Insulation structure for cup rim column foundation

A technology of column foundation and cup mouth, which is applied in the field of new construction to solve the insulation of cup mouth column foundation, can solve problems such as narrow construction surface, failure to meet insulation requirements, geometric dimensions that are difficult to meet the needs of engineering construction, etc., to improve reliability The effect of sex and small error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

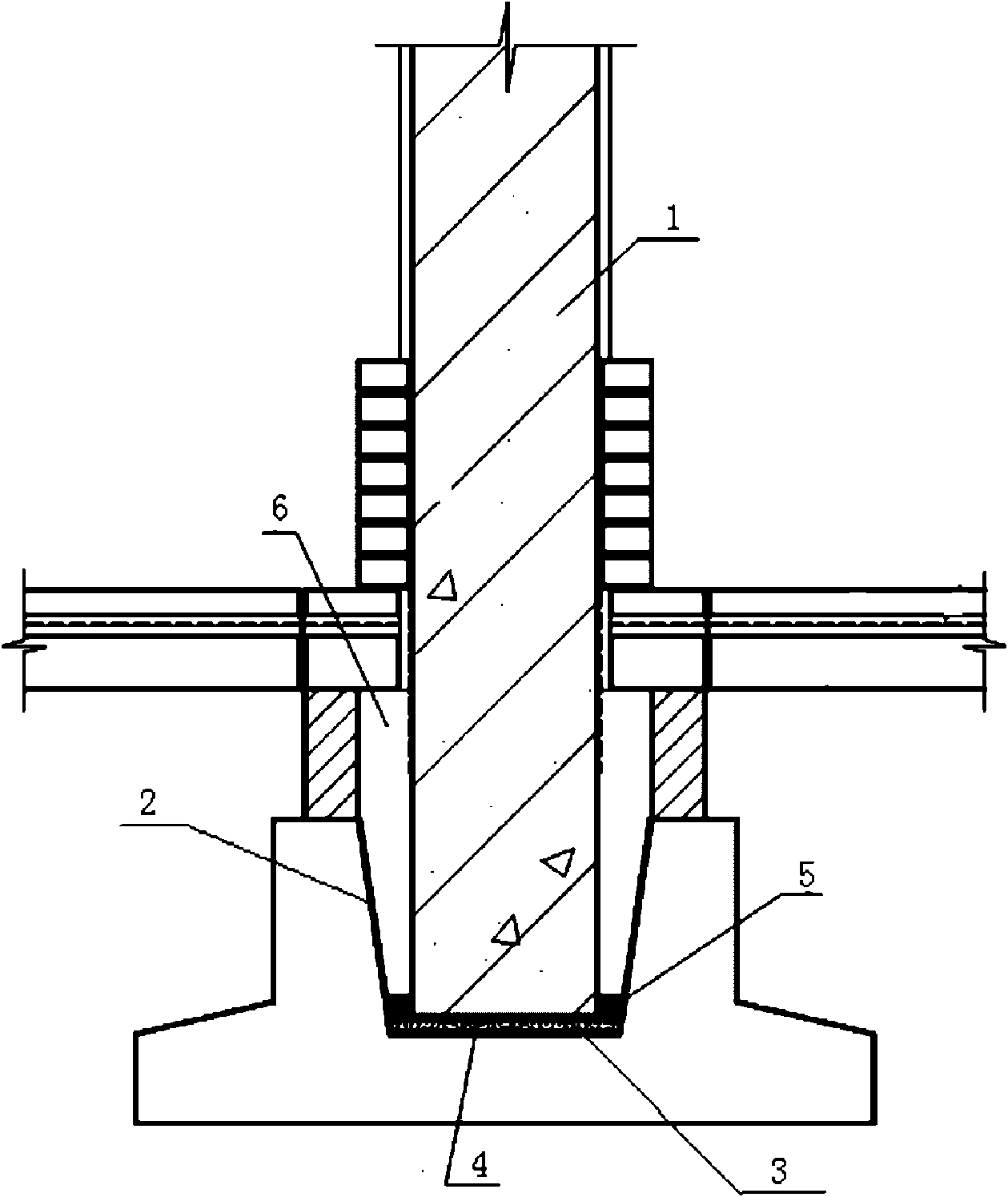

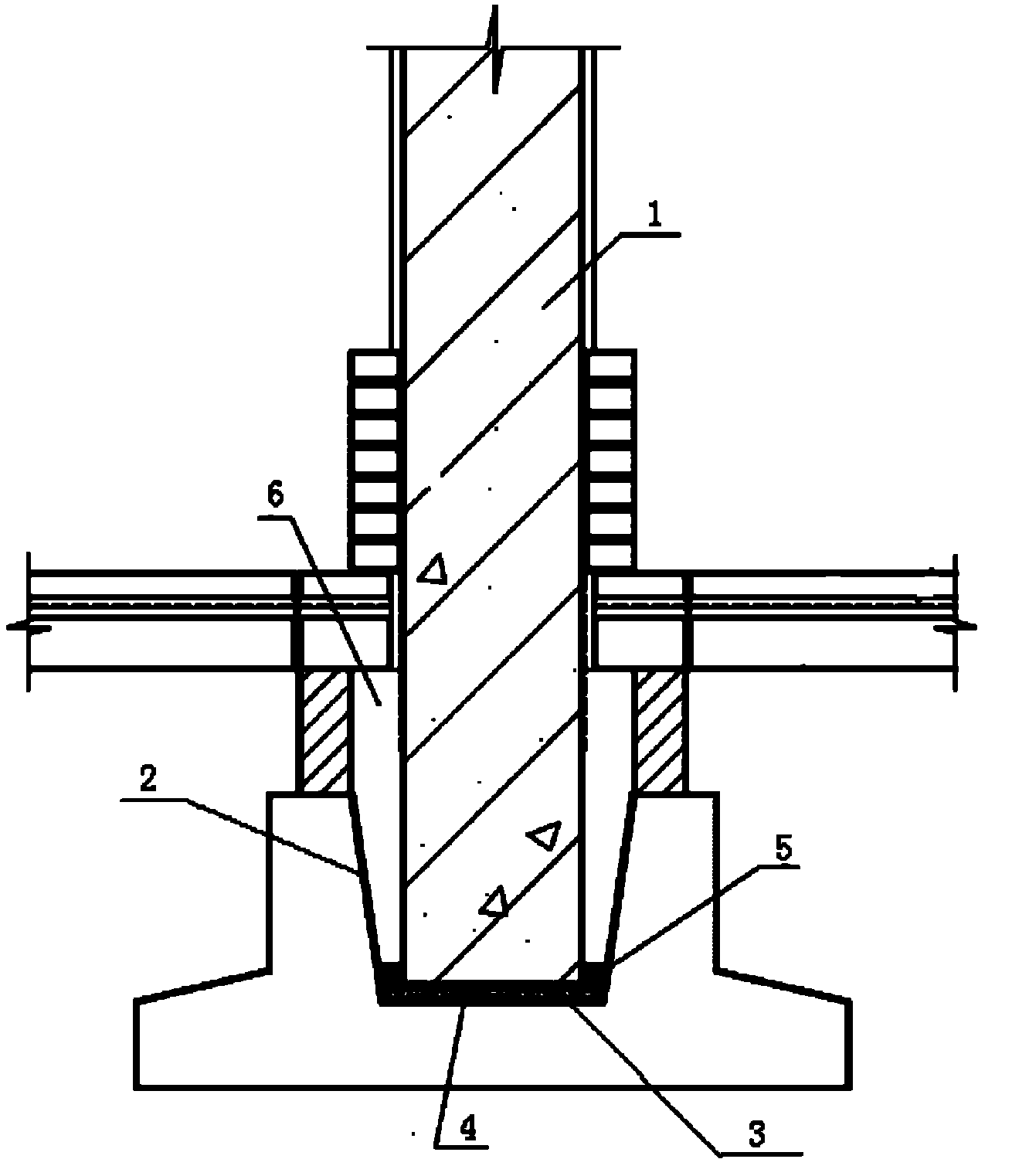

[0012] Example 1: The insulating structure of the base of the cup mouth column, such as figure 1 As shown, the stigma 1 is wrapped with three bottoms, one greasy and four cloths (using epoxy bisphenol resin glass fiber reinforced plastic), which is located in the mouth of the cup, with a height of 200mm from the floor. It is 5mm, the bottom of the cup mouth is epoxy mortar leveling layer 3, the thickness is 20mm, the upper layer of epoxy mortar leveling layer 3 is rubber layer 4, its thickness is 10mm, the rubber layer 4 is paved with epoxy bisphenol resin, and the column head 1 is connected to the rubber layer 4, the gap between the stigma 1 and the cup mouth is filled with pure polymer resin 5 at the bottom, the thickness is 50mm, the upper part is filled with polymer mortar 6, and the entire stigma is filled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com