Carbon fiber brassie body and forming method thereof

A technology for golf clubs and molding methods, which is applied to golf balls, golf clubs, rackets, etc., and can solve problems such as poor hitting effect, poor bending resistance and torsion resistance of the shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

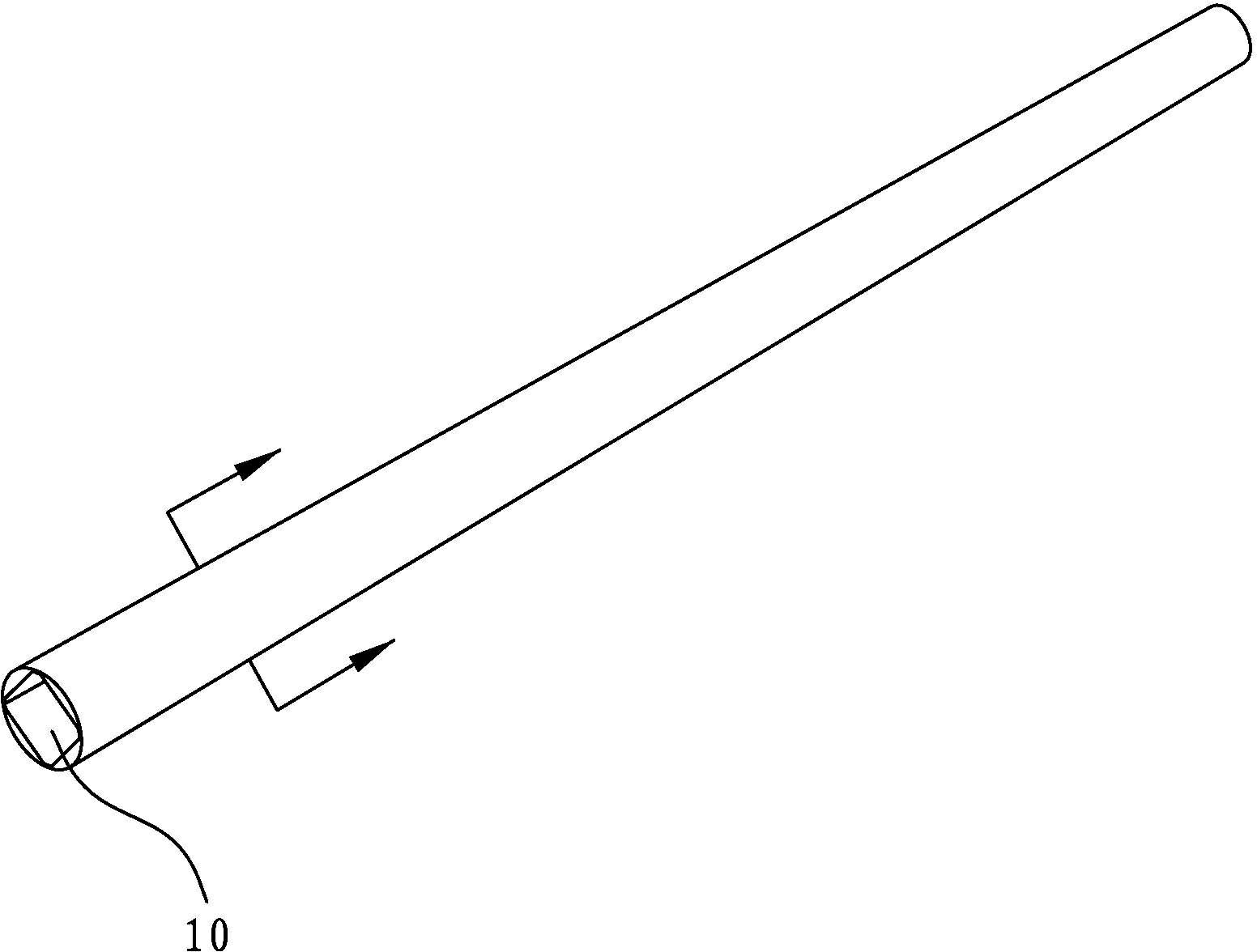

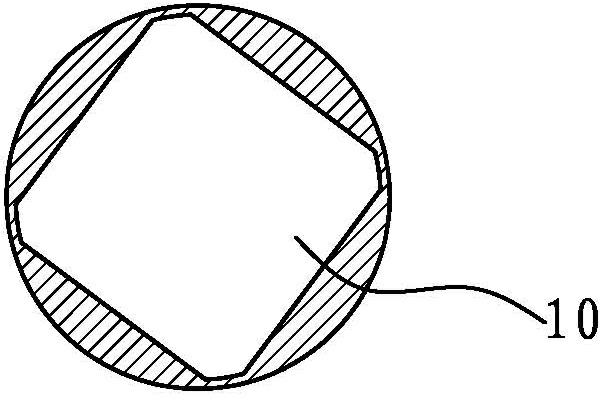

[0022] see figure 1 and figure 2 As shown, in the carbon fiber golf club shaft disclosed in the present invention, the central hole is a square hole 10, such as a rectangular hole or a square hole.

