Multi-stage backward gear speed changer with slide shaft roller keylock

A technology for reverse gears and sliding shafts, applied in gear transmissions, belts/chains/gears, instruments, etc., can solve problems such as large friction, and achieve the effects of small friction, light weight, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

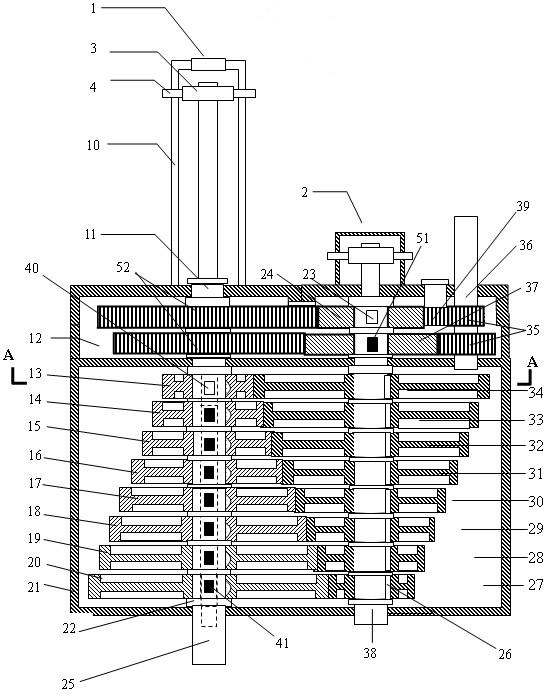

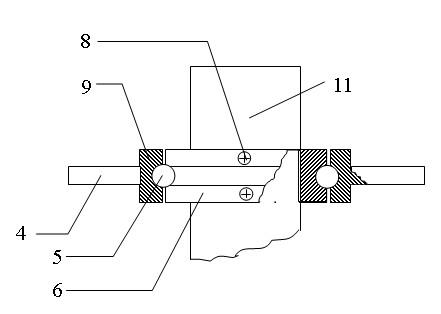

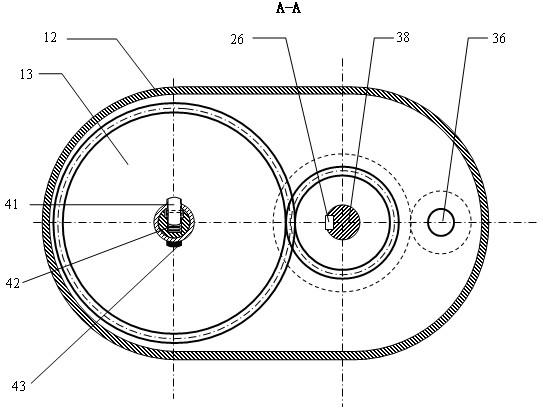

[0024] Attached below figure 1 , 2 , 3, 4, 5, 6, 7, 8 and Examples further illustrate the present invention.

[0025] The technical problem to be solved by the present invention is to provide a sliding shaft roller key lock multi-stage reverse gear transmission, which can replace the existing stepped transmission. It has the advantages of simple structure, low cost and reliable use; less gear components, light weight and small volume; multi-stage reverse gear speed regulation, etc.

[0026] Adopt the embodiment of the present invention to be: speed changer is made of final reduction mechanism, transmission gear, power take-off shaft, speed change gear, speed control ring, gear position speed control device, gear position state determining device, speed changer casing etc.

[0027] Basic structure: the engine inputs power to the power input shaft 36 through the clutch, and the two main transmission gears 35 mesh with the main reduction gear 37 and the reverse gear 24 respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com