Method for storing steam-flaked grain feed

A technology for steam tableting and grains, which is applied to the storage field of steam tableting grain feed, can solve the problems of destroying the nutritional value of tableted grains and the occurrence of mildew on tableted grains, reducing the rate of mildew and deterioration and improving the feed value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The grain steam tableting equipment introduced by Hebei Kate Feed Group Company from ROSKAMP Company of the United States is adopted. The corn is conditioned by high-temperature steam at 98-105°C for 30-60 minutes in a steam tablet machine, rolled into thin slices of 0.8-1.5mm, and then cooled to below 37°C.

Embodiment 2

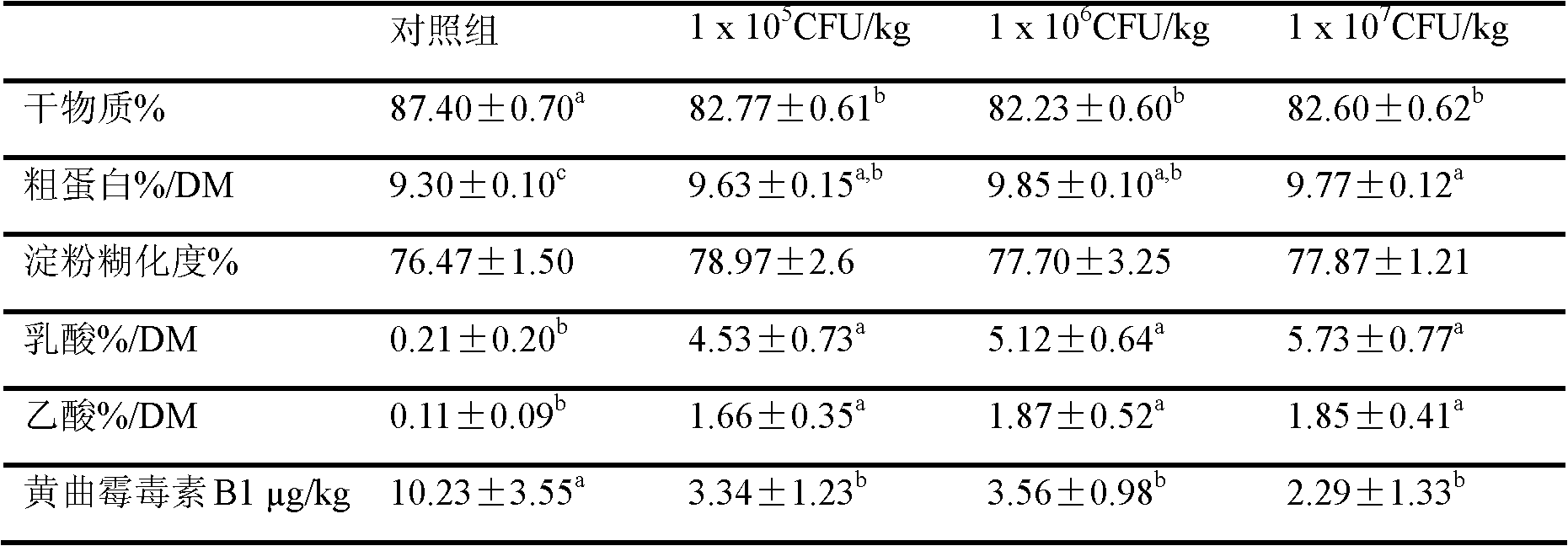

[0018] The grain steam tableting equipment introduced by Hebei Kate Feed Group Company from ROSKAMP Company of the United States is adopted. The corn is first prepared in a steam tablet machine by high-temperature steam at 98-105°C for 30-60 minutes, rolled into thin slices of 0.8-1.5mm, cooled to below 37°C, and then mixed with 1x10 5 The mixed lactobacillus starter of CFU / kg flaked corn is finally compacted by a compression feed baler, bundled and sealed, and stored by anaerobic fermentation.

[0019] The steam-flaked fermented and stored corn is mixed with 16.03% cottonseed meal, 0.17% baking soda, 0.23% salt, 0.29% stone powder, 1.21% additives, 25.80% whole plant corn silage, and 23.36% corn stalks at a ratio of 32.9% to form a complete mixing day Compared with the control ration (the only difference between the total mixed ration in this embodiment is that it adds ordinary steam-pressed corn), the feed intake of the beef cattle increased by 8.36%, and the daily gain Inc...

Embodiment 3

[0021] The grain steam tableting equipment introduced by Hebei Kate Feed Group Company from ROSKAMP Company of the United States is adopted. The corn is first prepared in a steam tablet machine by high-temperature steam at 98-105°C for 30-60 minutes, rolled into thin slices of 0.8-1.5mm, cooled to below 37°C, and then mixed with 1x10 6 The mixed lactobacillus starter of CFU / kg flaked corn is finally compacted by a compression feed baler, bundled and sealed, and stored by anaerobic fermentation.

[0022] Steam flaked corn was mixed with 16.03% cottonseed meal, 0.17% baking soda, 0.23% salt, 0.29% stone powder, 1.21% additives, 25.80% whole plant corn silage, and 23.36% corn stalks to form a complete mixed diet at a ratio of 32.9%. When feeding beef cattle, compared with the control diet (the only difference from the total mixed diet of this embodiment is that ordinary steam-pressed corn is added), after feeding, the feed intake of beef cattle increased by 8.51%, and the daily g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com