Reflective film laminate

一种反射膜、层叠体的技术,应用在反射器、涂层、分层产品等方向,能够解决反射膜透明化反射率下降等问题,达到抑制溶出和氧化、高反射率、维持反射率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

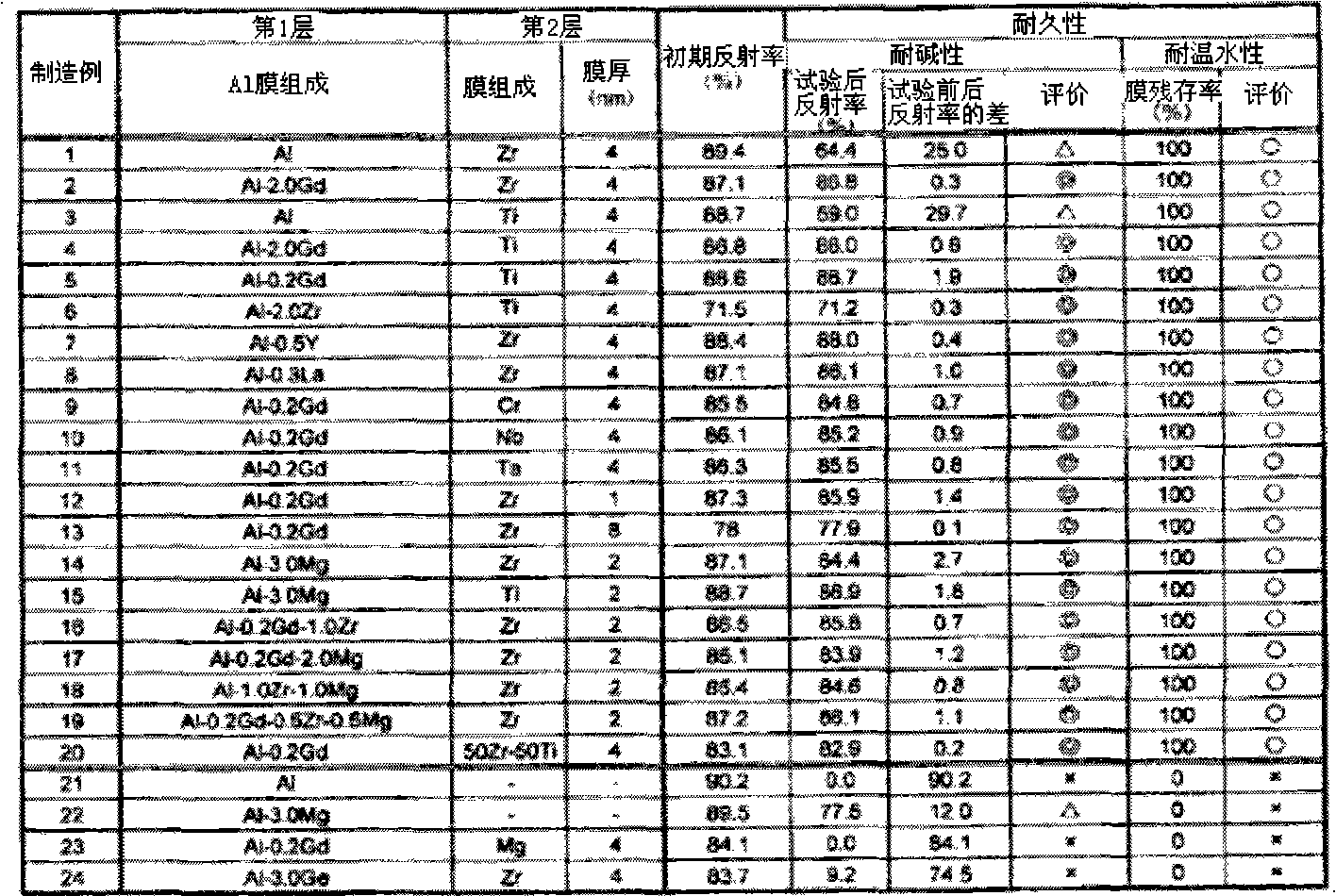

manufacture example 1~24

[0074] The substrate uses polycarbonate (PC) with a diameter of 50.8 mm×thickness 1 mm, and the sputtering target uses pure Al or an Al-based alloy sputtering target with a diameter of 101.6 mm×thickness 5 mm. First, evacuate to make the pressure in the sputtering chamber 1×10 -3 Below Pa. Next, Ar gas was introduced into the sputtering chamber, so that the pressure in the sputtering chamber was 2.6×10 -1 Pa, DC (direct current) power of 250 W was applied to the electrode to generate plasma, and the sputtering target was sputtered to form the first layer (Al film) on the PC substrate. The distance between the sputtering target and the PC substrate is 80mm, and the PC substrate is formed while revolving.

[0075] The formation of the second layer is that after the Al film of the first layer is formed, the sputtering chamber is not opened, and the Ar gas is introduced into the sputtering chamber so that the pressure in the sputtering chamber is 2.6×10 -1 Pa is performed by sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectivity | aaaaa | aaaaa |

| hygroscopic ratio | aaaaa | aaaaa |

| hygroscopic ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com