Heat pipe and manufacturing method thereof

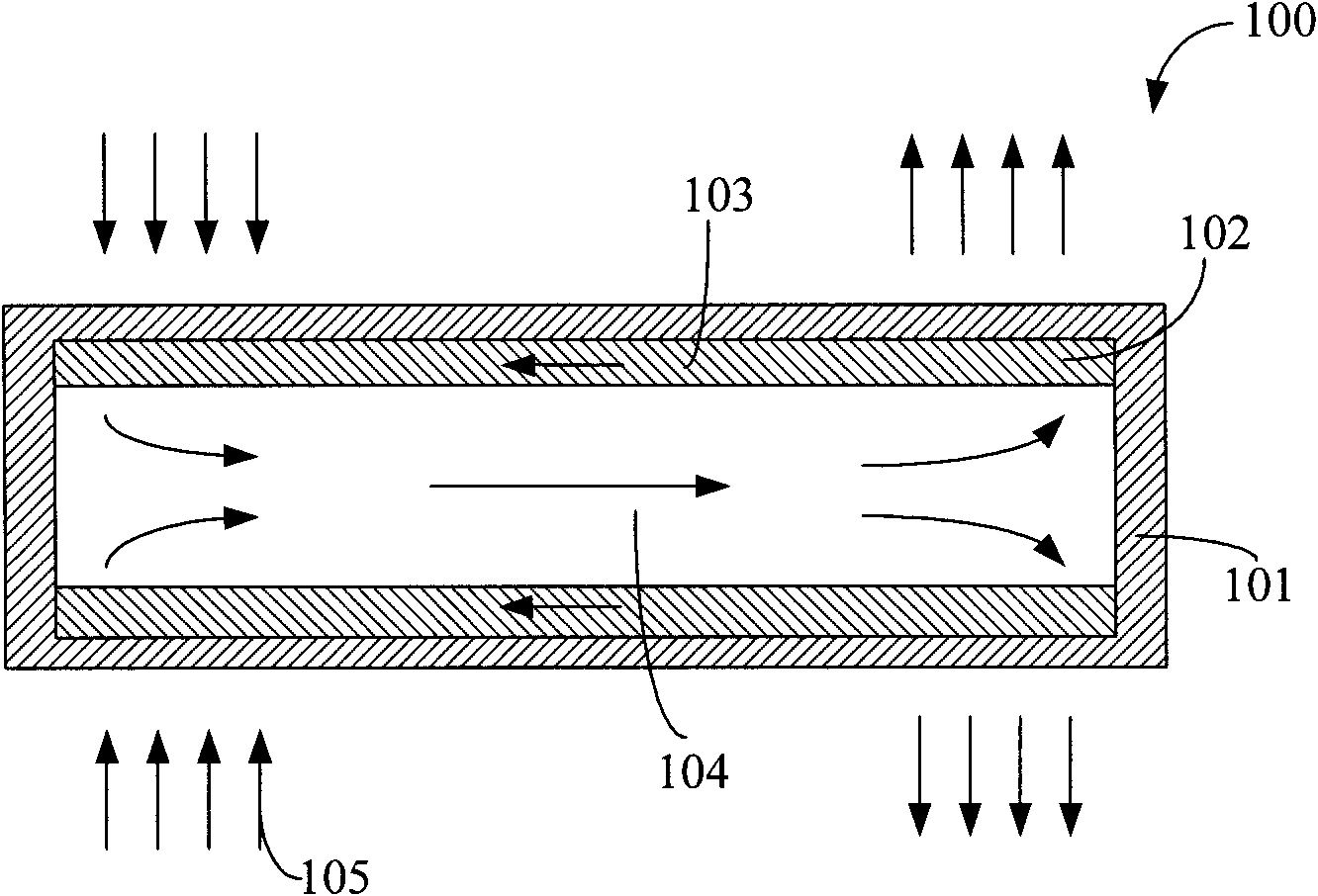

A heat pipe and pipe body technology, applied in the field of heat conduction, can solve the problems of low heat conduction efficiency of the heat pipe, and achieve the effects of increasing the volume, increasing the capillary force, and improving the return flow efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The designer found that for the capillary structure, the smaller the pores, the greater the capillary force generated by the capillary structure, and the larger the capillary force generated by the capillary structure, the larger the volume, the designer considered designing a heat pipe, which includes a larger The capillary structure with small volume and small pores can achieve high heat conduction efficiency.

