Full automatic edible fungus bag loosening aerator

An edible fungus, fully automatic technology, applied in the fields of application, horticulture, botanical equipment and methods, etc., can solve the problems of low efficiency, inability to loosen materials, prick dozens of times or beat several times, etc., to achieve the effect of oxygenation Excellent, high perforation efficiency, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

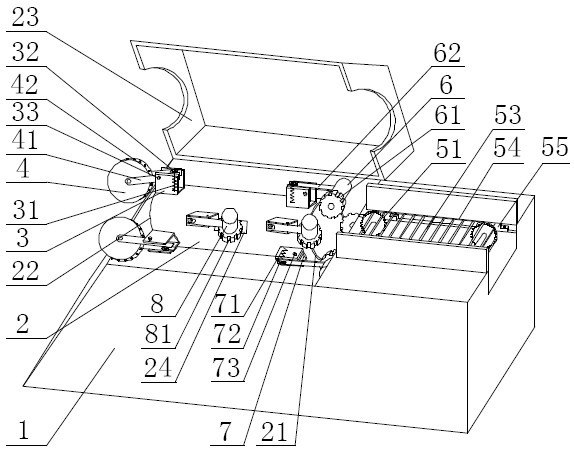

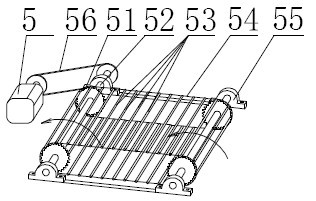

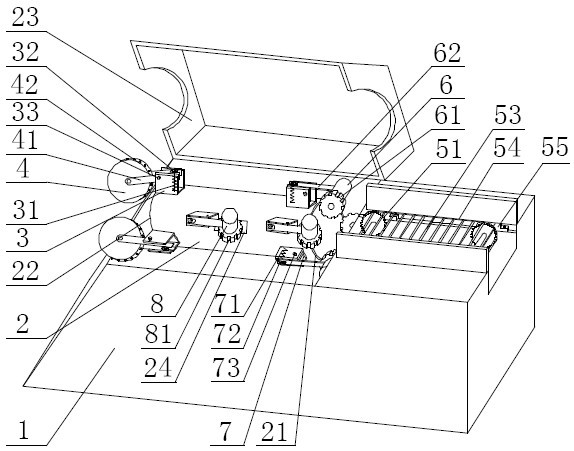

[0015] refer to figure 1 , figure 2 , the full-automatic edible fungus bag loose material aeration machine of the present invention comprises a base 1, a hollow cylinder 2 is fixed on the base 1, and the bag outlet 22 of the cylinder 2 is evenly distributed and useful Piercing wheel 4 for puncturing and increasing oxygen in the bacteria bag, several second spring seats 3 are fixed on the periphery of the bag outlet 22 of the cylinder 2, and the piercing wheel 4 connects with the movable handle 41 at the center The second spring 31 in the second spring seat 3 is connected, and the outer circumference of the puncture wheel 4 is provided with a plurality of puncture needles 42, and the cylinder 2 is provided with a fungus bag on the outside of its bag inlet 21 for conveying. mechanism, the bacteria bag is transferred from the conveying mechanism to the bacteria bag feeding mechanism in the cylinder 2;

[0016] Described conveying mechanism is the sprocket conveying mechanism d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com