Method of flocculation

A technology for coagulation treatment and water treatment, which is applied in the direction of filtration treatment, separation method, flocculation/sedimentation water/sewage treatment, etc., and can solve the problems of reducing the amount of inorganic coagulant used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

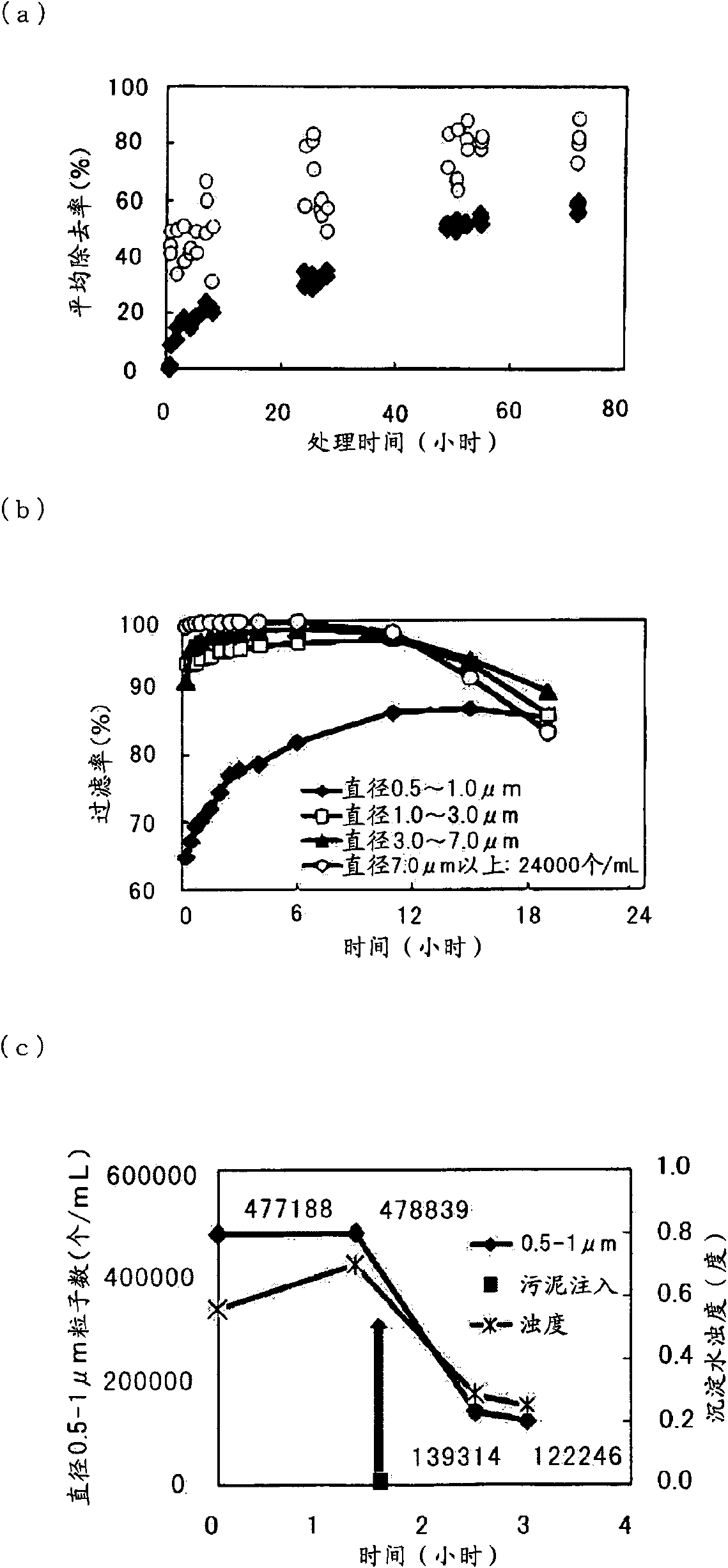

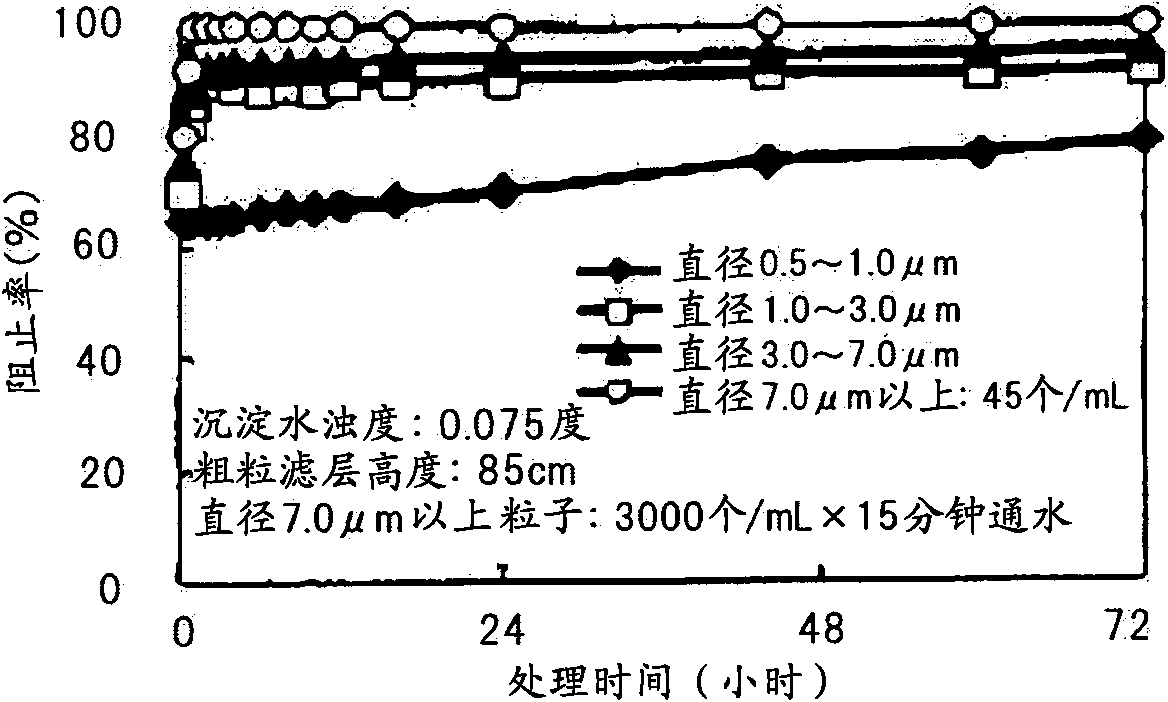

[0131] The feature of Example 1 is that in the contact material accumulation tank 12, the water 1 to be treated is made to flow from the lower side to the upper side.

[0132] As described above, when the water to be treated 1 is moved from the bottom to the top, the flocs collide or come into contact with the contact material, and the sedimentation phenomenon occurs in the same manner as in the sedimentation tank 21. Compared with the case of moving from the top to the bottom, the coarse filtration efficiency is improved.

[0133] The efficiency of such a rough filtration efficiency is nothing more than increasing the degree to which flocs having a particle size of 7.0 μm or more remain (filtered) in the contact material accumulation tank 12 , thereby increasing the overall filtration rate.

