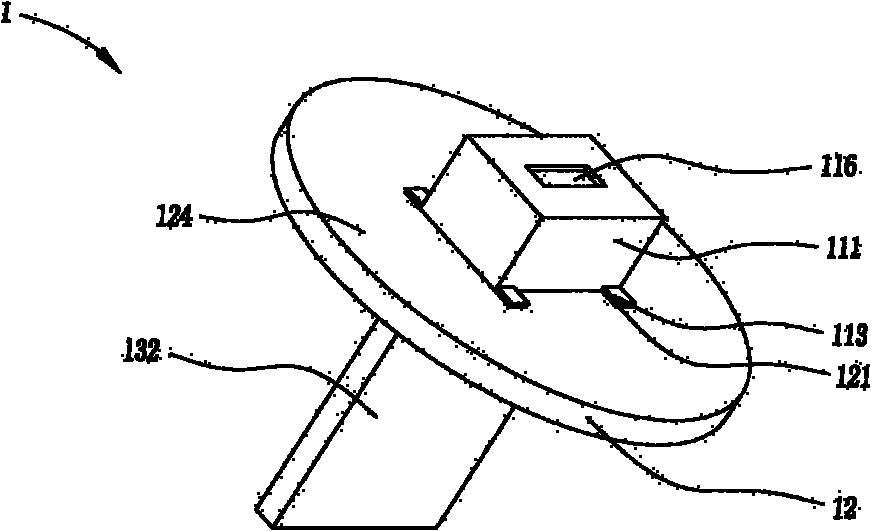

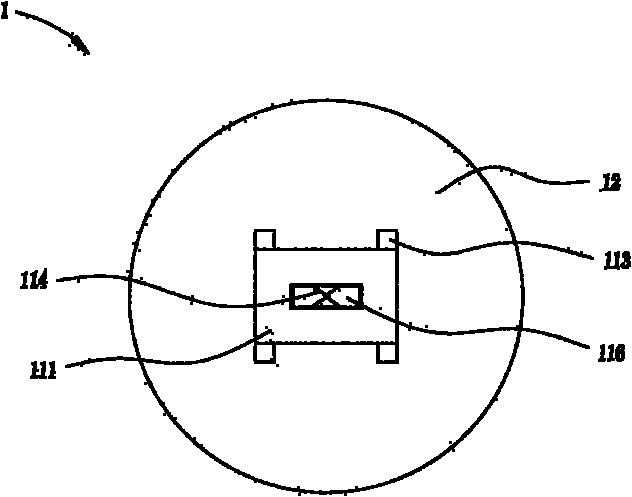

[0037] see Figure 1-Figure 3 , the embodiment of the present invention provides a connector 11 for connecting a mating substrate 12 and a rigid substrate 13, the connector 11 includes an insulating body 111, which accommodates at least one terminal 112, the terminal 112 and The docking substrate 12 is electrically connected, and at least one solder leg 113 corresponding to the terminal 12 is provided at the bottom of the insulating body 111 , and each solder leg 113 is welded on one side of the rigid substrate 13 In this way, the connector 11 is electrically connected to the rigid substrate 12 and the docking substrate 13, avoiding the connection between the substrates and the substrates in the prior art by soldering wires or connecting terminals to terminals, to a great extent It improves the processing and production process, saves time and labor; in addition, the connector 11 can be installed on any side of the rigid substrate 12, so that the design position of the connect...

no. 2 example

[0047] see Figure 7 As shown, the difference between the connector 11 of the present invention and the first embodiment is that: the connector 11 is provided with two terminals, and has two welding feet 113 welded on the rigid substrate 12 . Other structures are similar to those of the above-mentioned first embodiment, and will not be repeated here.

no. 3 example

[0049] see Figure 8 As shown, the difference between the connector 11 of the present invention and the first embodiment is that: the connector 11 is provided with three terminals, and has three welding feet 113 welded on the rigid substrate 12 . Other structures are similar to those of the above-mentioned first embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com