Alkali-free oil displacement agent containing double long-chain s-triazine type ampholytic surfactant

A surfactant, s-triazine technology, applied in the field of alkali-free oil displacement agent, can solve problems such as oil displacement agent loss, achieve the effects of avoiding damage, being beneficial to sustainable development, and overcoming the decline of oil displacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] ① Preparation of oil displacement agent components

[0035] The surfactant was prepared into a 1% (mass percentage) mother solution with water under the above-mentioned measurement conditions. The single oil-displacing agent component is directly taken out from the mother liquor and prepared into solutions with different contents; the test solution of the compound oil-displacing agent component is prepared from the respective mother liquors according to the total content of the surfactant and the compounding ratio. Take out the required corresponding amount and mix, and dilute to the required concentration;

[0036] ② Determination

[0037] Turn on the spinning drop interfacial tensiometer and the computer, and preheat the spinning drop interfacial tensiometer to the measurement temperature. The solution to be tested was kept at the measuring temperature. Draw out the solution to be tested with a syringe, and rinse the centrifuge tube 4 to 5 times. After filling the...

Embodiment 1

[0039] 1) Alkali-free oil flooding formulation of double long-chain s-triazine amphoteric surfactants, the components are as follows, all in mass percent:

[0040] Sodium N-methyl-N-(4-dodecylamino-6-octylamino-1,3,5-s-triazin-2-yl)-2-aminoethanesulfonate 0.05% ~ 1.00%

[0041] Prepare mineralized water balance

[0042]2), test conditions: determination conditions 1

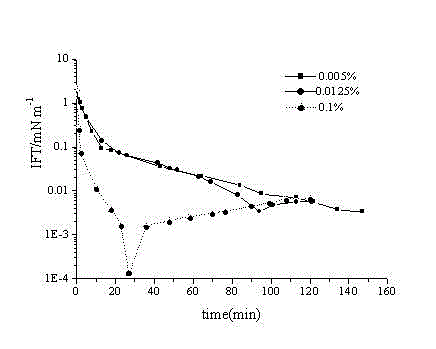

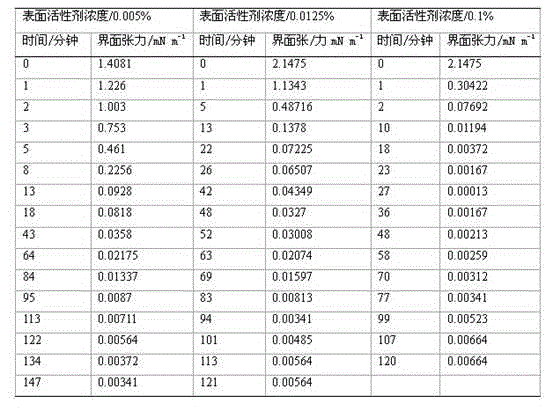

[0043] 3) Interfacial tension results with crude oil.

[0044]

Embodiment 2

[0046] 1) Alkali-free oil flooding formulation of double long-chain s-triazine amphoteric surfactants, the components are as follows, all in mass percent:

[0047] Sodium N-methyl-N-(4-decylamino-6-octylamino-1,3,5-s-triazin-2-yl)-2-aminoethanesulfonate 0.0125% ~ 1.0000%

[0048] Prepare mineralized water balance

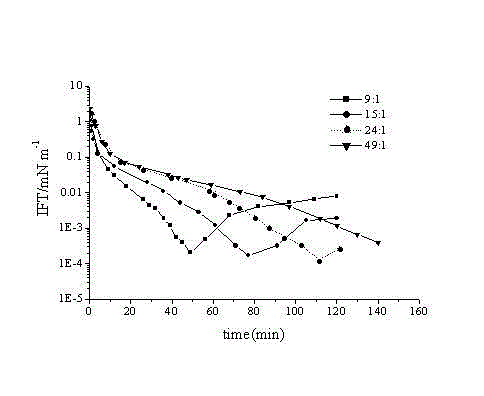

[0049] 2), test conditions: test conditions 1

[0050] 3) Interfacial tension results with crude oil.

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com