Detection and transmission method and device of torque, load and rotational speed of screw pump pumping well

A technology for pumping wells and screw pumps, which is applied in the detection field of screw pump pumping wells, which can solve problems such as heavy workload, cumbersome detection process, and eccentric wear of rods and tubes, so as to achieve reasonable device structure, ensure accuracy, and ensure safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is further described below in conjunction with embodiment and accompanying drawing.

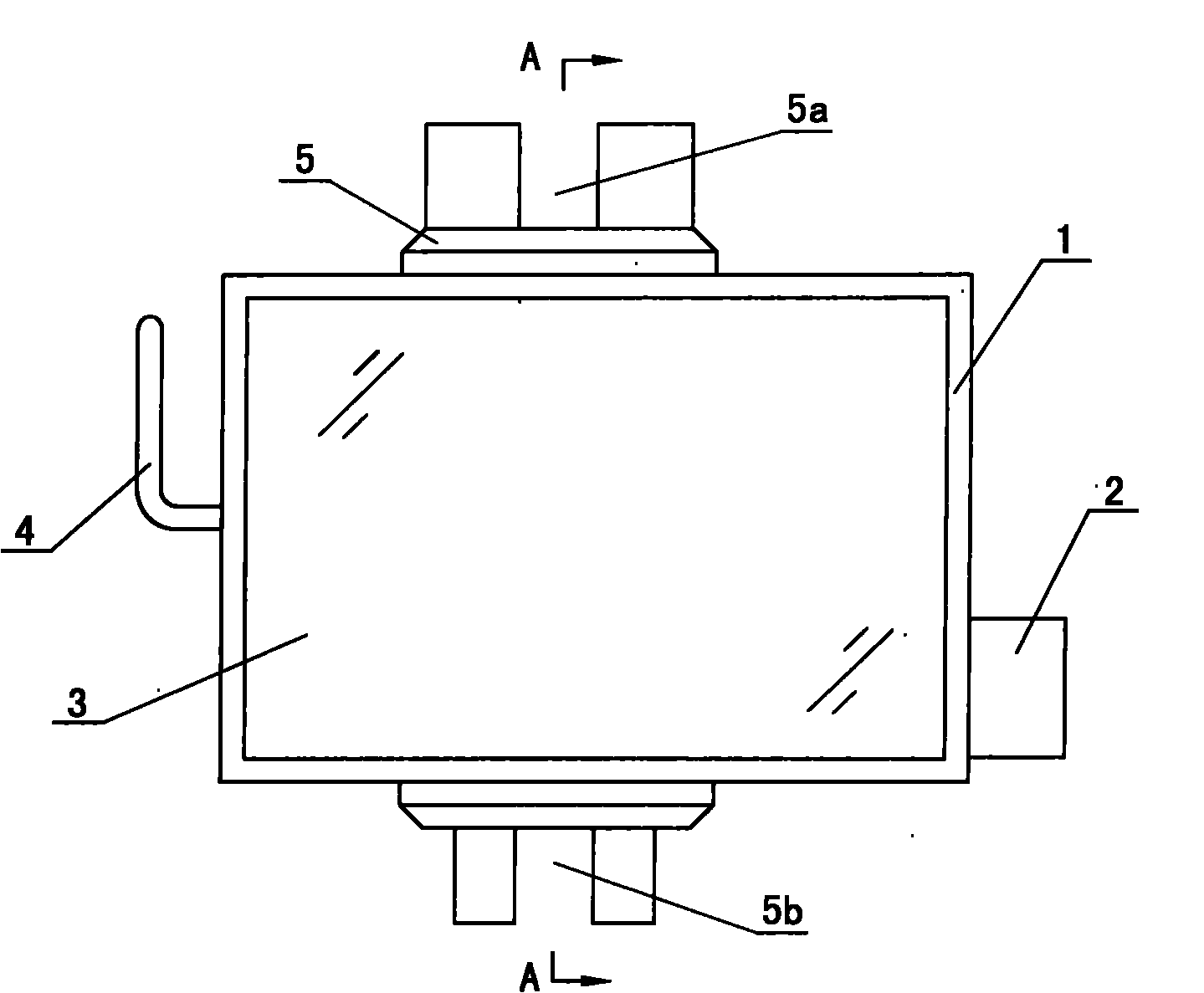

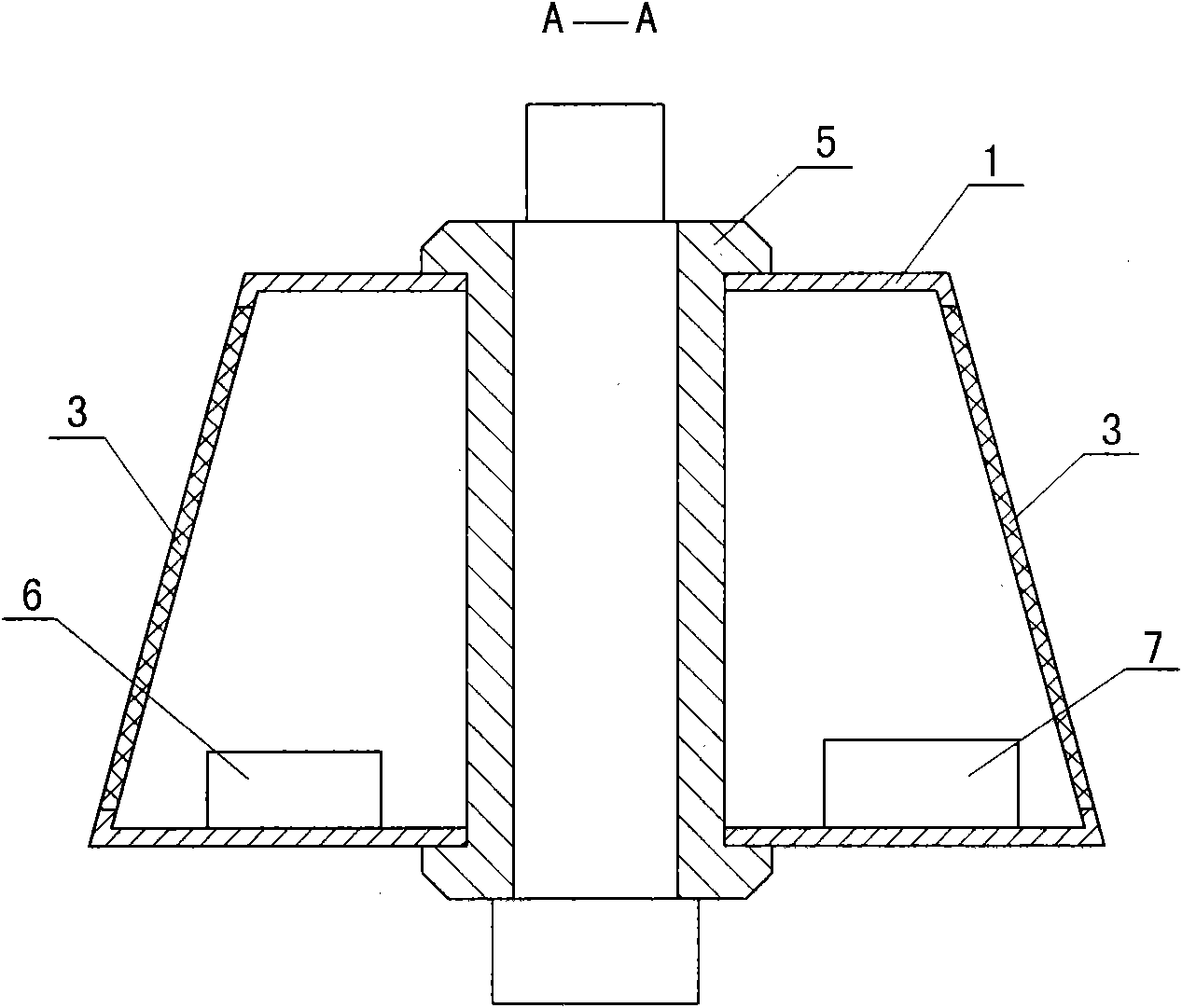

[0013] see figure 1 , figure 2

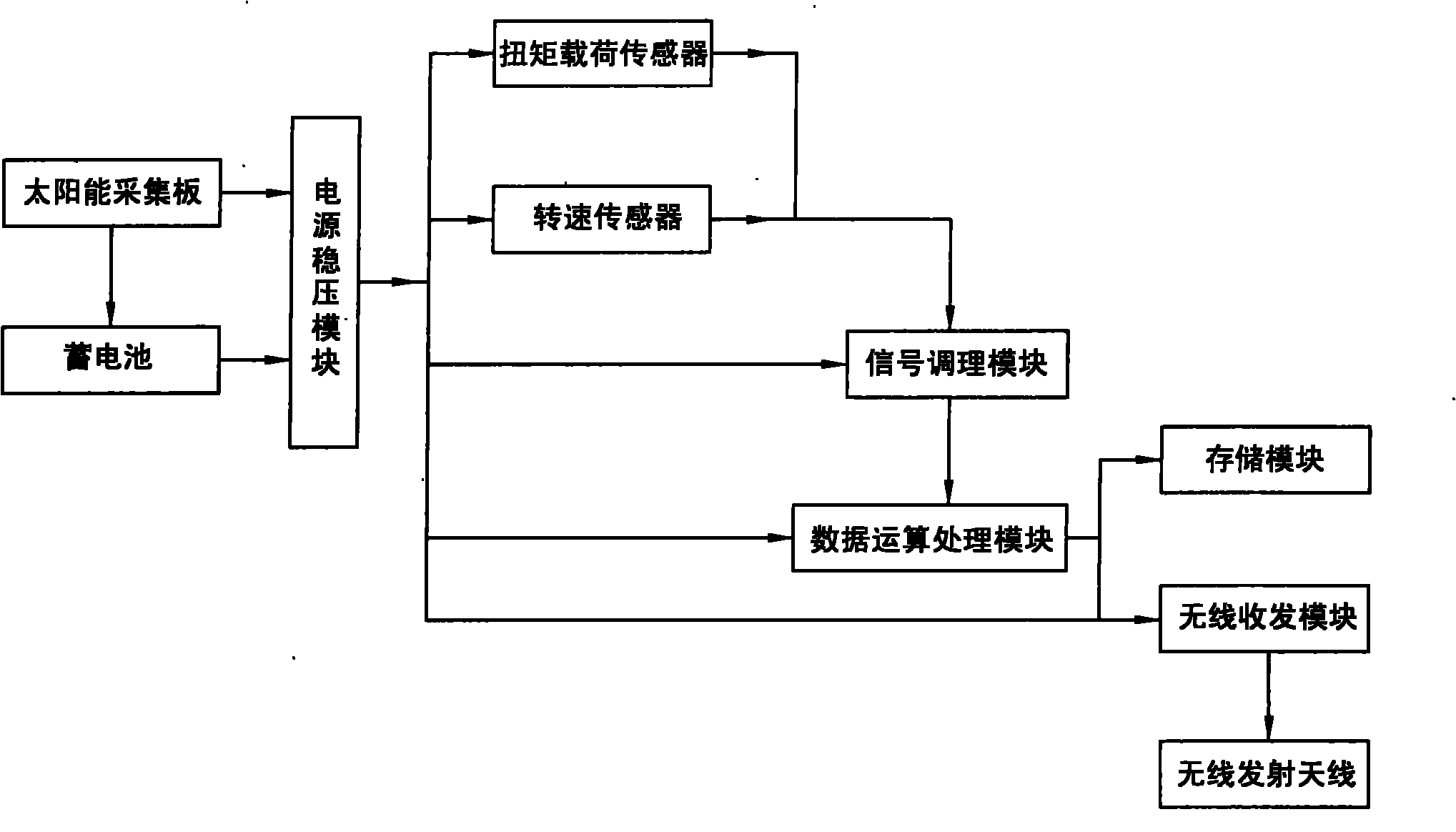

[0014] The screw pump pumping unit torque, load, rotational speed detection transmission device provided by the present invention has a shell 1, and the torque load sensor 5 is housed on the shell 1, and the two ends of the torque load sensor 5 extend from the upper and lower ends of the shell 1 respectively. The two ends of the torque load sensor 5 have "U"-shaped bayonet socket 5a and bayonet socket 5b respectively, the rotational speed sensor 2 is installed on one side of the casing 1, and the solar energy collecting board 3 and the wireless transmitting antenna are installed on the outside of the casing 1. 4. A storage battery 6 and a circuit board assembly module 7 are arranged inside the casing 1, and the circuit board assembly module 7 is composed of a power supply voltage stabilization module, a signal conditioning modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com