Substrate holding member, substrate processing apparatus, and substrate processing method

A substrate holding and substrate technology, applied in electrical components, semiconductor/solid-state device manufacturing, ion implantation and plating, etc., can solve the problems of chip outer edge damage, short circuit, chip breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

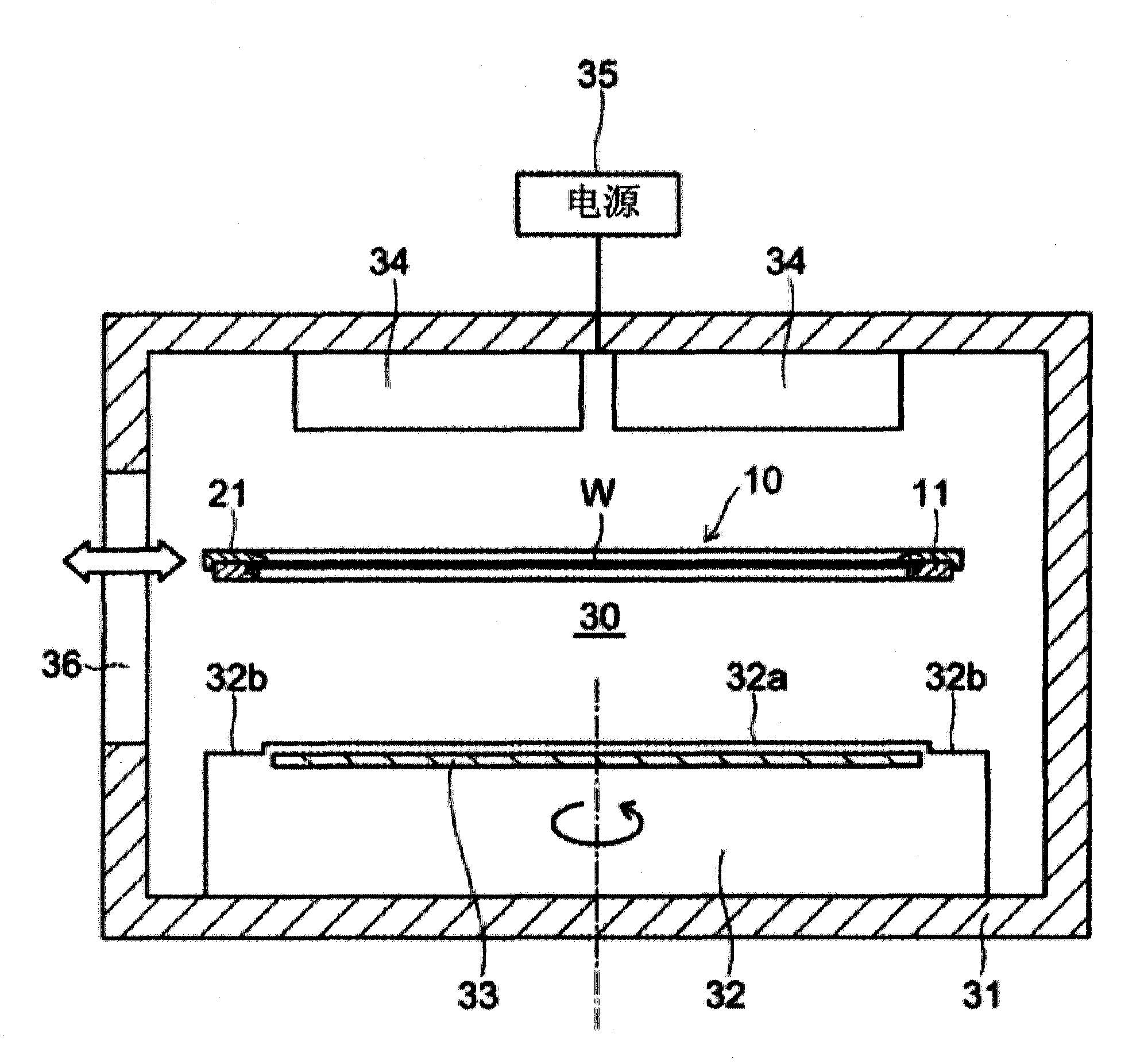

[0017] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In the embodiment of the present invention, a specific example in which, for example, a semiconductor wafer is used as a substrate to be processed and sputtering film formation is performed on the semiconductor wafer will be described.

