Method for detecting and controlling free loops by thin-strip continuous casting

A control method and looper technology, which are applied in the field of free looper detection and control in thin strip continuous casting, can solve the problems of complex strip deformation, high protection requirements for measuring devices, uncertain free looper effect, etc., and achieve good stability. , The adjustment method is direct and reliable, and the effect of avoiding cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below by embodiment.

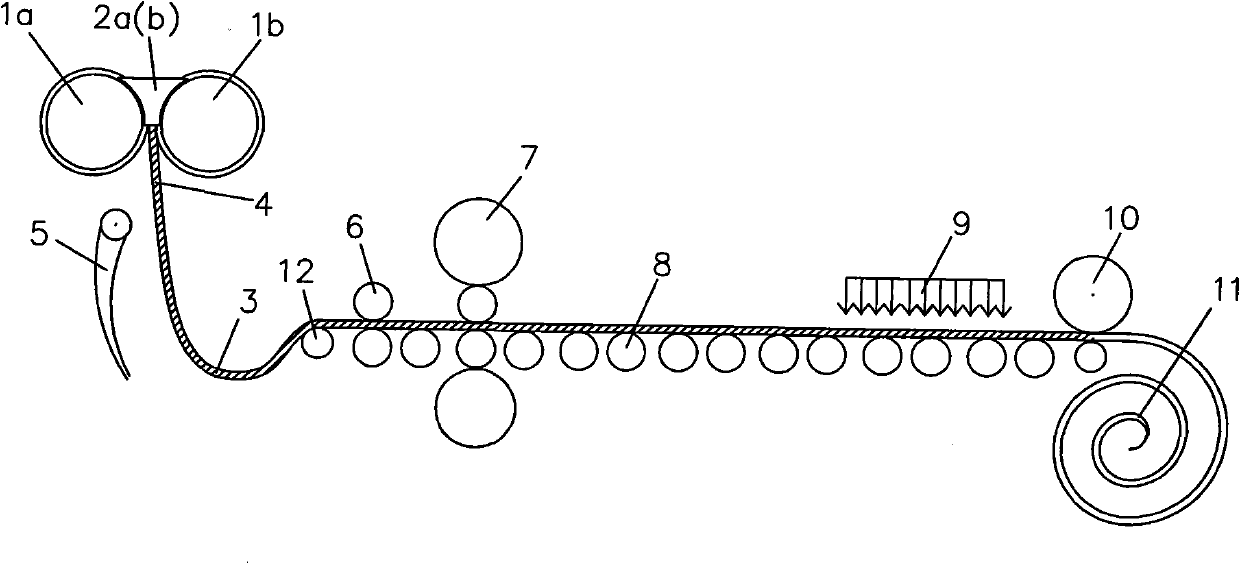

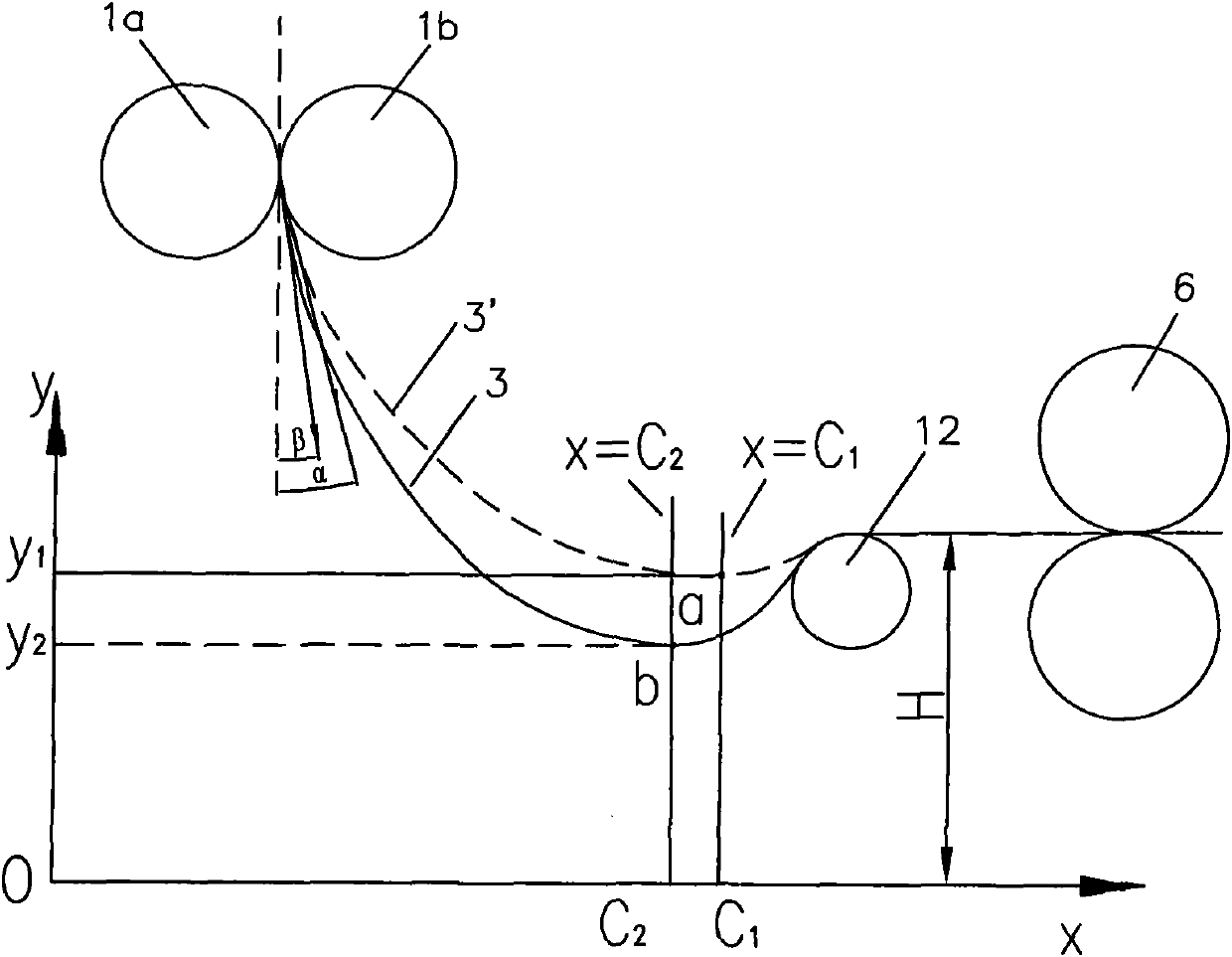

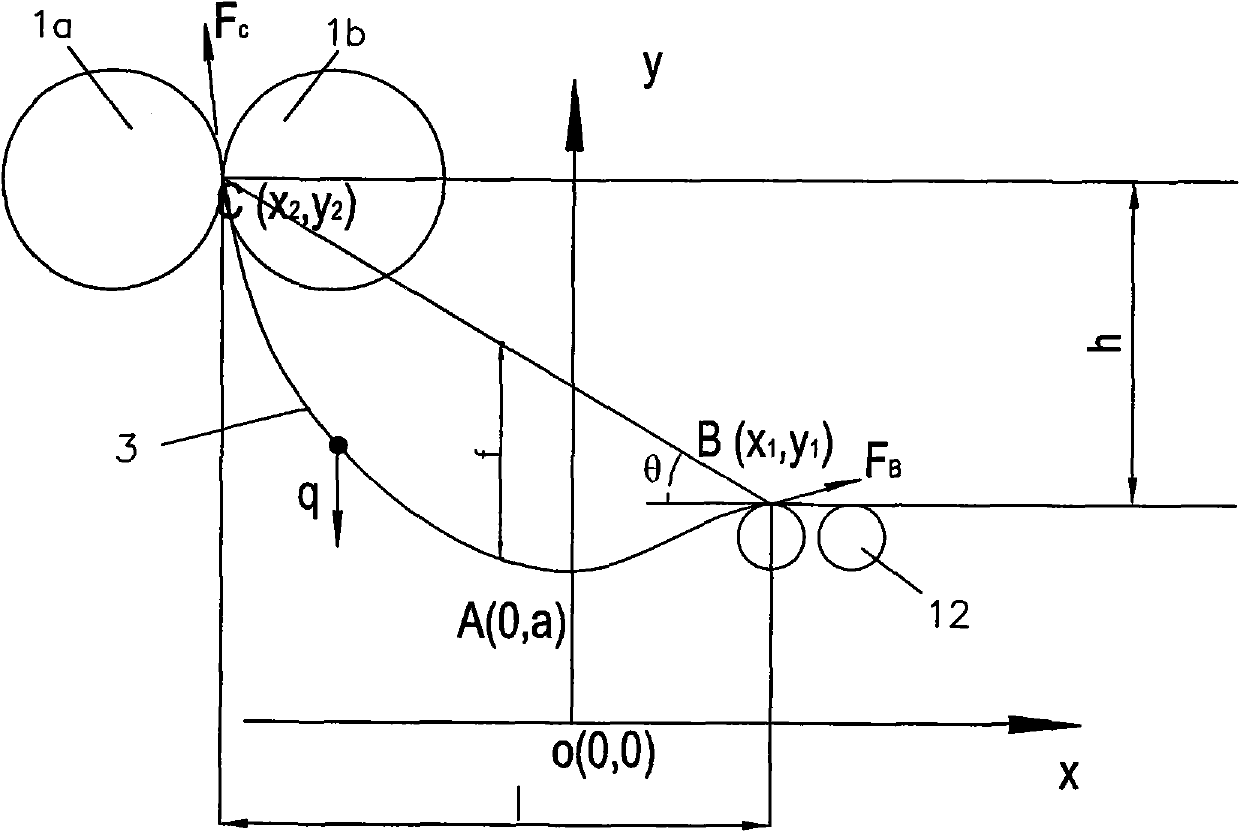

[0051] see Figure 1 to Figure 5 , similar to the typical thin strip continuous casting process, in this example, it includes two relatively rotating cooling rolls 1a, 1b and side sealing plates 2a, 2b capable of rapid cooling, looper guide rolls 12, and a device for adjusting the position of the looper guide rolls Oil cylinders 13, 14 and pinch rollers 6 form loopers 3, 3' between looper guide rollers 12 and cooling rollers 1a, 1b. Since the position of the cooling roll is higher than that of the looper guide roll, the looper formed between the two is of unequal height. Oil cylinders 13, 14 can make the left and right bearing seats of the looper guide rollers move forward and backward synchronously along the advancing direction of the casting band.

[0052] In the loop detection and control system in this embodiment, include: loop detection value processor 15, comparator 16, main controller 17, fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com