Embodiment 2

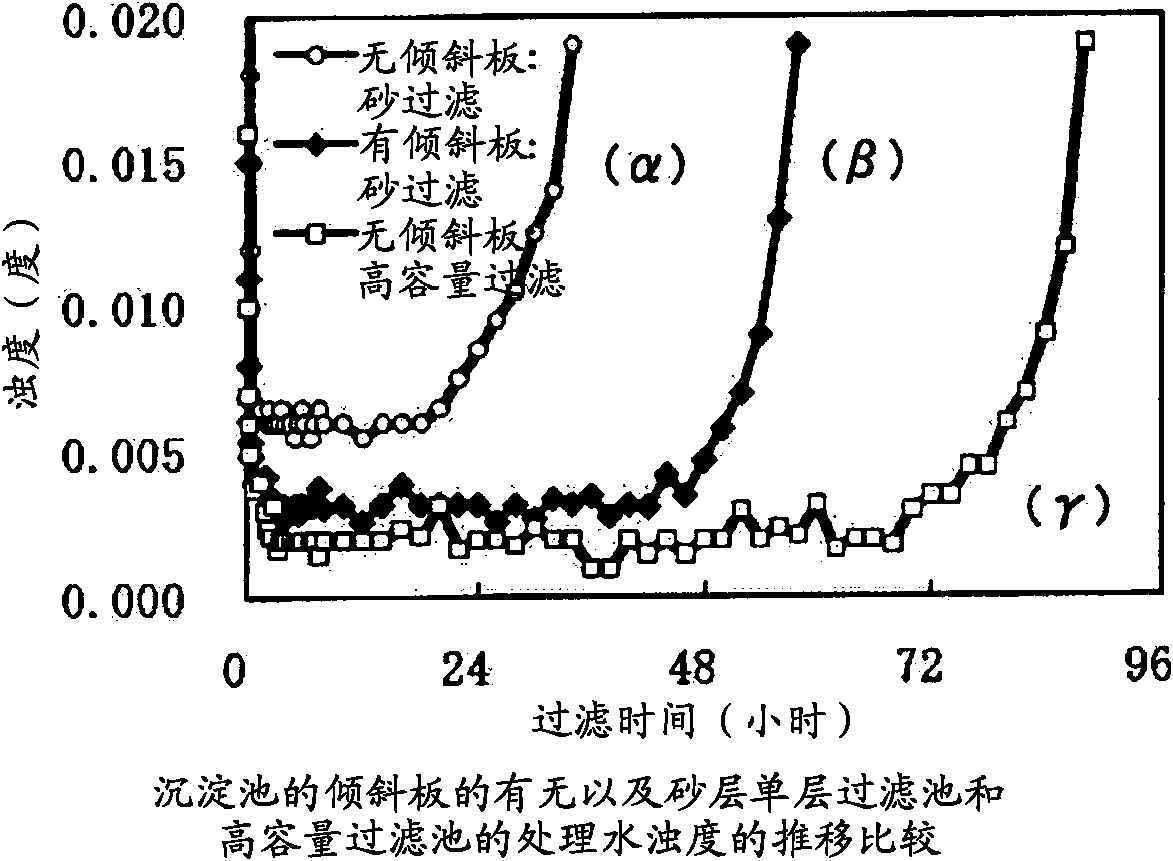

[0135] The feature of Example 2 is that a coagulant is injected again into the water to be treated 1 flowing out of the contact material accumulation tank 12 and flowing into the sand filter layer 14 .

[0136] As described above, when 0.5 mg / L or more of the flocculating agent is injected into the sand filter layer 14 again, flocculation of fine particles in the sand filter layer 14 occurs, and the filtration efficiency in the sand filter layer 14 is improved.

[0137] In particular, when the water to be treated 1 that has passed through the sand filter layer 14 is not used as purified water but as discharge water, flocs having a large particle size are also captured in the surface layer portion in the sand filter layer 14 in advance. As a result, purified water with low turbidity can be obtained, and in this case, re-injection of 0.5 mg / L or more of the flocculating agent promotes the effect of discharging water.

Embodiment 3

[0139] Embodiment 3 is characterized in that, as Image 6 As shown, the contact material accumulation tank 12 is filled with the upper limit of flocs containing flocs having a particle size of 7.0 μm or more, and the excess flocs are discharged from the discharge port 16 and closed at the inflow stage of the water to be treated 1 . The valve 15 of the discharge port 16 .

[0140] When the flocs containing flocs having a particle size of 7.0 μm or more are filled in the inlet of the contact material accumulation tank 12 and / or the vicinity of the above-mentioned inlet, the filling amount of the flocs naturally exists in an appropriate amount.

[0141] That is, when the filling amount is too large, the filtration rate of the micro-flocs and the flocs increases rapidly, but conversely, the residual (filtration) of the micro-flocs and the flocs in the contact material collecting tank 12 rapidly progresses Therefore, the time for which the contact material accumulation tank 12 tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com