Mine safety production inspection system

A patrol inspection system and coal mine safety technology, applied in the transmission system, mining equipment, mining equipment, etc., can solve the problem that it is difficult for the management to determine the responsibility, and achieve the effect of strengthening security precautions, improving efficiency, and scientific management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

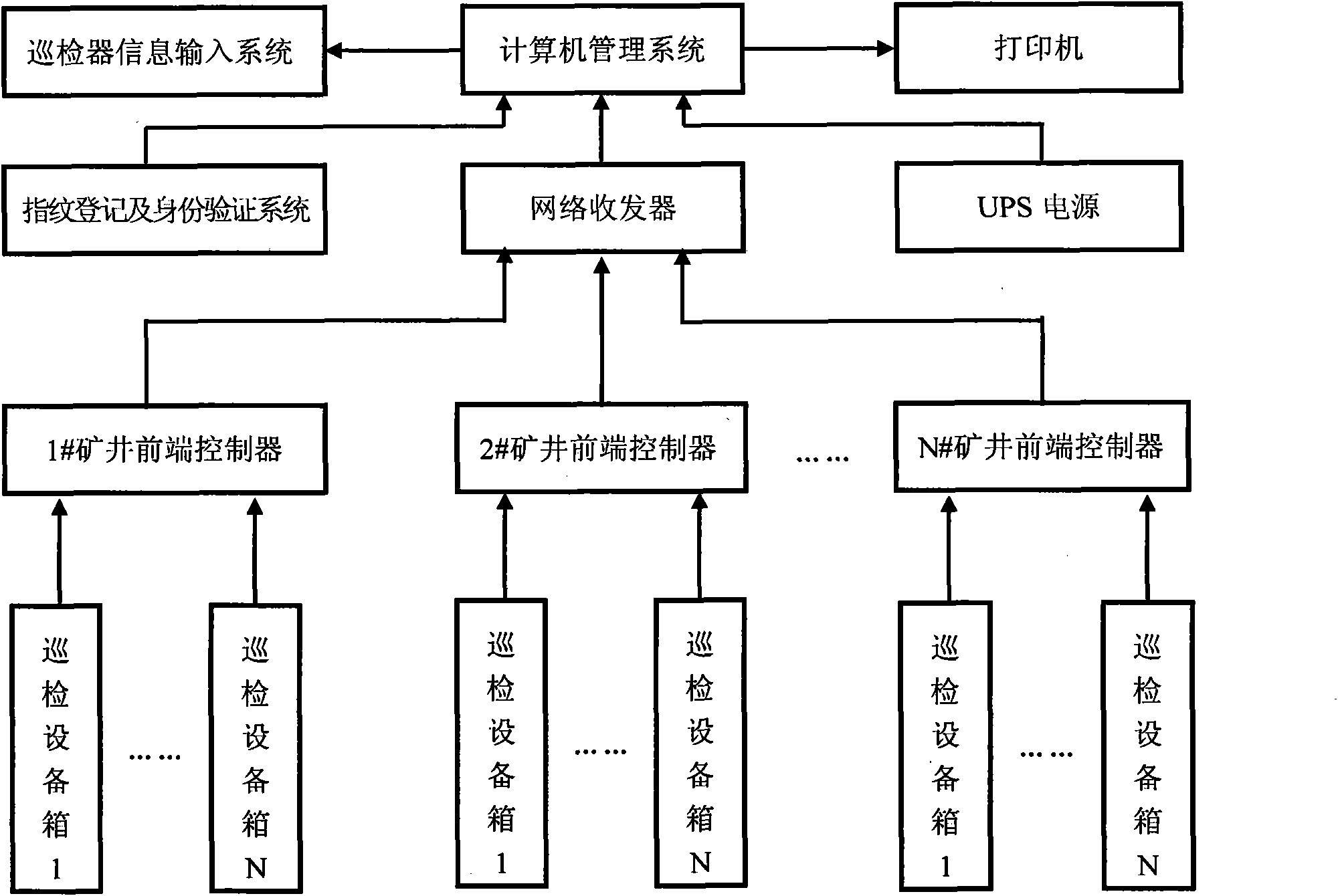

[0035] like Figure 1 As shown, the technical scheme and working process of the wired networking working mode of the present invention are as follows:

[0036] (1) Confirm the identity of the inspectors Before the inspection begins, the system first registers the fingerprint information of all inspectors. Generally, each inspector registers more than two fingerprints, one for each of the left and right hands. The fingerprint information is used to identify the inspectors true identity.

[0037] (2) The computer system inputs the personal information and inspection route of the inspector into the inspector to prove that the inspector is carried by the inspector, which is convenient for the management system to identify the inspector. At the same time, the system will set the inspection The route, time, and times are input to the inspection device, which records the identity, code and effective read and write permissions of the inspection personnel in the inspection activities; ...

