Mine track laying method and rock tunnel cutting machine

A laying method and cutting machine technology, applied in the direction of track, movable track, laying track, etc., can solve problems affecting cutting accuracy, potential safety hazards, loose wood blocks, etc., and achieve the effect of simplifying cutting, improving efficiency, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

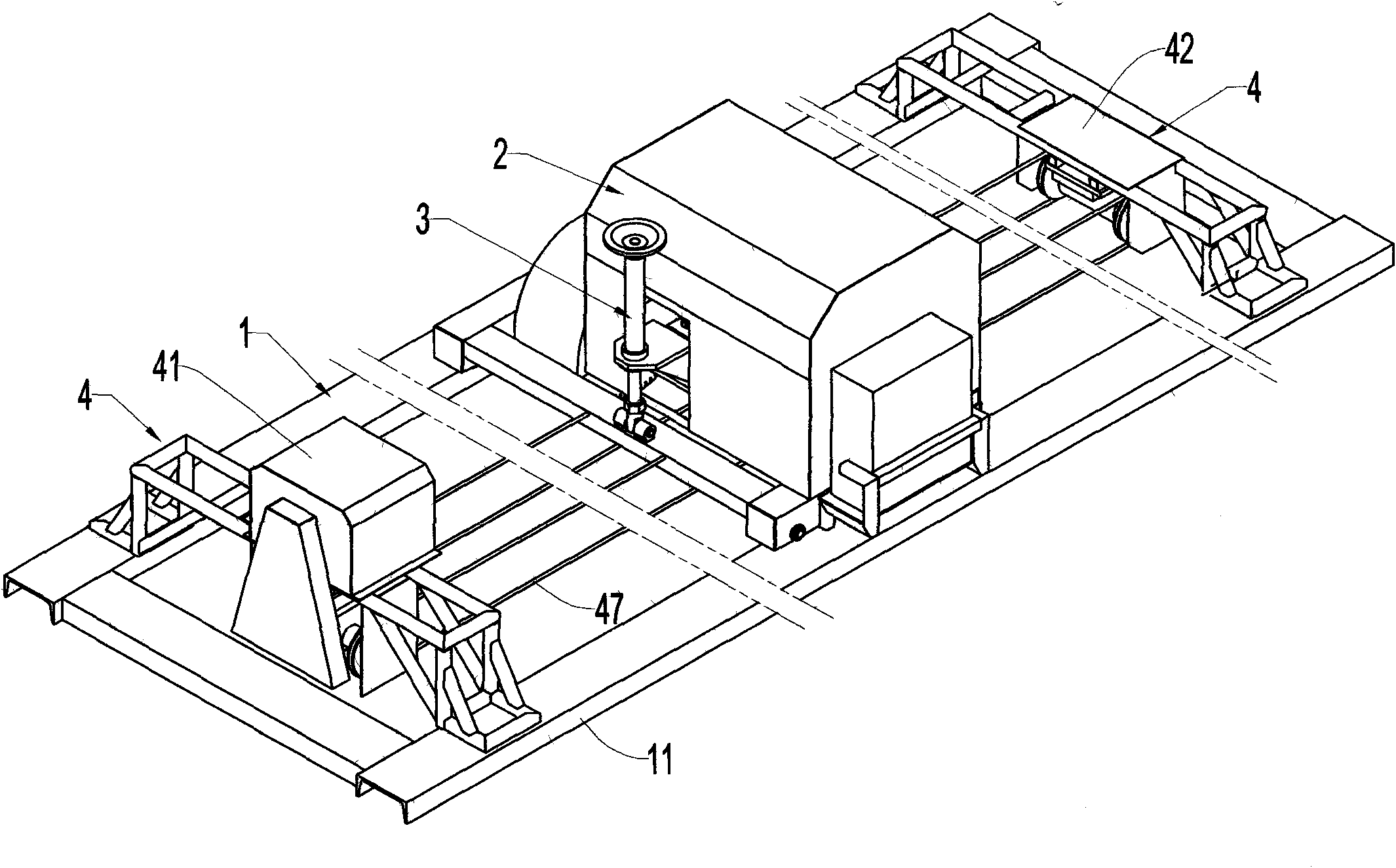

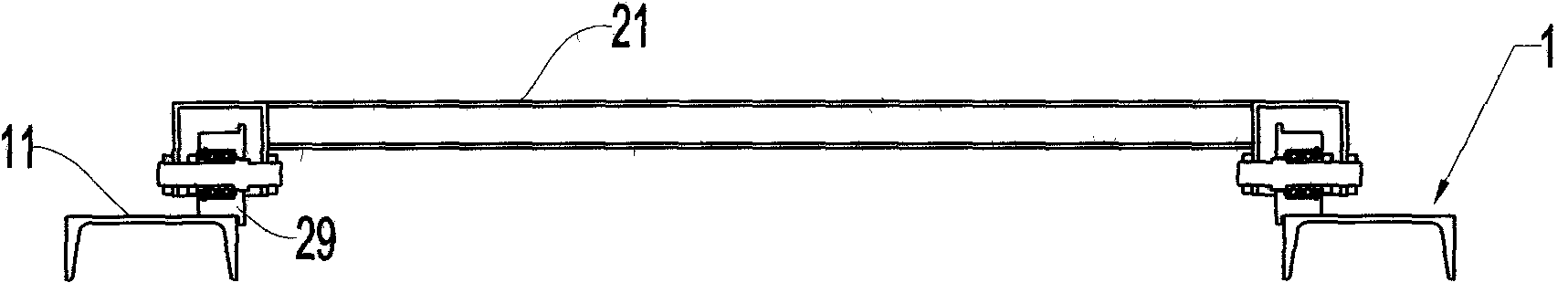

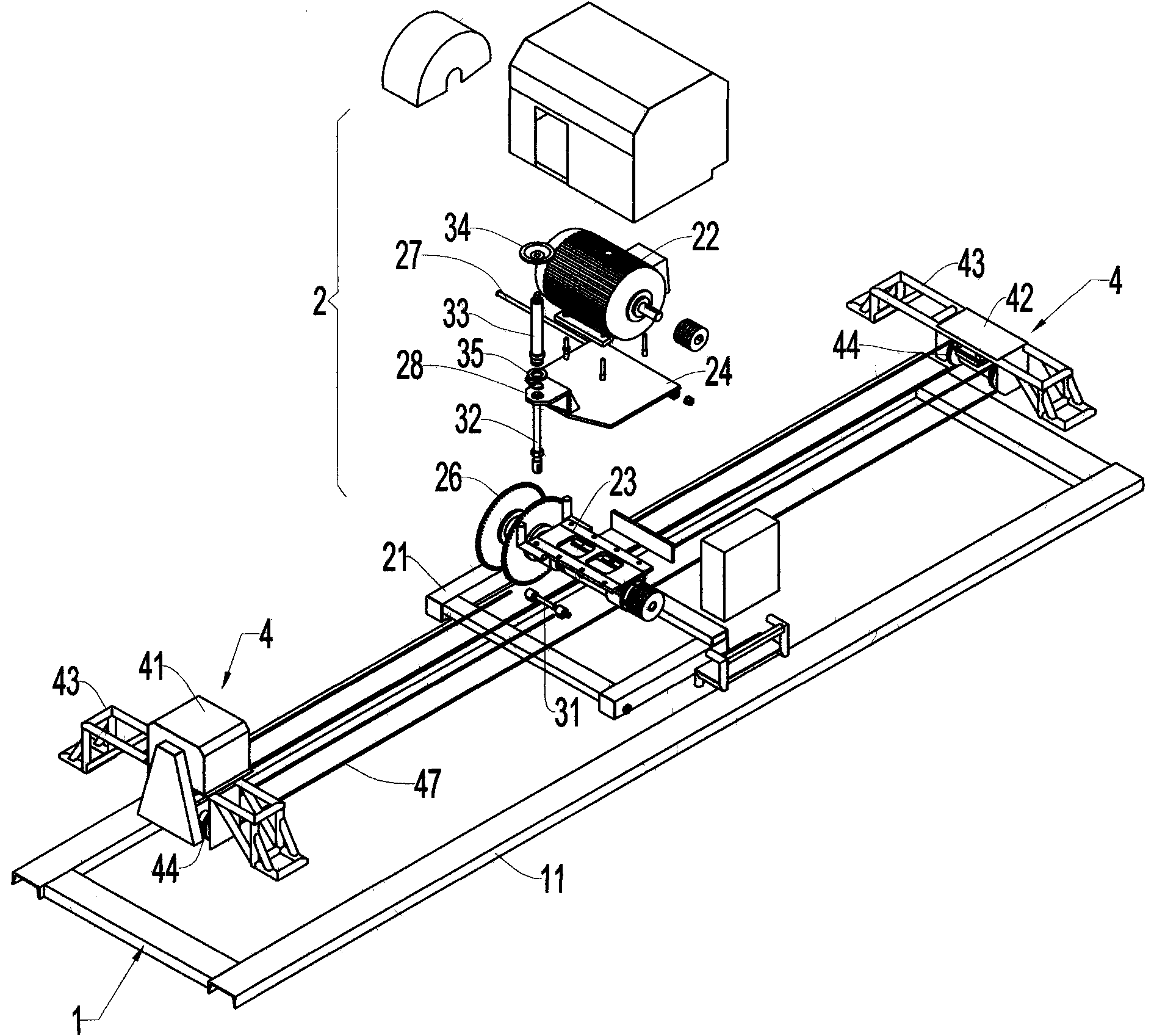

[0041] refer to Figure 1 to Figure 6 , the stone seam cutting machine used for mine track laying includes a walking frame 1 and a cutting machine 2, wherein two long sides 11 are used for the cutting machine 2 to walk; a traction mechanism 4 is provided between the two ends of the walking frame 1, and the two ends described here That is, the two short sides of the square structure.

[0042] Such as image 3 , Figure 4 and Figure 5 , cutting machine 2 comprises a base 21, the base plate 24 that is fixed with motor 22 and spindle box 23, and the saw blade 26 that is fixed on the output shaft 25; Base plate 24 upper surface is fixed with motor 22, and spindle box 23 is installed on the lower surface; One end of the output shaft 25 in the main shaft box 23 is driven by the motor shaft belt, and the other end of the output shaft 25 is fixed with two adjustable saw blades 26. The distance between the two saw blades 26 is determined according to the distance between the legs of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com