A measuring device for measuring the position of the mounting hole of the thrust reverser support

A measuring device and assembly hole technology, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problem that the support cannot quickly detect the position of the assembly hole, etc., and achieves high calibration work efficiency, simple calibration process, The effect of short verification cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

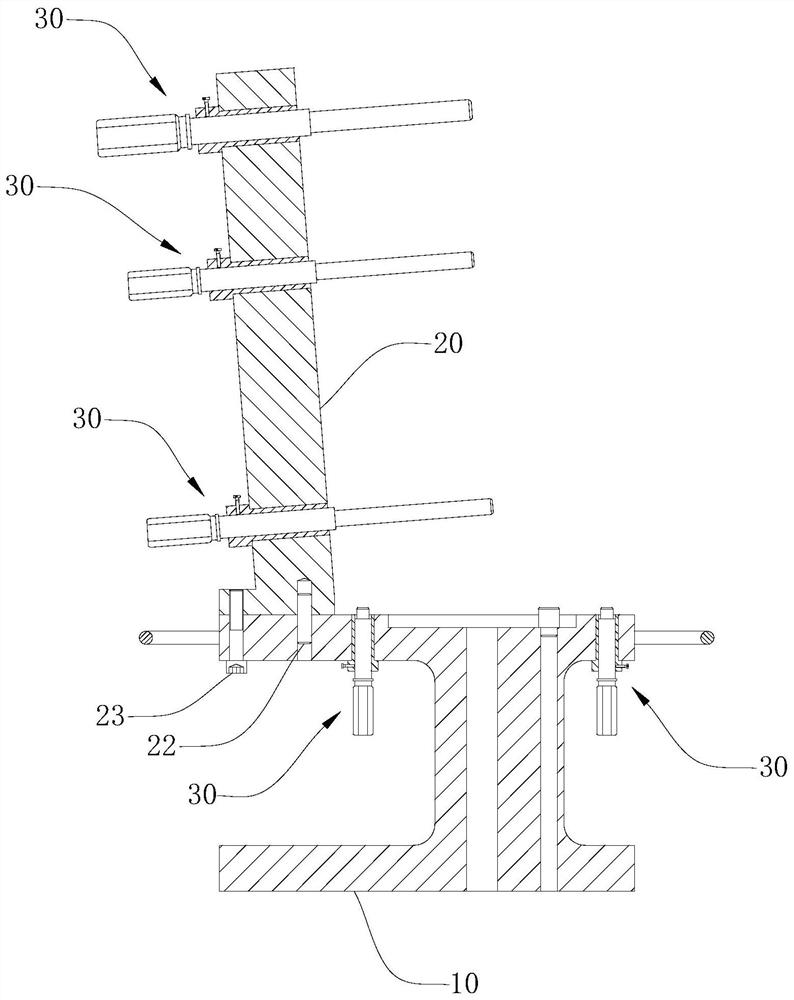

[0035] Please refer to figure 1 A measuring device that measures the position of the inversion of the anti-push device holder, including the base 10 and the support seat 20. The base 10 is used to secure the support 40 of the inversion device. The bottom of the support seat 20 is attached to the edge of the base 10 through the second positioning pin 22 and the bolt 23, and the support base 20 is inclined from the outer edge of the base 10 to the middle direction to match the tilt state of the support 40.