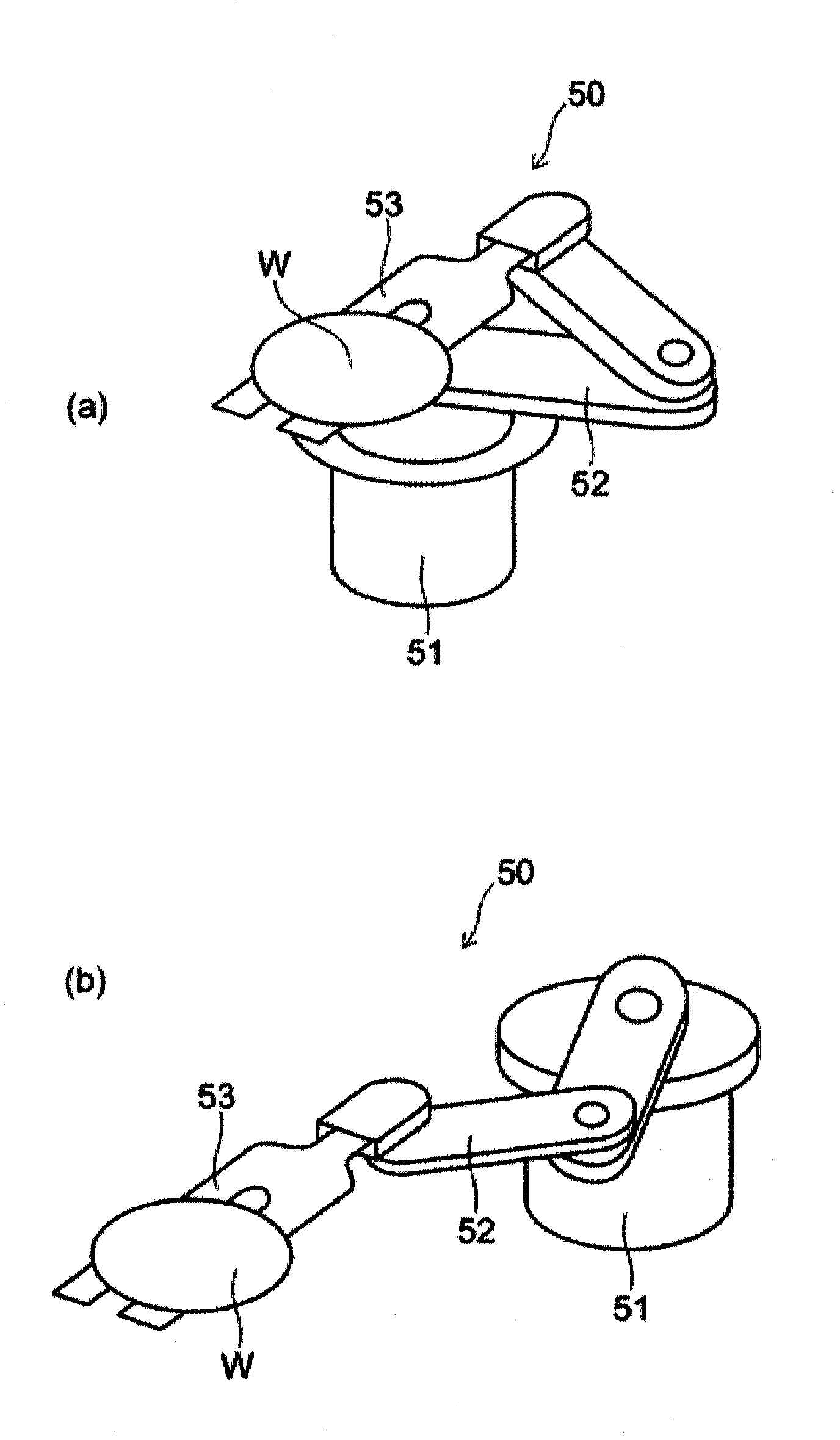

[0018] In the embodiment, the semiconductor wafer to be processed is very thin, for example, has a thickness of 10 to 100 μm, more specifically, about 50 μm. In the present embodiment, the thin semiconductor wafer is carried into and out of the processing chamber while being held by the holding member.

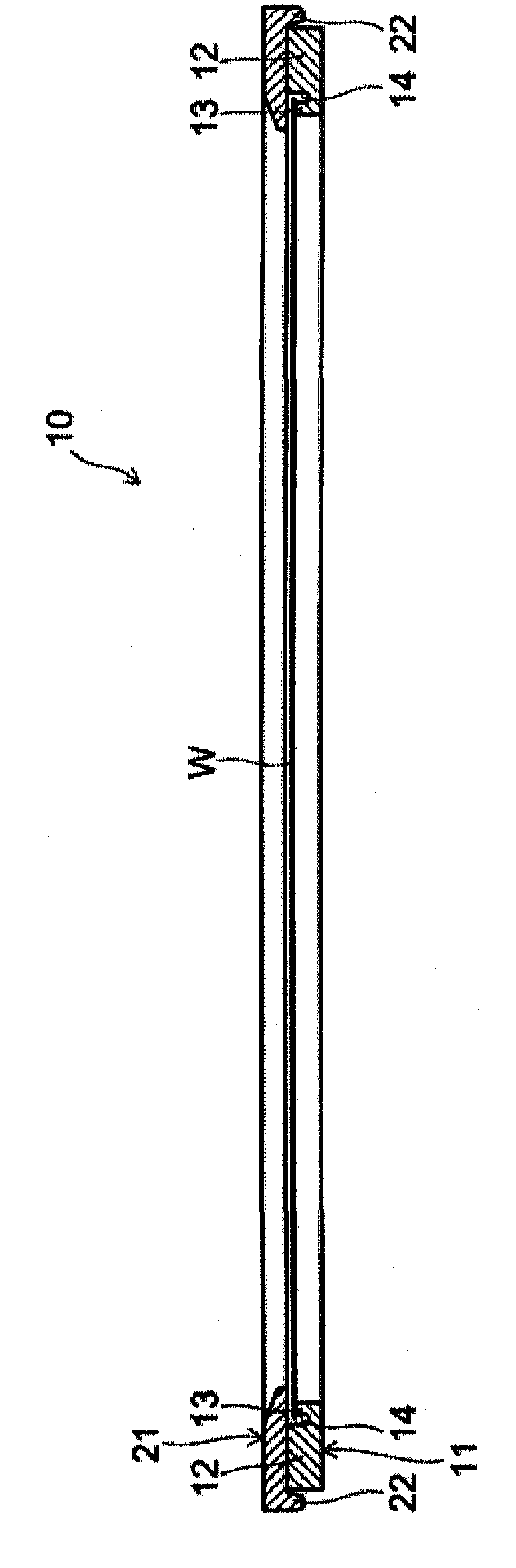

[0019] figure 1 A schematic cross-sectional view of the holding member 10 is shown. Moreover, in figure 1 2 also shows the semiconductor wafer W held by the holding member 10 at the same time.

[0020] The holding member 10 is composed of an annular holder 11 and a similarly annular mask 21 . The above-mentioned holder 11 and mask 21...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com