Linear transmission reciprocating-type internal combustion engine

A linear transmission, reciprocating technology, applied in the direction of machines/engines, mechanical equipment, etc., can solve problems such as low transmission efficiency, power damage, cylinder wear, etc., to achieve the effect of reducing power loss, prolonging service life, and ensuring reciprocating motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

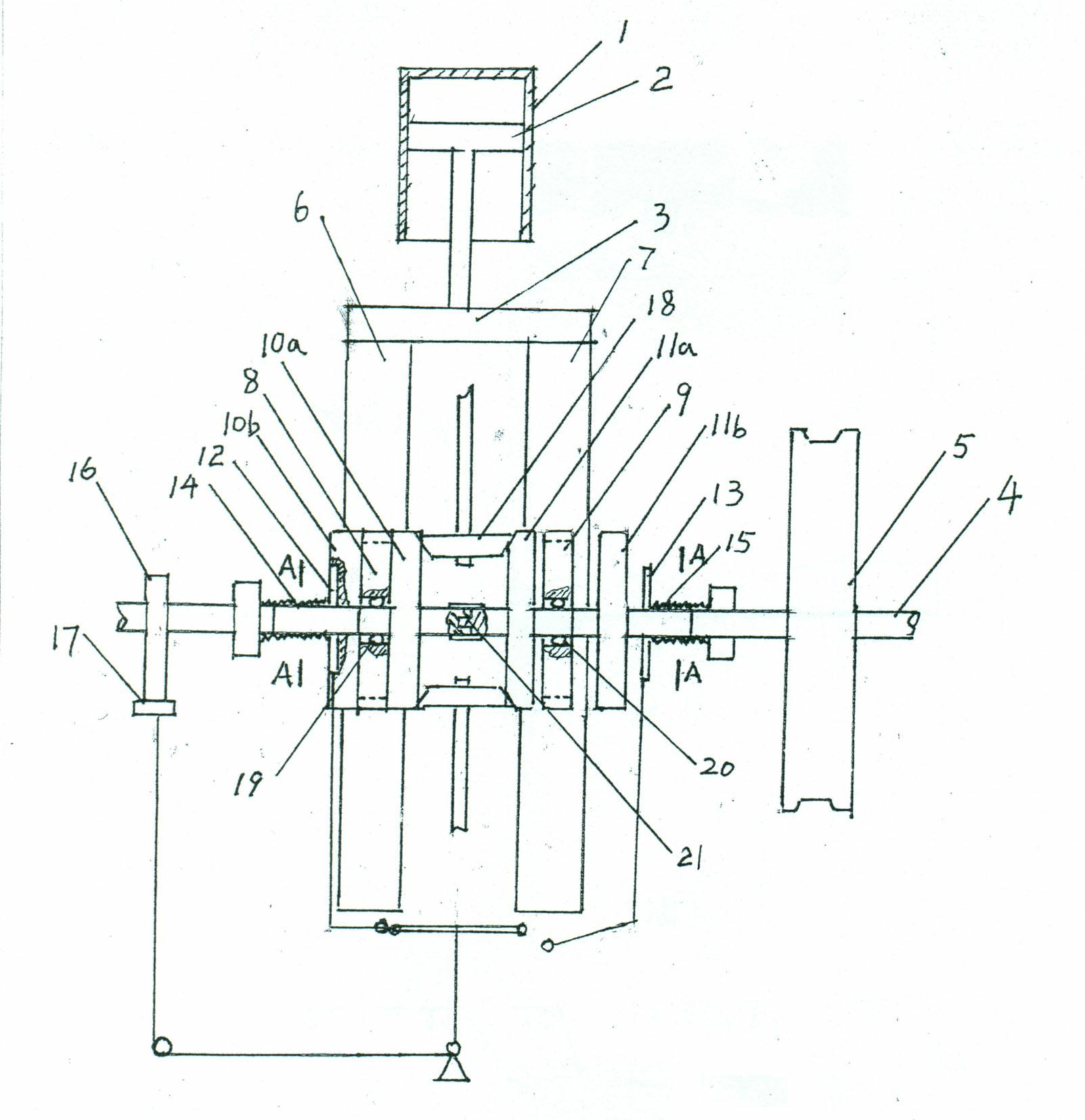

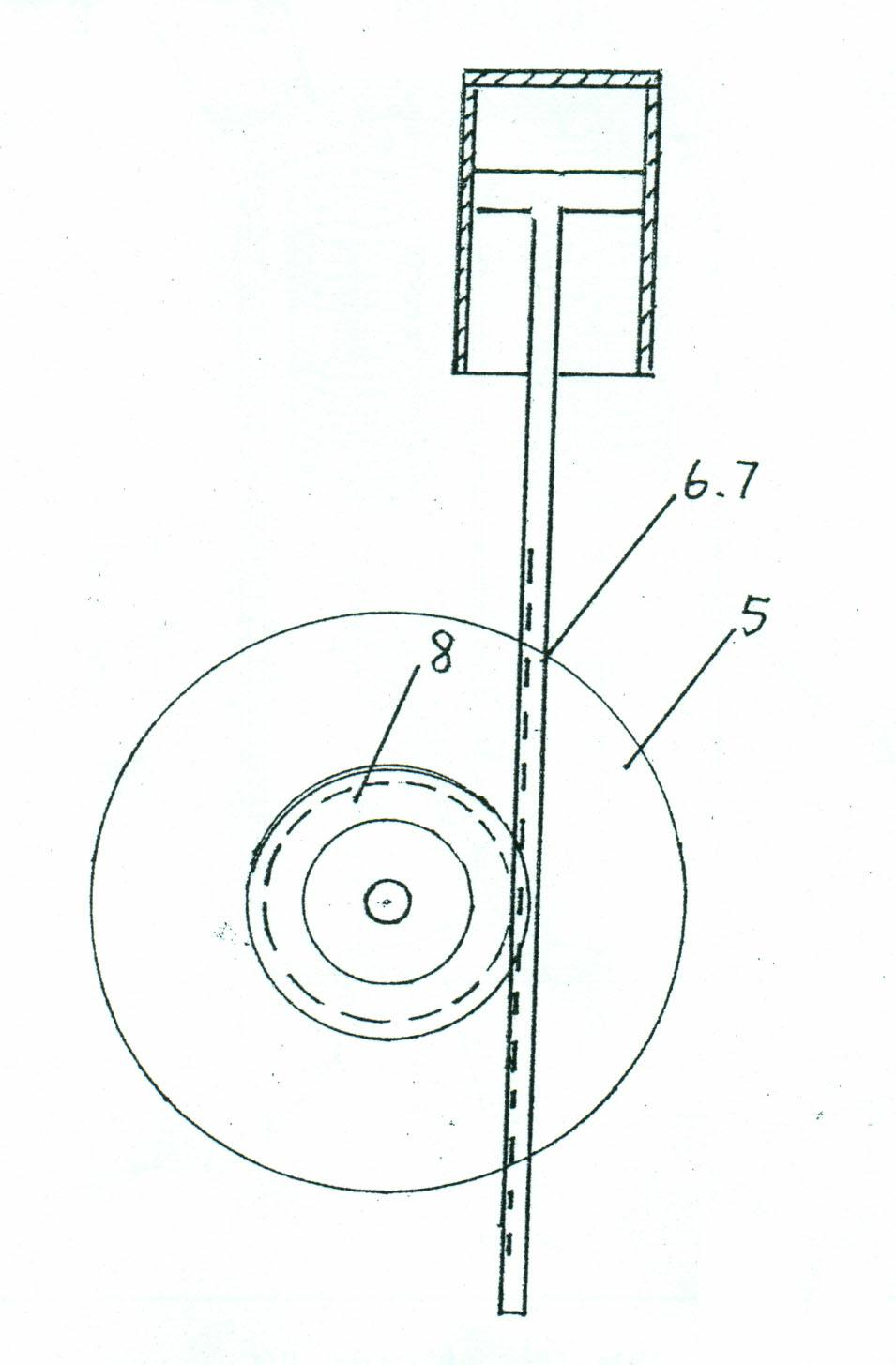

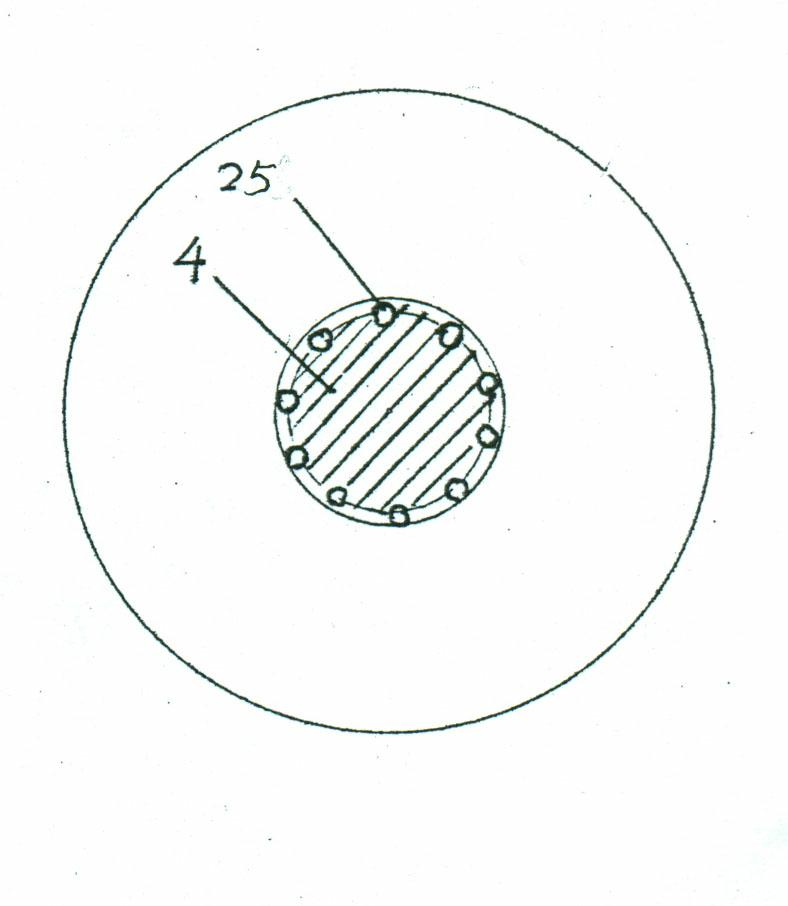

[0017] Example 1 see figure 1 , figure 2 , image 3 , Figure 5 , a reciprocating internal combustion engine, including a cylinder 1, a piston 2, a piston connecting rod 3, a transmission shaft 4, and a flywheel 5. The technical feature of this embodiment is that the piston connecting rod 3 connected to the