Light guide plate and light-emitting diode (LED) lamp containing same

A technology of LED lamps and light guide plates, applied in the directions of optics, light guides, light sources, etc., can solve the problems of difficult control of light uniformity, low light utilization rate, low light utilization rate, etc., and achieve the effect of reducing the glare phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiments of the present invention will be described below mainly in conjunction with the accompanying drawings.

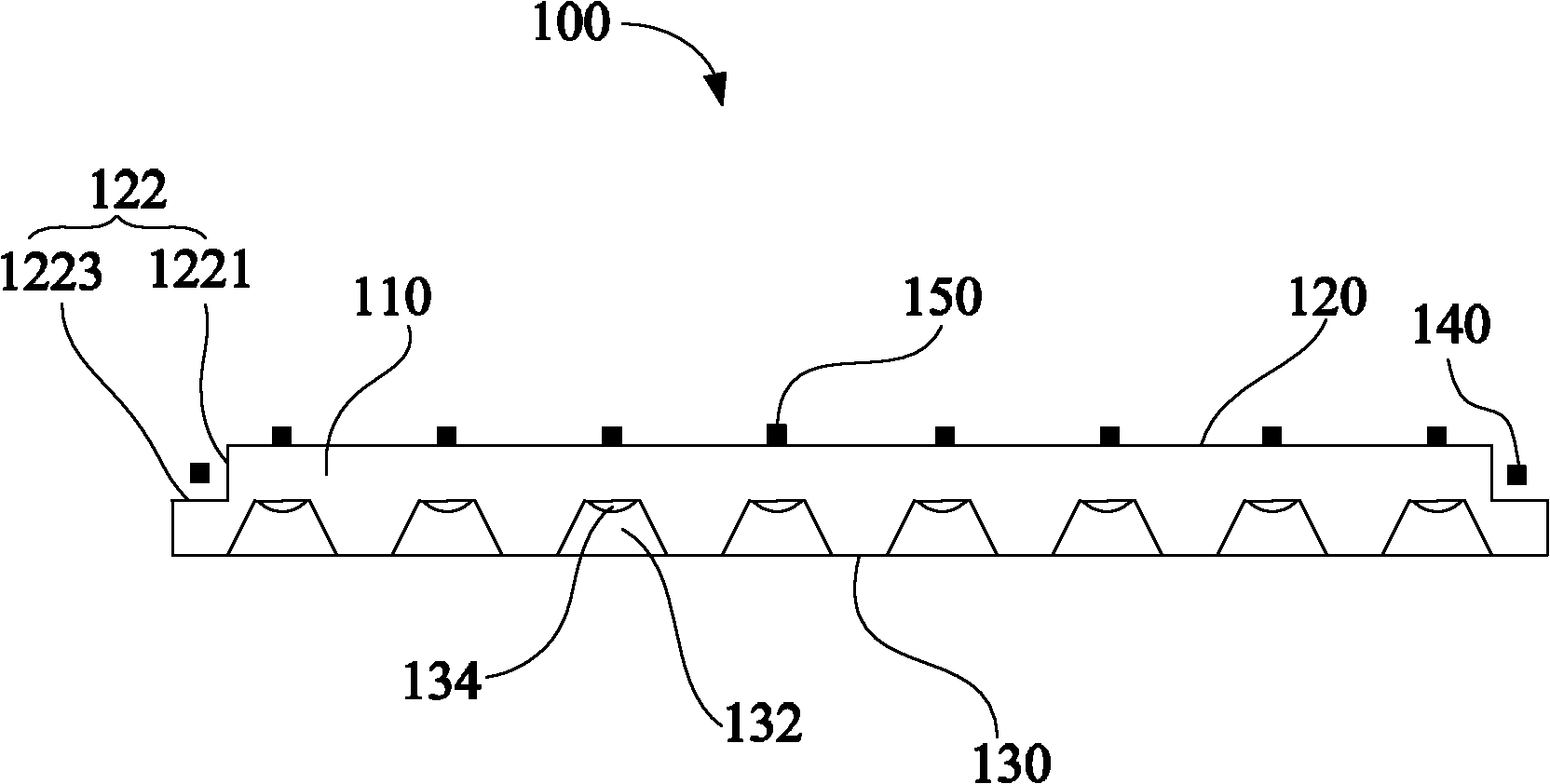

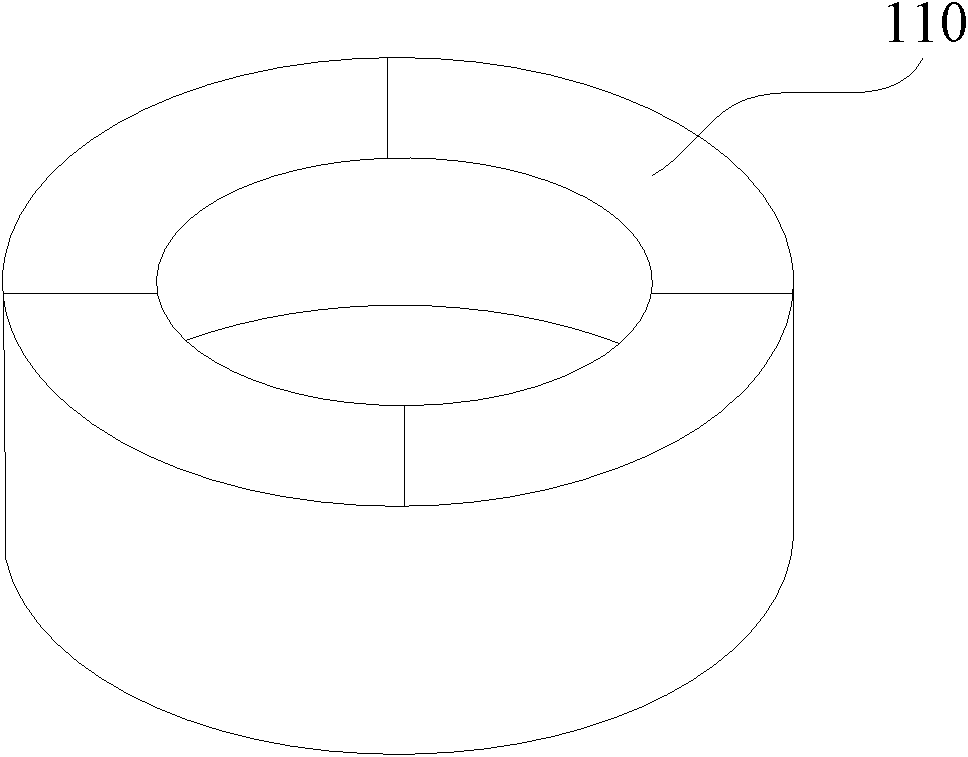

[0036] see figure 1 , the LED lamp 100 of Embodiment 1 includes a light guide plate 110 , a first LED light source 140 and a second LED light source 150 . The light guide plate 110 includes a transparent base (not shown), a light incident surface 120 and a light exit surface 130 .

[0037] In this embodiment, the transparent substrate is roughly rectangular, and it can be formed of a transparent resin material, for example, one or a combination of acrylic resin, polycarbonate resin, polystyrene resin and styrene-methyl methacrylate resin .

[0038] The light incident surface 120 is formed on the transparent base. The light incident surface 120 is substantially rectangular, and two sides thereof are formed with stepped portions 122 for accommodating the light source. The stepped portion 122 includes a first stepped surface 1221 and a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com