Energy-saving electric iron base

A technology of electric soldering iron and soldering iron holder, which is applied in auxiliary devices, metal processing equipment, manufacturing tools, etc., can solve the problems of easy burnout of electric soldering iron and waste of electric energy, achieve fast and convenient power failure, solve infinite heating, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

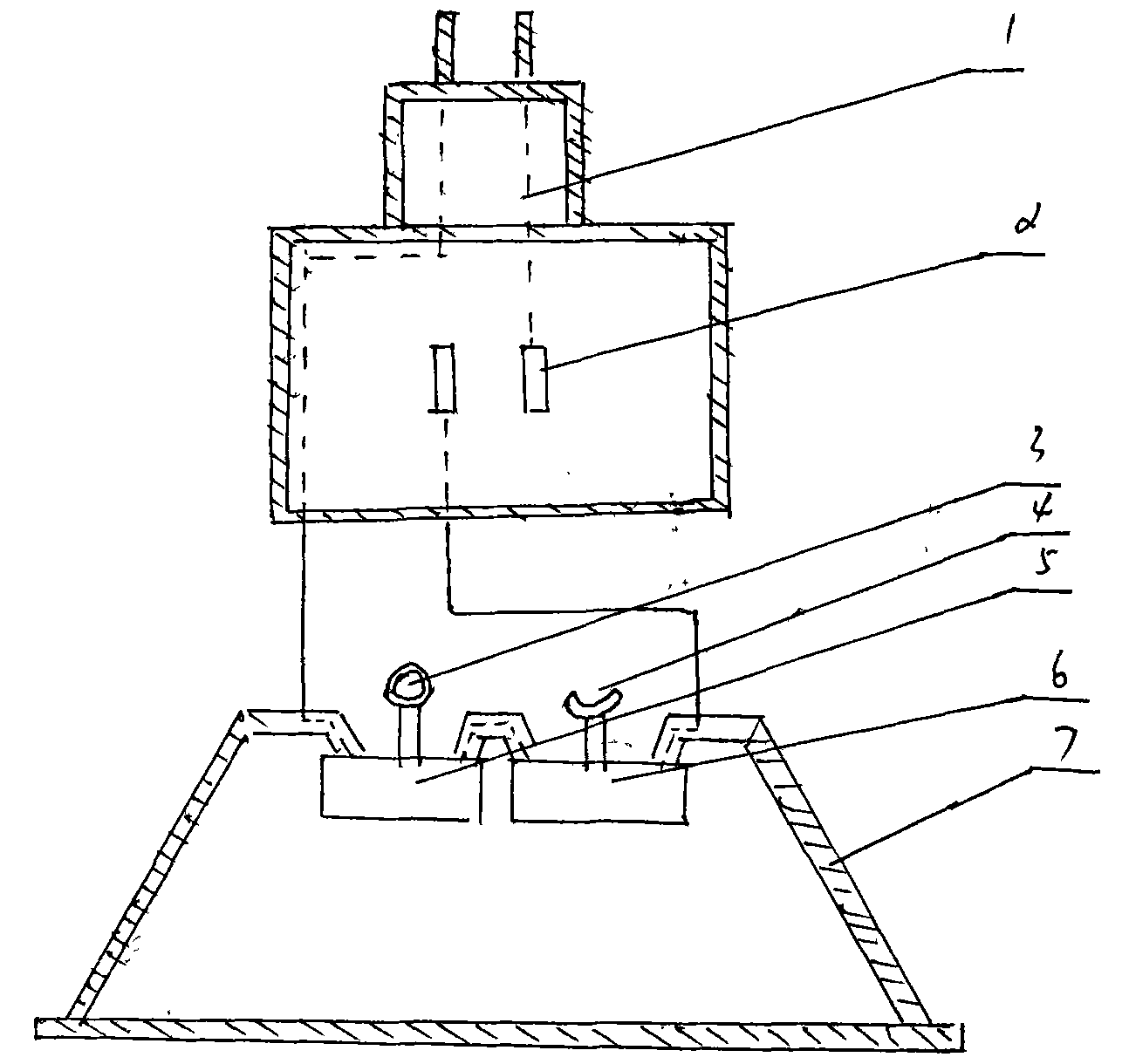

[0010] Such as figure 1 As shown, the present invention includes a power cord, a plug 1 connected to an energy-saving electric soldering iron base 2, and the electric soldering iron socket 2 is controlled in series by a temperature controller 5 and a push-down elastic switch 6; When the temperature controller 5 is turned on, the electric soldering iron socket 2 is powered on; when the temperature at 3 is higher than the required temperature, the thermostat 5 is off, and the electric soldering iron socket 2 is powered off; when the electric soldering iron is temporarily disabled , the electric soldering iron heating rod is pressed on the push-down elastic switch support 4, the switch 6 is closed, and the electric soldering iron socket 2 is powered off, so that the effect of automatic power-off and energy saving on demand is conveniently and quickly played.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com