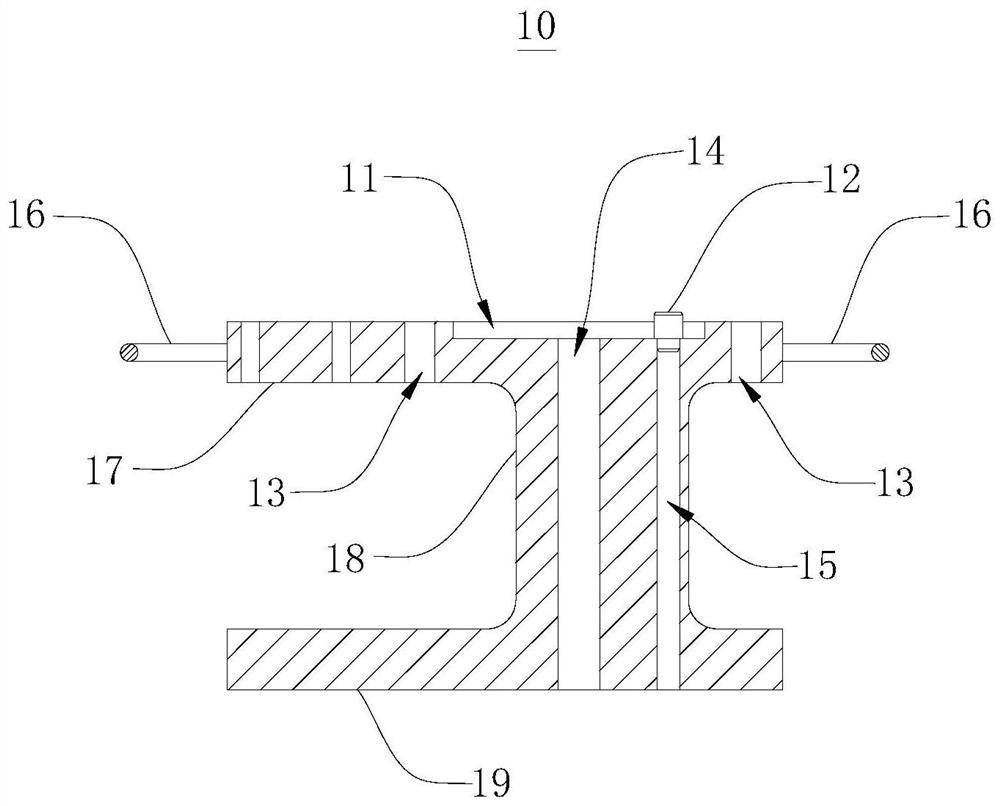

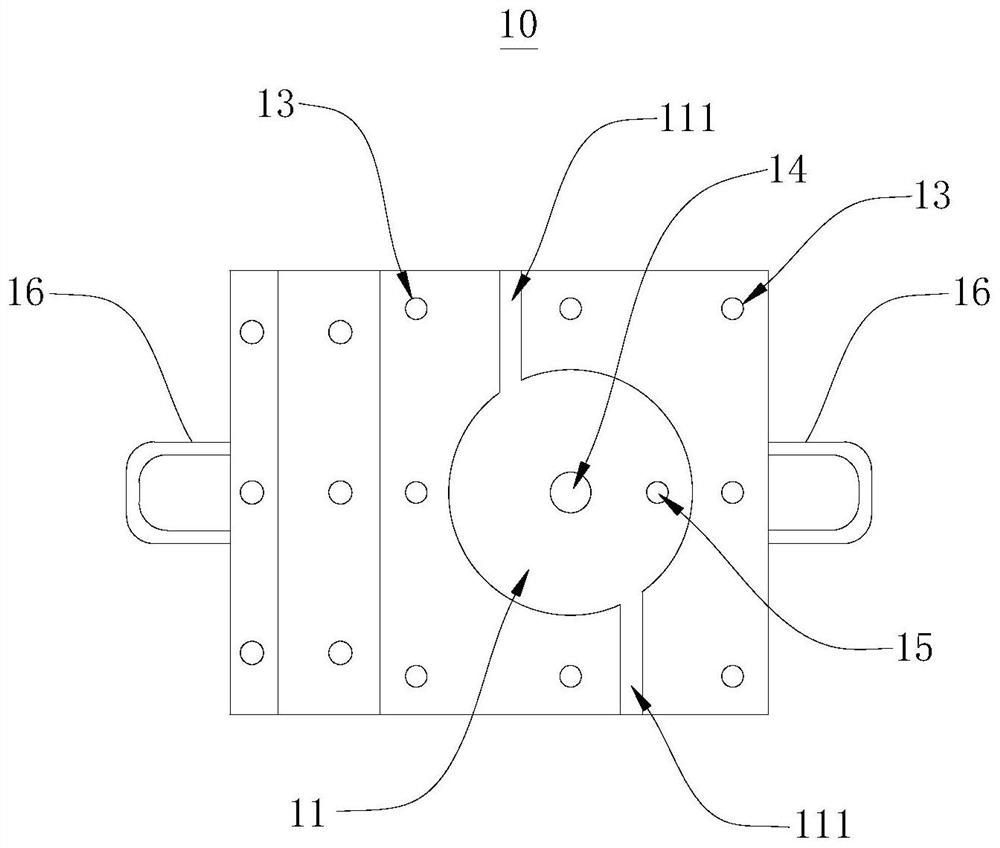

[0036] Please refer to figure 2 and image 3 The base 10 is in a honesty, which includes an upper support block 17, a connecting block 18, and a lower support block 19 connected from top to bottom. The top portion of the upper support block 17 is provided with a limit bit slot 11 and a through groove 111. The restricted groove 11 is circular, and the size is fitted with the bottom portion of the holder 40, and the limit slot 11 corresponds to the connection block 18 in the vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com