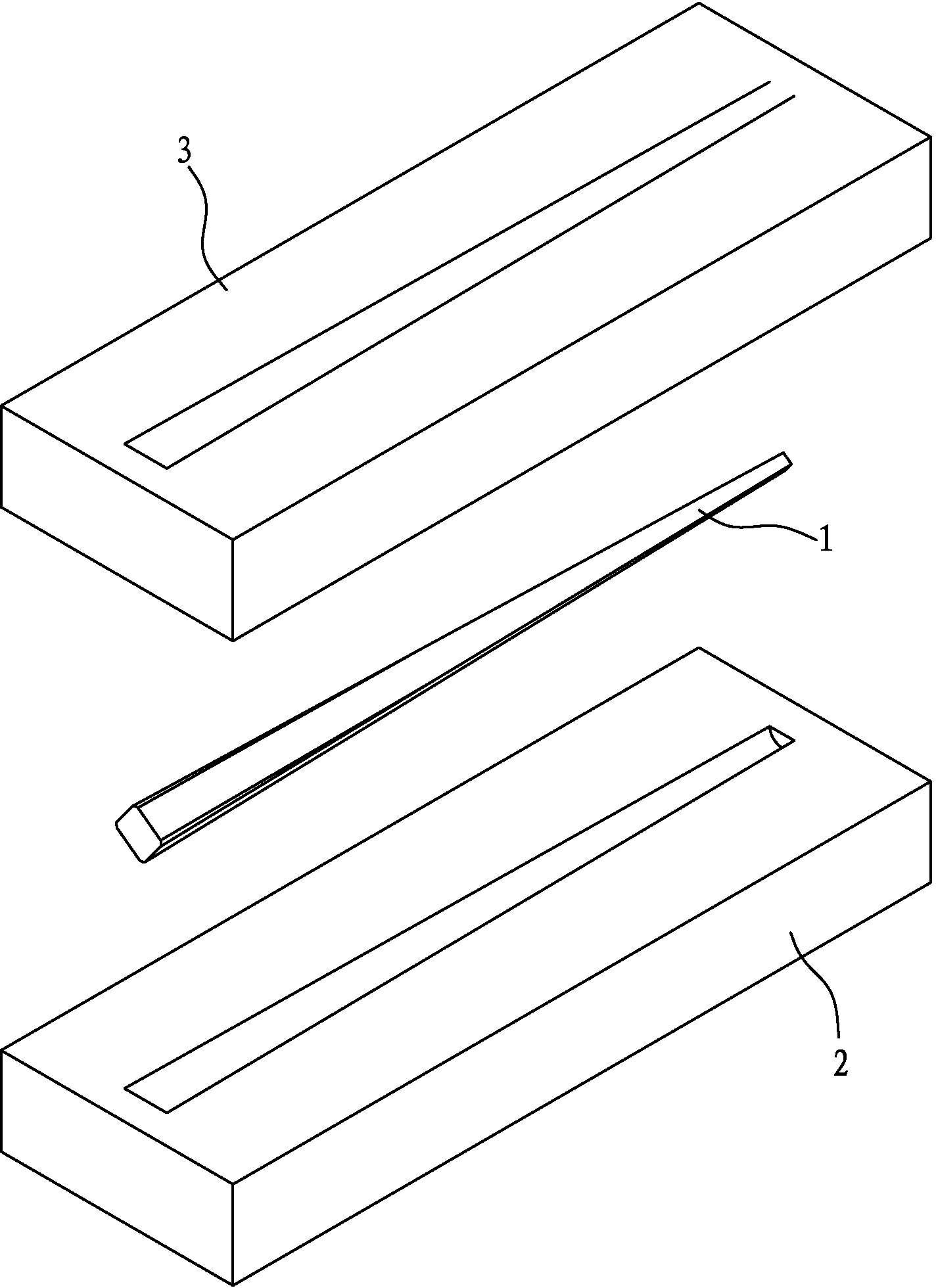

[0023] The molding method of the carbon fiber golf club shaft of the present invention is as follows: image 3 and Figure 4 shown:

[0024] First select a square mandrel 1, such as a rectangular mandrel (see image 3 ) or square mandrel; release agent and resin;

[0025] Next, the carbon fiber material 4 is wrapped on the mandrel 1 to form a round rod on the outside; specifically, the carbon fiber material 4 can be laid on each side of the square mandrel 1 layer by layer, and the carbon fiber material 4 is formed from the inside. It gradually becomes smaller layer by layer, so that the carbon fiber material 4 wraps the core rod 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com