Embodiment 2

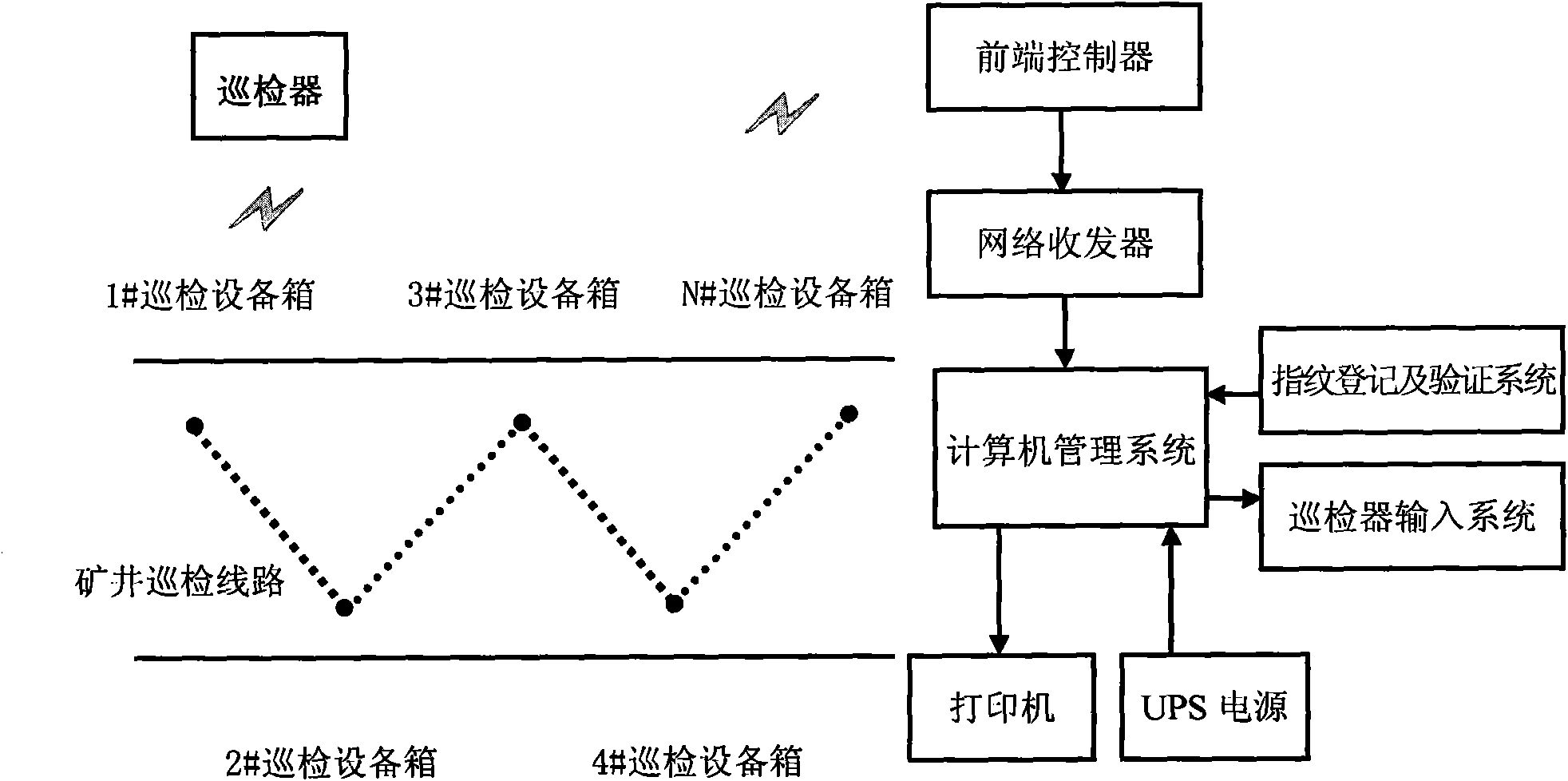

[0042] like Figure II Shown, the technical scheme and working process of the wireless networking working mode of the present invention (except having the whole working process of the wired networking working mode) are as follows:

[0043] (1) When the inspection personnel carry the inspection device and arrive at the equipment box of the 1# inspection point on the specified route, the equipment box of the inspection point will send it to the next inspection after receiving the identification code sent by the inspection device The check point equipment box performs relay transmission, and at the same time sends a signal to the patrol device, so that the sending circuit of the patrol device is in a dormant state to save power.

[0044] (2) When the inspector leaves the equipment box of the 1# inspection point with the inspector, the sending circuit of the inspector returns to the working state.

[0045] (3) When the inspection personnel carry the inspection device to the equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com