Novel method for making savory sauce duck

A production method and sauce duck technology, applied in the field of sauce brine products, can solve the problems of insufficient bite strength, soft taste, unsuitable for large-scale production in factories, etc., and achieve the effect of avoiding salt, strong sauce flavor and tight organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

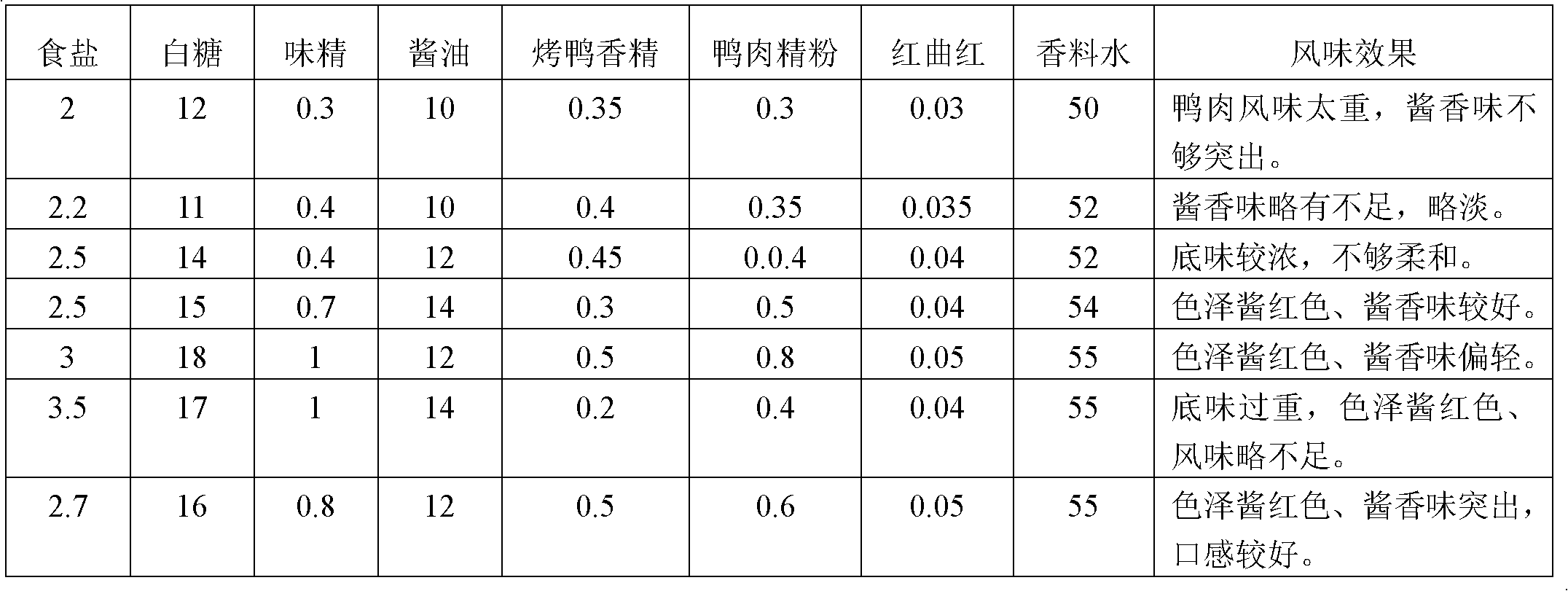

Examples

Embodiment 1

[0028] 1. Acceptance of raw and auxiliary materials: use lean cherry valley ducks with a lean meat rate of more than 70% and a breast meat rate of 23.5% to 24.5%, with a weight between 1.5 and 1.6KG, no congestion, white skin, and claws removed.

[0029] 2. Thawing: Use natural thawing, the room temperature is about 15°C. Thaw to the central temperature of -2 ~ 0 ℃.

[0030] 3. Pretreatment: Remove the anus, tail fat glands, trachea, esophagus, rough hair roots and impurities of the duck, clean the mouth and nostrils of the duck head, wash it in water, squeeze out the nasal mucus, and clean the surface and inner cavity of the duck body with clean water , hang to dry.

[0031] 4. Injection

[0032] ①. Spice water boiling: 0.25kg star anise, 0.15kg cinnamon, 0.06kg clove, 0.12kg cumin, 0.15kg tangerine peel, 0.2kg pepper, 5kg dried chili, water: 50kg, after boiling, keep it on low heat for 2 hours, boil Make spiced water. Put it into a 0-4°C storage and cool it down to a wat...

Embodiment 2

[0042] 1. Acceptance of raw and auxiliary materials: use lean cherry valley ducks with a lean meat rate of more than 70% and a breast meat rate of 23.5% to 24.5%, with a weight between 1.5 and 1.6KG, no congestion, white skin, and claws removed.

[0043] 2. Thawing: Use natural thawing, the room temperature is about 15°C. Thaw to the central temperature of -2 ~ 0 ℃.

[0044] 3. Pretreatment: Remove the anus, tail fat gland, trachea, esophagus, coarse hair roots and impurities. The duck head should be cleaned in the mouth and nostrils, washed in water, and the nose should be squeezed out. The surface and inner cavity of the duck body should be cleaned with clean water and hung Hang to dry.

[0045] 4. Injection

[0046] ①. Spice water boiling: 0.25kg star anise, 0.15kg cinnamon, 0.06kg clove, 0.12kg cumin, 0.15kg tangerine peel, 0.2kg prickly ash, 5kg dried chili, water: 50kg, after boiling, keep on low heat for 1.5 hours, boil Make spiced water. Put it into a 0-4°C storage...

Embodiment 3

[0056] 1. Acceptance of raw and auxiliary materials: use lean cherry valley ducks with a lean meat rate of more than 70% and a breast meat rate of 23.5% to 24.5%, with a weight between 1.5 and 1.6KG, no congestion, white skin, and claws removed.

[0057] 2. Thawing: Use natural thawing, the room temperature is about 15°C. Thaw to the central temperature of -2 ~ 0 ℃.

[0058] 3. Pretreatment: Remove the anus, tail fat gland, trachea, esophagus, coarse hair roots and impurities. The duck head should be cleaned in the mouth and nostrils, washed in water, and the nose should be squeezed out. The surface and inner cavity of the duck body should be cleaned with clean water and hung Hang to dry.

[0059] 4. Injection

[0060] ①. Spice water boiling: 0.25kg star anise, 0.15kg cinnamon, 0.06kg clove, 0.12kg cumin, 0.15kg tangerine peel, 0.2kg prickly ash, 5kg dried chili, water: 50kg, after boiling, keep on low heat for 1.5 hours, boil Make spiced water. Put it into a 0-4°C storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com