piston 2 is set as two The structure of the transmission rack 6 and the reset rack 7 of the rack section, the rack section 6 meshes with the transmission gear 8 arranged on the transmission shaft 4; and a reset gear 9 is provided to mesh with the rack section 7; the transmission gear 8 and The reset gears 9 are floatingly connected to the transmission shaft 4, and the transmission shaft 4 is two coaxial sections, which are connected by a shaft connector 21; a pair of transmission flywheels 10a, 10a, 10b and a pair of reset pressure flywheels 11a, 11b, the transmission pressure flywheels 10a, 10b and reset pressure flywheels 11a, 11b can slide axially on a chute segment ...

Embodiment 2

[0019] Example two see Figure 4 , the present invention sets the rack section on the piston connecting rod 3 so that two adjacent vertical surfaces all have rack sections, and sets the cylinders 1 side by side as four cylinders A, B, C, and D, and the piston connecting rod 3 is 3a, 3b, 3c, 3d four; transmission gear 8 is respectively set to 8a, 8b, 8c, 8d four, and one side rack section of piston connecting rod 3a, 3b, 3c, 3d is respectively connected with the corresponding transmission The gears 8a, 8b, 8c, 8d are meshed, and the other rack segment is meshed with three cylinder linkage gears 22, 23, 24 meshed in series.

[0020] The working principle of this embodiment is that when the piston connecting rod 3a goes down, the exhaust port of cylinder A is closed, the air inlet is opened, and cylinder A starts to intake air; the intake and exhaust ports of cylinder B are closed, piston B starts to move upward, and the compression stroke begins ; while the C cylinder is in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com