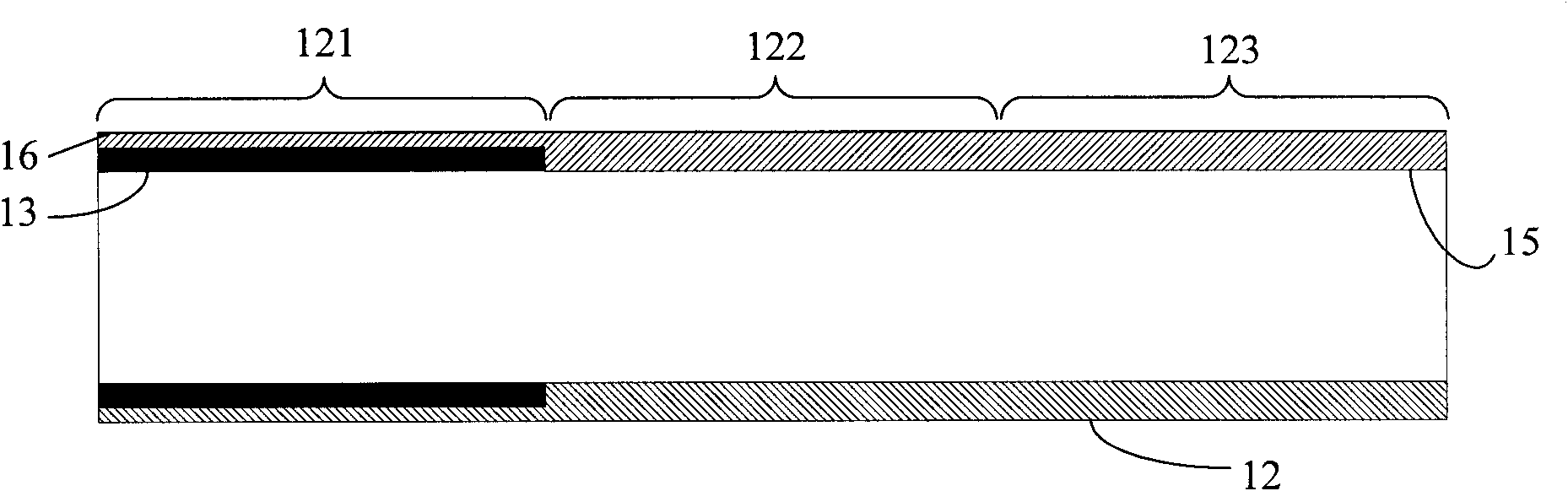

[0027] refer to figure 2 , shows a schematic diagram of an embodiment of the heat pipe of the present invention. The heat pipe includes: a tube body 12, the tube body 12 includes an evaporation part 121 and a condensation part 123 located at both ends of the tube body; a working medium filled in the tube body; and a working medium from the evaporation part to the condensation part. media channel.

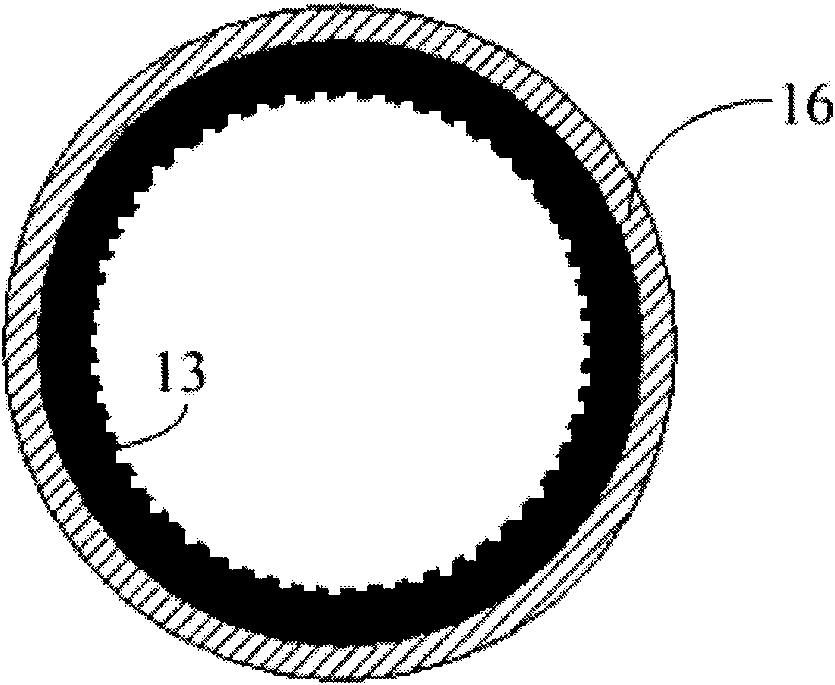

[0028] The tube body 12 is a hollow cylindrical body, and the tube body 12 is usually made of a material with good thermal conductivity, such as metal materials ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com