Forward and reverse full-overrun gear shifting mechanism

A forward and reverse, second-gear technology, applied in mechanical equipment, gear transmission, belt/chain/gear, etc., can solve problems such as off-gear, flameout, engine lost rotation, slow response to speed changes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

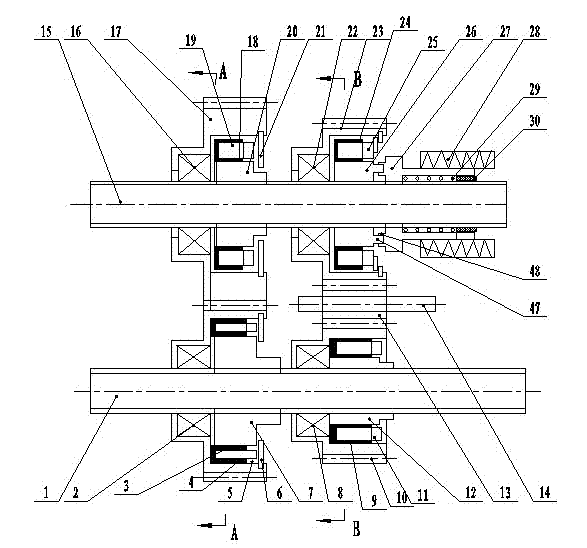

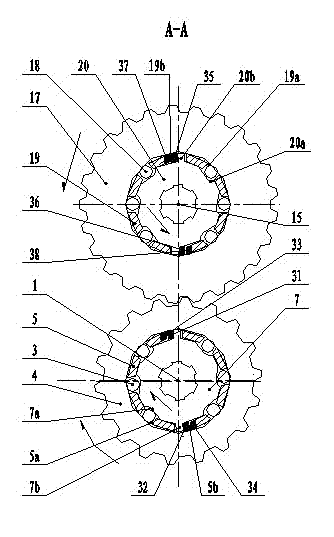

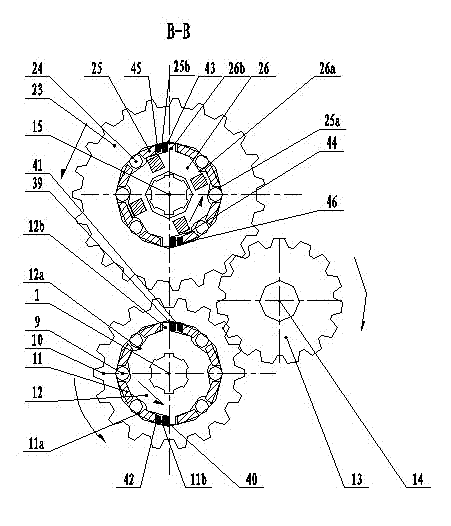

[0044] please join Figure 7 , Figure 8 , Figure 9 , Figure 16 and Figure 17 : the second gear driven unidirectional device includes a second gear driven wheel 23, the left part of the second gear driven wheel 23 is installed on the driven shaft 15 through the second gear driven bearing 22, and the second gear driven wheel 23 right The second gear driven cam 26 is installed in the center of the part, and the second gear driven cam 26 is looped on the driven shaft 15. Between the second gear driven cam 26 and the inner wall of the second gear driven wheel 23, a The second gear driven floating sleeve 25 is provided with a group of second gear driven cam curved surfaces 26a and two second gear driven convex posts 26b on the outer circumference of the second gear driven cam 26. The curved surface 26a and the two second gear driven cams 26b are evenly distributed on the outer circumference of the second gear driven cam 26, and the two second gear driven cams 26b are arrange...

Embodiment 2

[0046] please join Figure 10 , Figure 11 , Figure 12 , Figure 16 and Figure 17: the second gear driven unidirectional device includes a second gear driven wheel 23, the left part of the second gear driven wheel 23 is installed on the driven shaft 15 through the second gear driven bearing 22, and the second gear driven wheel 23 right The second gear driven cam 26 is installed in the center of the part, and the second gear driven cam 26 is looped on the driven shaft 15. Between the second gear driven cam 26 and the inner wall of the second gear driven wheel 23, a The second gear driven floating sleeve 25 is provided with a group of second gear driven cam curved surfaces 26a and two second gear driven convex posts 26b on the outer circumference of the second gear driven cam 26. The curved surface 26a and the two second gear driven cams 26b are evenly distributed on the outer circumference of the second gear driven cam 26, and the two second gear driven cams 26b are arran...

Embodiment 3

[0048] please join Figure 13 , Figure 14 , Figure 15 , Figure 16 and Figure 17 : the second gear driven unidirectional device includes a second gear driven wheel 23, the left part of the second gear driven wheel 23 is installed on the driven shaft 15 through the second gear driven bearing 22, and the second gear driven wheel 23 right The second gear driven cam 26 is installed in the center of the part, and the second gear driven cam 26 is looped on the driven shaft 15. Between the second gear driven cam 26 and the inner wall of the second gear driven wheel 23, a The second gear driven floating sleeve 25 is provided with a group of second gear driven cam curved surfaces 26a and two second gear driven convex posts 26b on the outer circumference of the second gear driven cam 26. The curved surface 26a and the two second gear driven cams 26b are evenly distributed on the outer circumference of the second gear driven cam 26, and the two second gear driven cams 26b are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com