Non-contact power supply device for rotating mechanism

A rotating mechanism, non-contact technology, applied in the direction of circuit devices, electrical components, electromagnetic wave systems, etc., can solve the problems of speed limitation, large energy loss, unsuitable for high-power, high-efficiency workplaces, etc., to achieve improved induction efficiency, Meet the effect of high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in combination with specific embodiments.

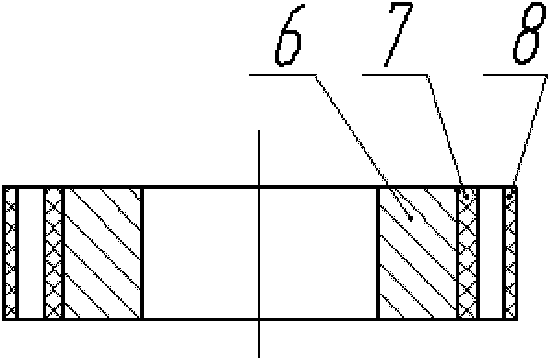

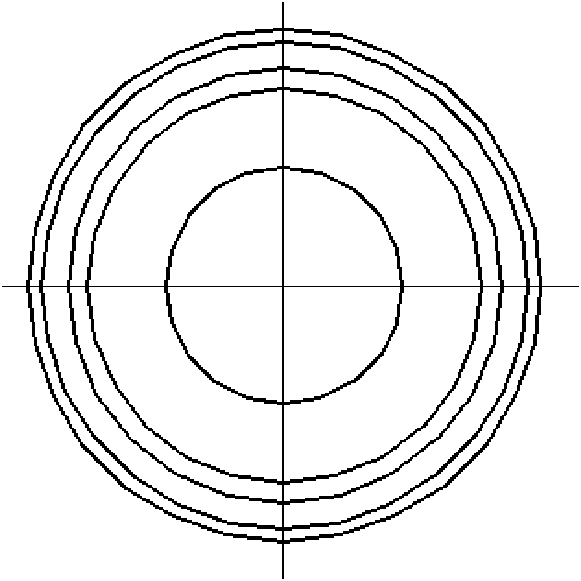

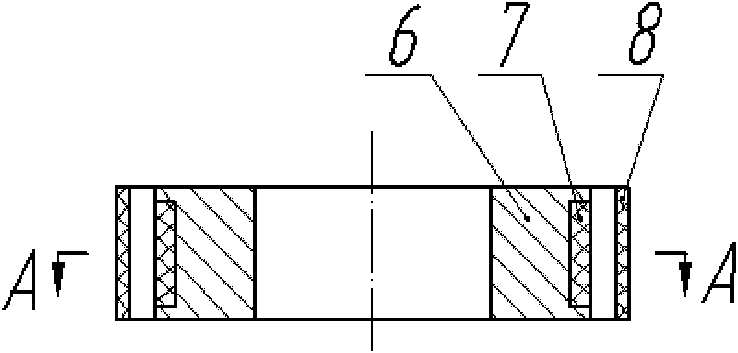

[0035] A non-contact power supply device for a rotating mechanism of the present invention includes a primary side and a secondary side, the primary side is composed of a primary side coil 8, and the secondary side is composed of a secondary side magnetic core 6 and a secondary side magnetic core The secondary side coil 7 on 6 constitutes; the secondary side is arranged at the center of the main side, and the main side and the secondary side are arranged on the same axis; in the radial direction, the inner diameter of the main side is approximately It is larger than the outer diameter of the secondary side, so that there is a gap between the two in the radial direction, and the gap should be minimized without affecting the rotation of the secondary side and the rotating mechanism.

[0036] The main side (fixed ring) is stationary, and the secondary side (moving ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com