Device and method for correcting coke oven door knife edge

A furnace door knife edge and correction device technology, which is applied to the heating of coke ovens, doors/closures of coke ovens, coke ovens, etc., can solve the problems of high labor intensity, hammering maintenance, and calibration difficulties for operators in furnace door repair stations. , coke oven door knife inconvenience and other problems, to improve the calibration efficiency, eliminate smoke, improve the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

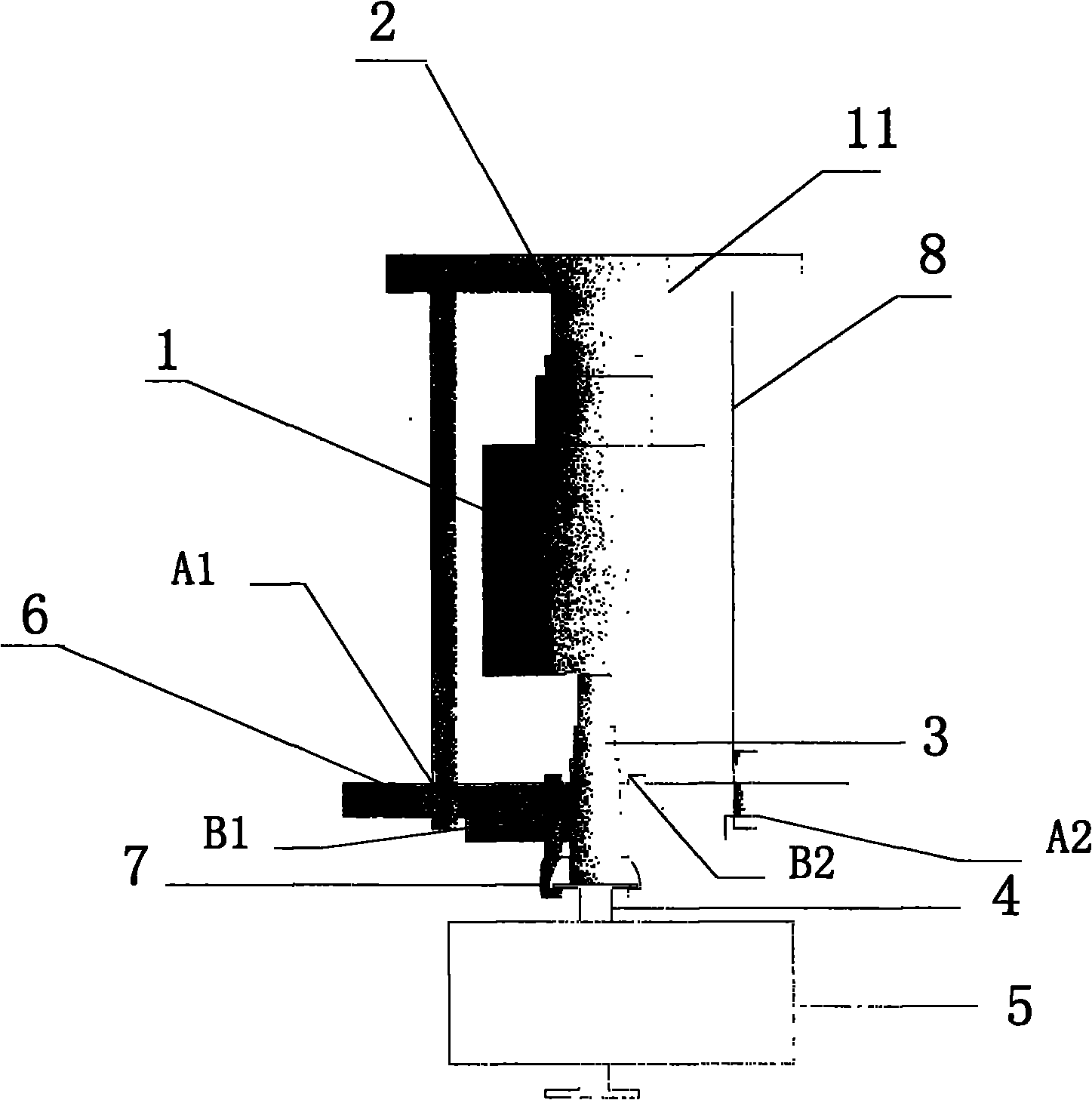

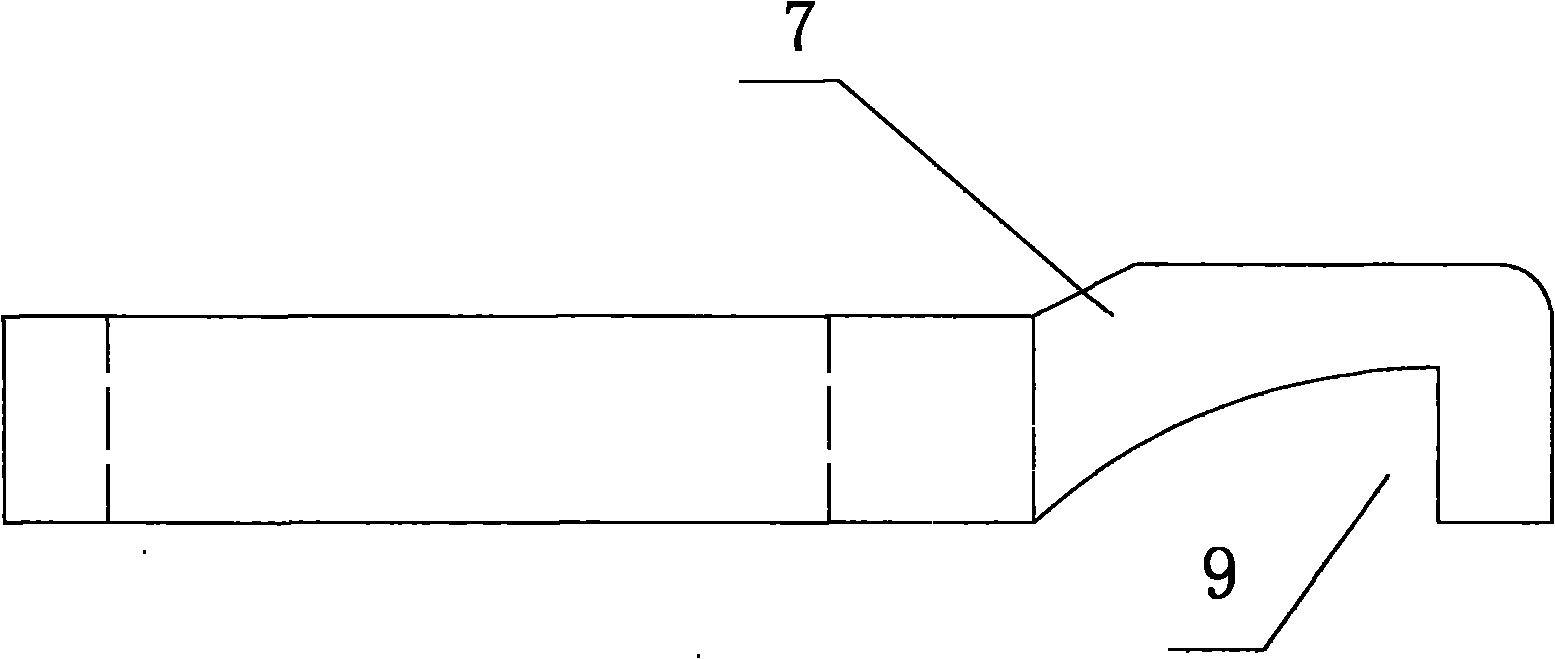

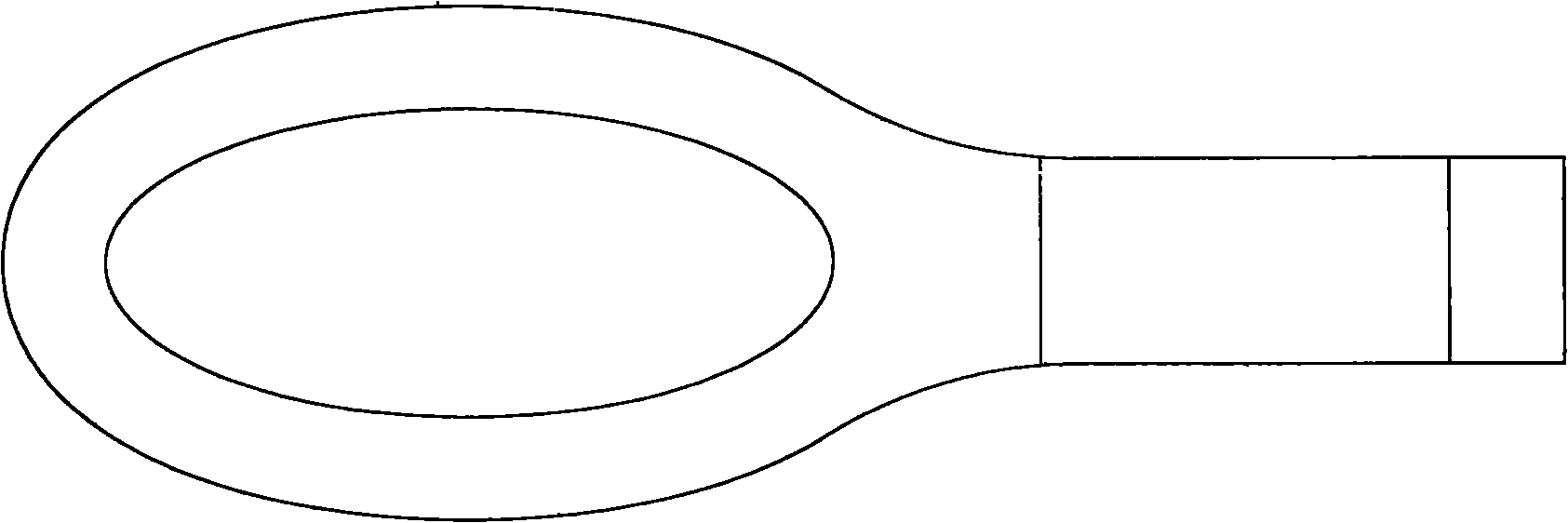

[0029] see now figure 1 , figure 1 It is a schematic diagram of an embodiment of the correction device for the knife edge of the coke oven door of the present invention. As shown in the figure, it is composed of an upper beam 11, two side beams 8, a lower beam 6 and two suspension hooks 7. The top ends of the two side beams 8 are connected with the upper beam 11 by solid welding, and The bottom ends of the beams 8 are respectively welded with an oval hole (A1, A2). The semi-major axis of the oval hole (A1, A2) is 35mm, and the semi-minor axis is 15mm (such as image 3 shown), one end of the two hanging hooks 7 is respectively welded with an oval hole (B1, B2), and the hanging hook 7 is movably suspended on the lower beam 6 through the oval hole (B1, B2). In the middle of the middle part, the semi-major axis of the oval holes (B1, B2) at one end of the two...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com