Die for S-shaped bending of copper bars

A mold and flat bending technology, which is applied in the field of molds for bending copper bars into S shapes, to achieve the effects of high processing precision, fast processing, and easy withdrawal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

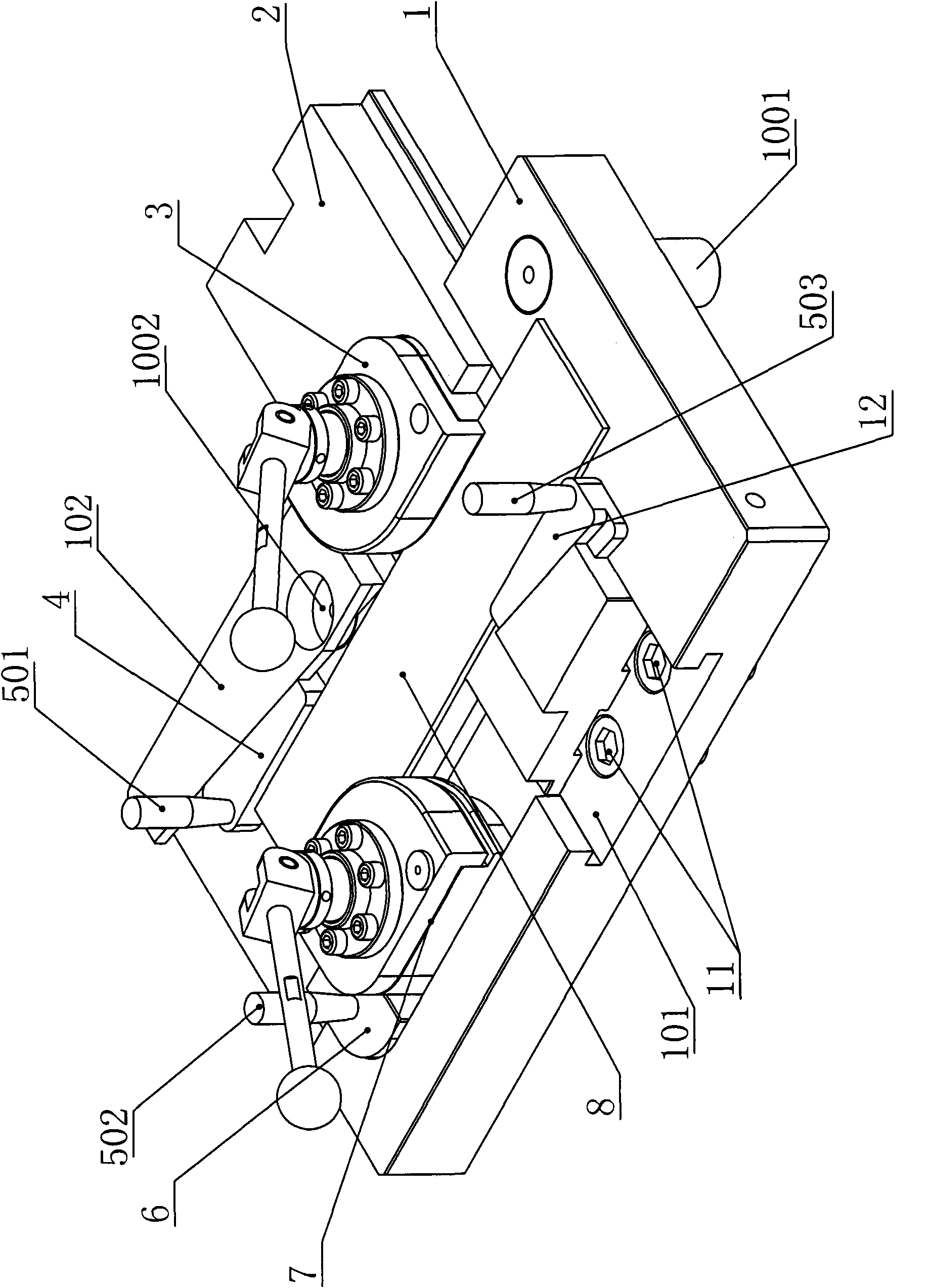

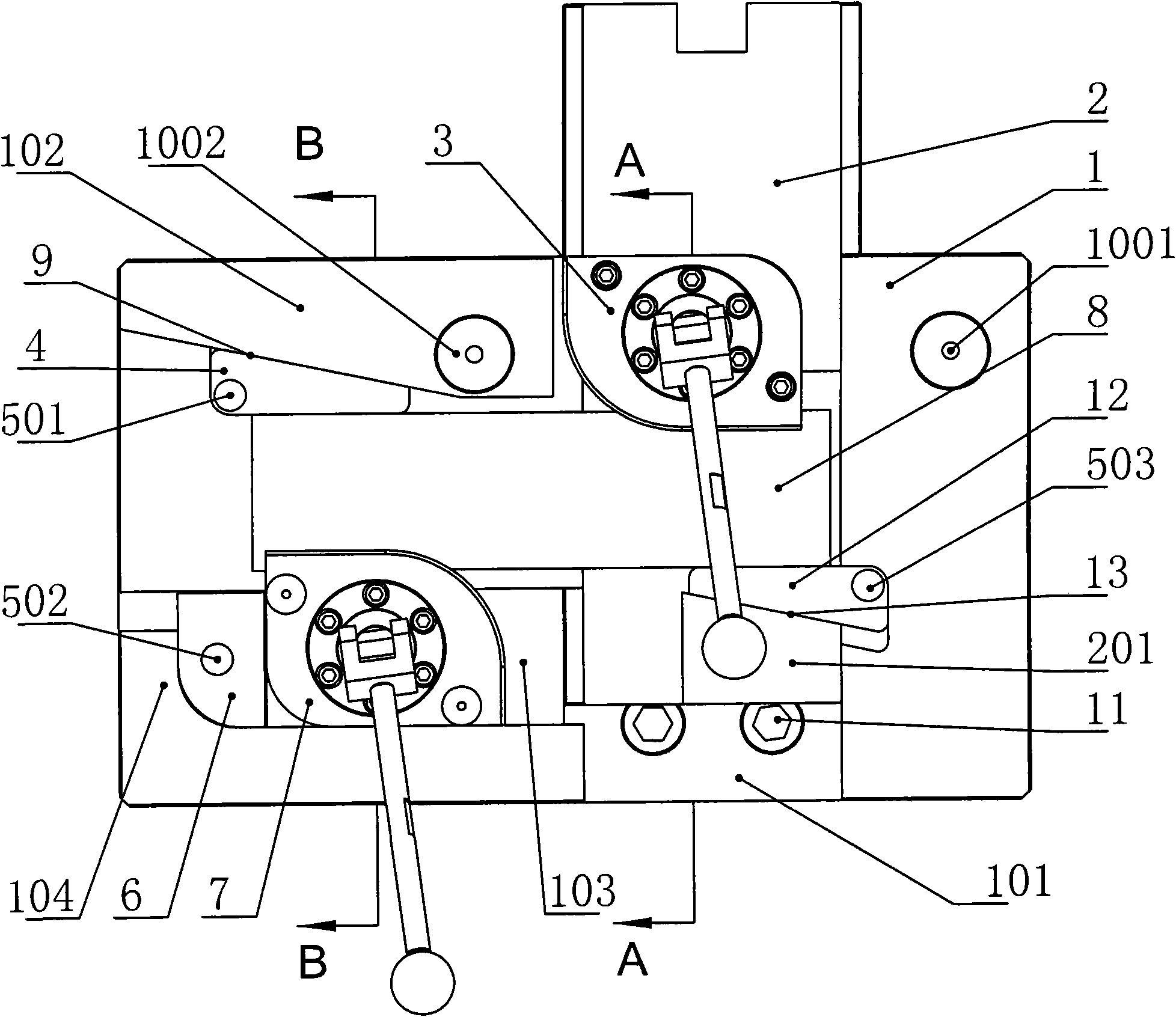

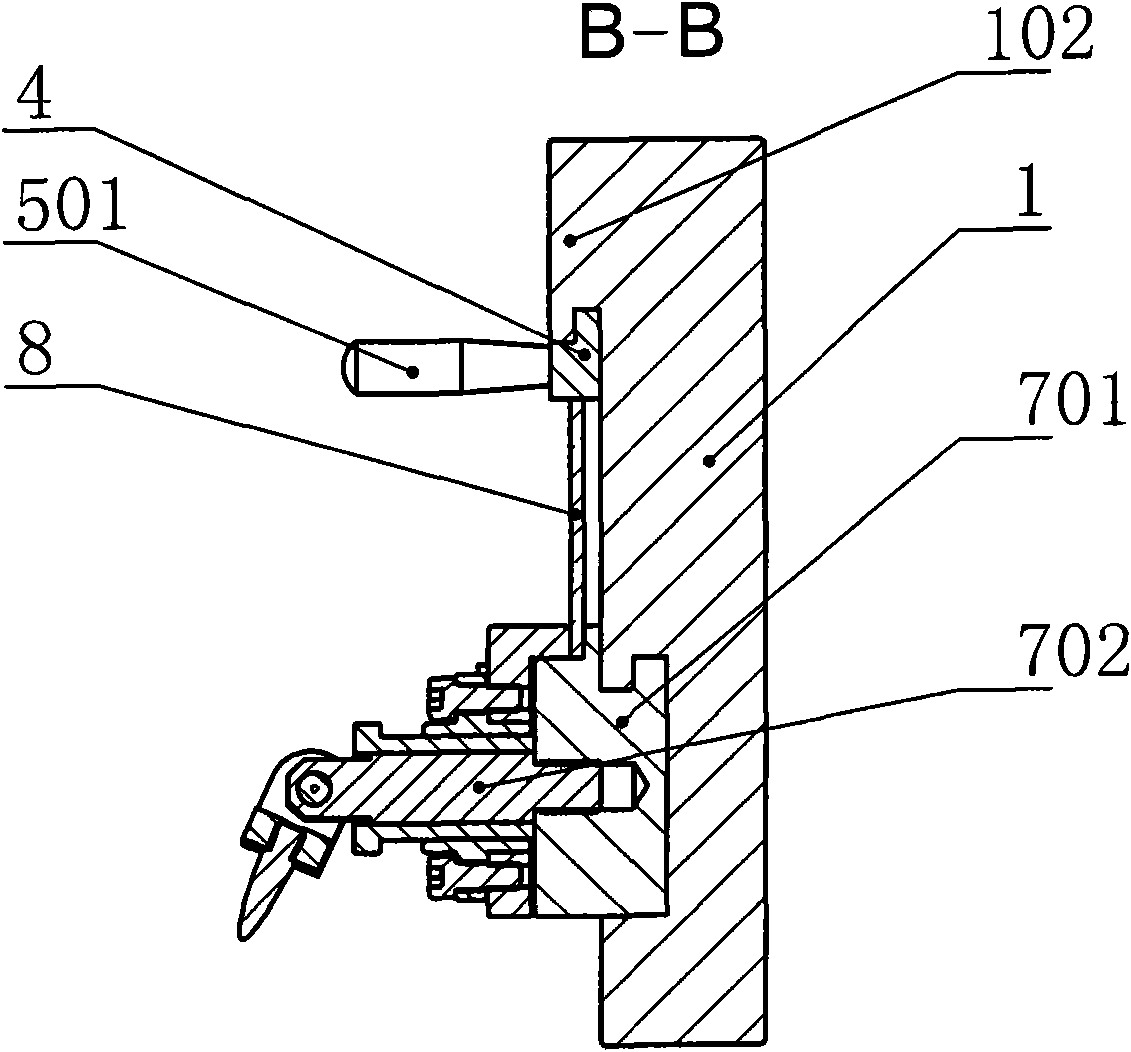

[0018] Such as Figure 1-5 As shown, it is a mold for S-shaped bending of copper bars, and a first chute 101 is provided in the front and rear direction of the pallet 1, and the first chute 101 runs through from the front side of the pallet 1 to the rear side of the pallet 1. In the first chute 101, a support plate 2 is arranged, and the support plate 2 can slide back and forth along the first chute 101; the support plate 2 is fixed with the first flat bending die 3 with screws; 101 is vertically provided with a second chute 103, the second flat bending die 7 is arranged in the second chute 103, one end of the second chute 103 is connected with the first chute 101, and the supporting plate 1 is connected with the second chute 103 The other end of the corresponding end is provided with a limiter 104; a backing plate 6 is provided between the limiter 104 and the second flat bending die 7; when the second flat bending die 7 is installed in the second chute 103, it is located On ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com