Focal plane assembly capable of realizing same viewing field splicing

A field of view splicing and focal plane technology, which is applied in the field of aerospace optical remote sensors, can solve the problems of difficulty in seamless splicing of the same field of view, inability to achieve seamless splicing, and reduced electrical performance, so as to improve the level of integration and functional density. , to avoid mutual interference, to expand the effect of the coverage width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

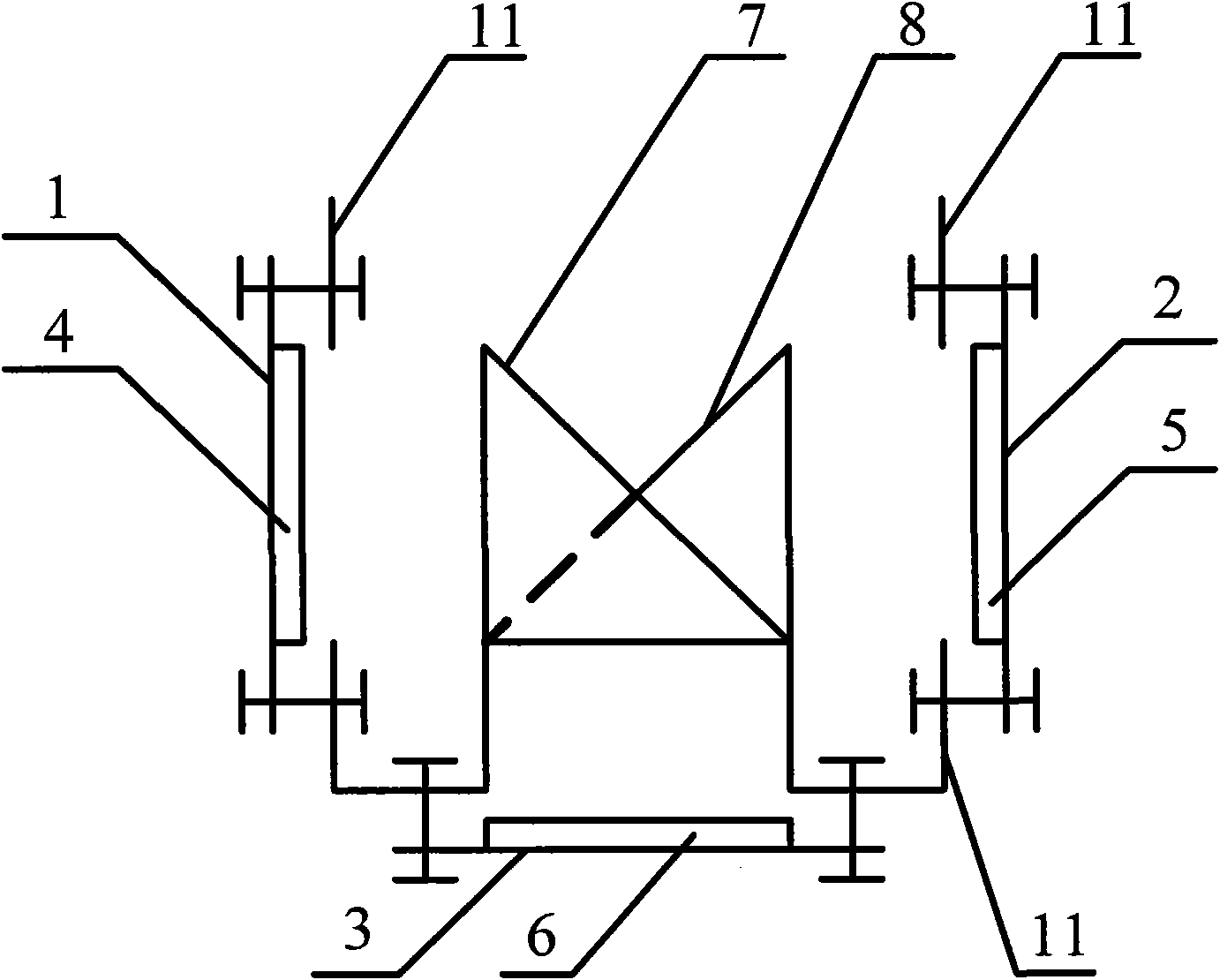

[0020] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

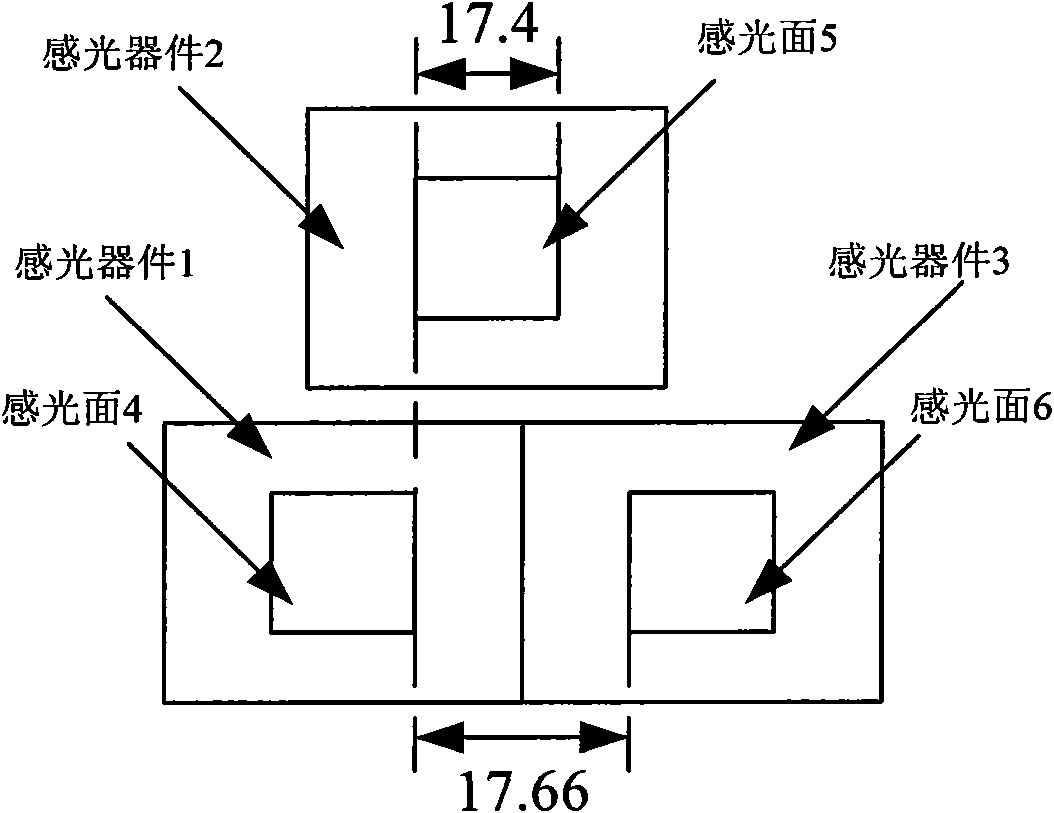

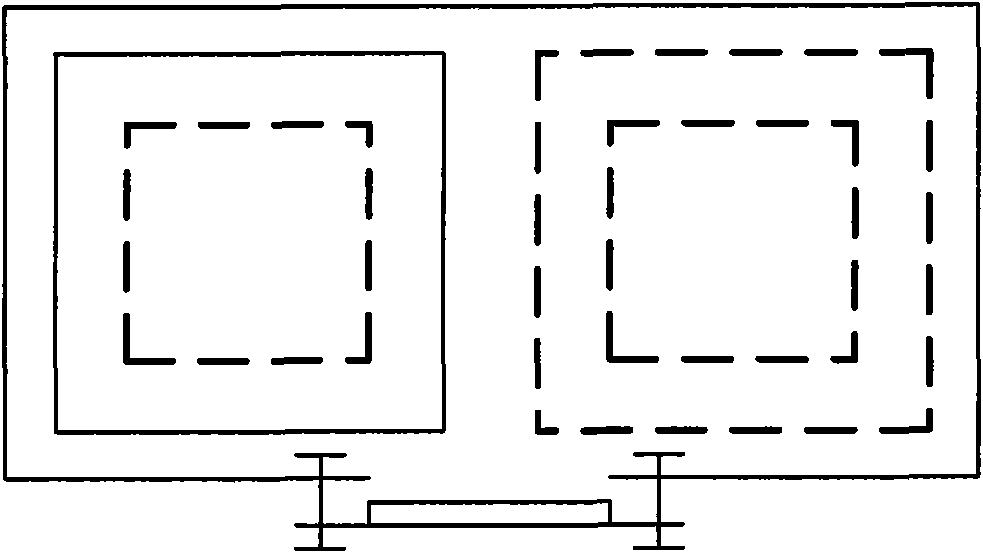

[0021] Such as figure 1 As shown, the present invention aims at the problem of missing pixels when the physical packaging size of the photosensitive device in the splicing direction is greater than twice the length of the photosensitive surface of the photosensitive device in the splicing direction. A photosensitive device refers to a photoelectric conversion device, which can be a linear array, an area array, etc., including a photosensitive surface and its peripheral packaging, such as a common CMOS photosensitive device or a CCD photosensitive device. The photosensitive surface of the photosensitive device is a square or rectangular photosensitive area composed of independent square or rectangular photosensitive pixels, and its center is generally located at the center of the photosensitive device. The length of the border between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com