Light source device and backlight module with same

A technology of a light source device and a backlight module, which is applied to parts, light sources, electric light sources, etc. The effect of reducing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

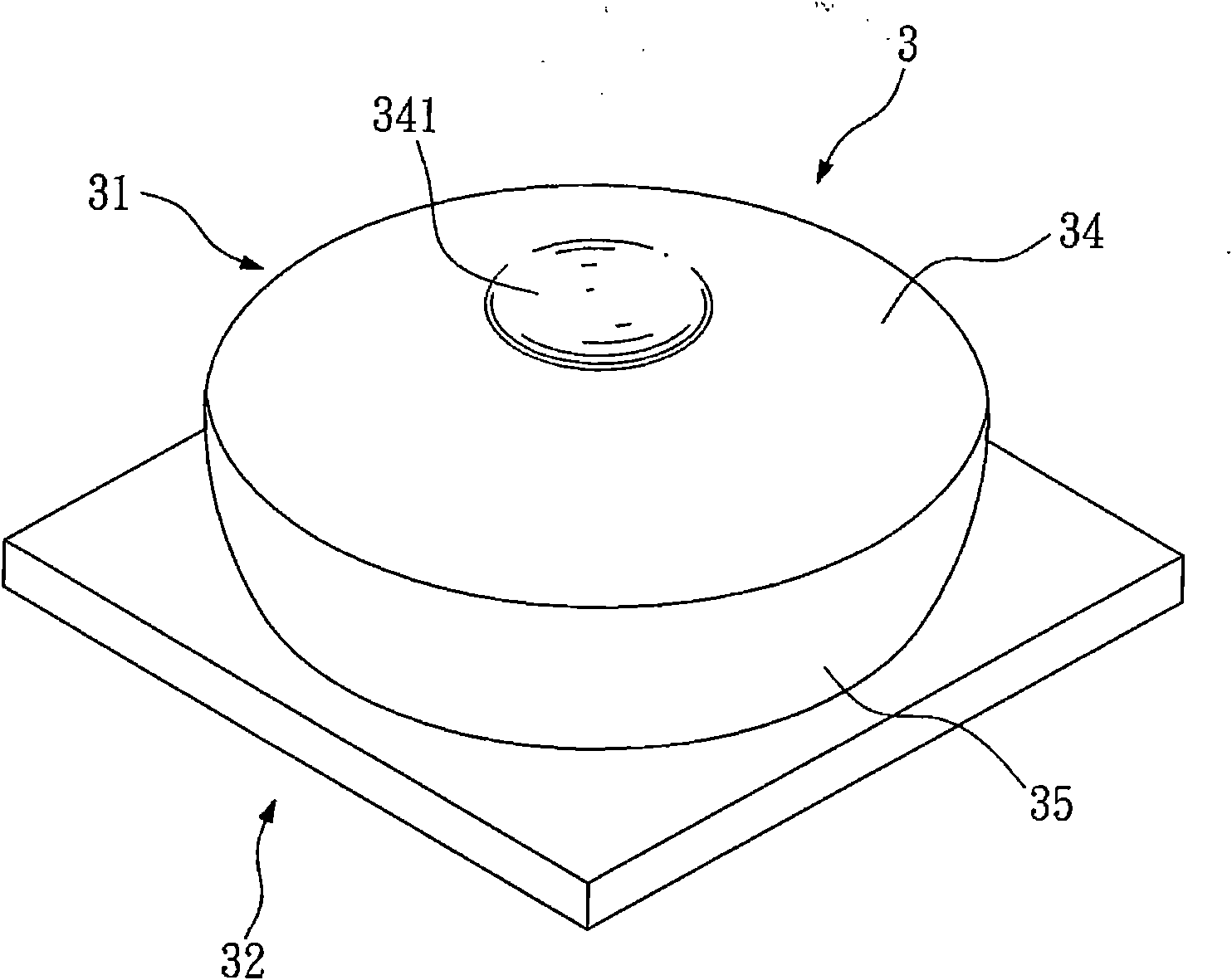

[0047] image 3 A perspective view showing the light source device of the present invention; Figure 4 A cross-sectional view of the light source device of the present invention is shown. with reference image 3 and Figure 4 , the light source device 3 includes a lens 31 and a light emitting diode 32 . Preferably, the material of the lens 31 can be polymethylmethacrylate (Polymethylmethacrylate, PMMA), but not limited thereto, any light-transmitting or light-guiding material can be applied to the material of the lens described in the present invention . The lens 31 has a bottom surface 33, an upper surface 34 and a side surface 35, the upper surface 34 is a diverging surface, the side surface 35 is a light-gathering surface, and the side surface 35 is adjacent to the bottom surface 33 and the upper surface 34, so as to In this embodiment, the side surface 35 is directly connected to the upper surface 33 . In addition, there may be a spacer surface (not shown) between th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elevation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com