Universal closing-up device for spherical surface of spinning conduit

A closing device and catheter technology, applied in the field of spinning closing devices, can solve the problems of long production preparation period, low production efficiency, inconvenient operation, etc., and achieve the effects of accurate and reliable closing positioning, low cost and simplified processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

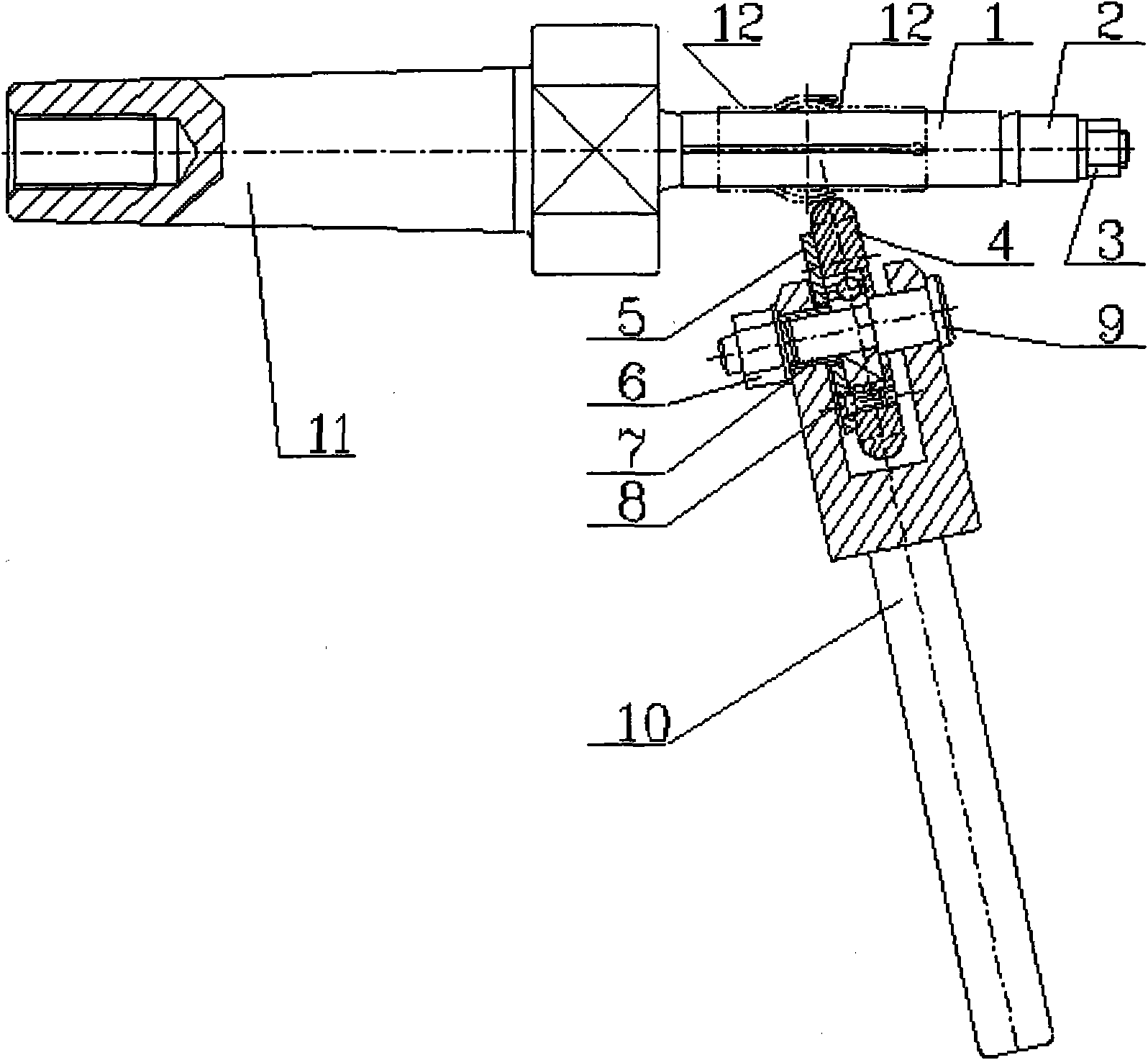

[0013] refer to figure 1 . The universal closing device for spinning the spherical surface of the catheter proposed by the present invention includes a positioning component connected to the main shaft of the lathe through a Morse taper and a spinning component fixed on the tool holder of the lathe. The positioning component is connected to the main shaft of the lathe through the Morse taper mandrel 11 for rotational movement, and the spinning component is fixed on the lathe tool rest and moves in the X and Y directions, so that the pressure of the rollers of the spinning component fixed on the lathe tool rest, Perform rapid spinning and closing forming on spherical conduit closing sleeve parts.

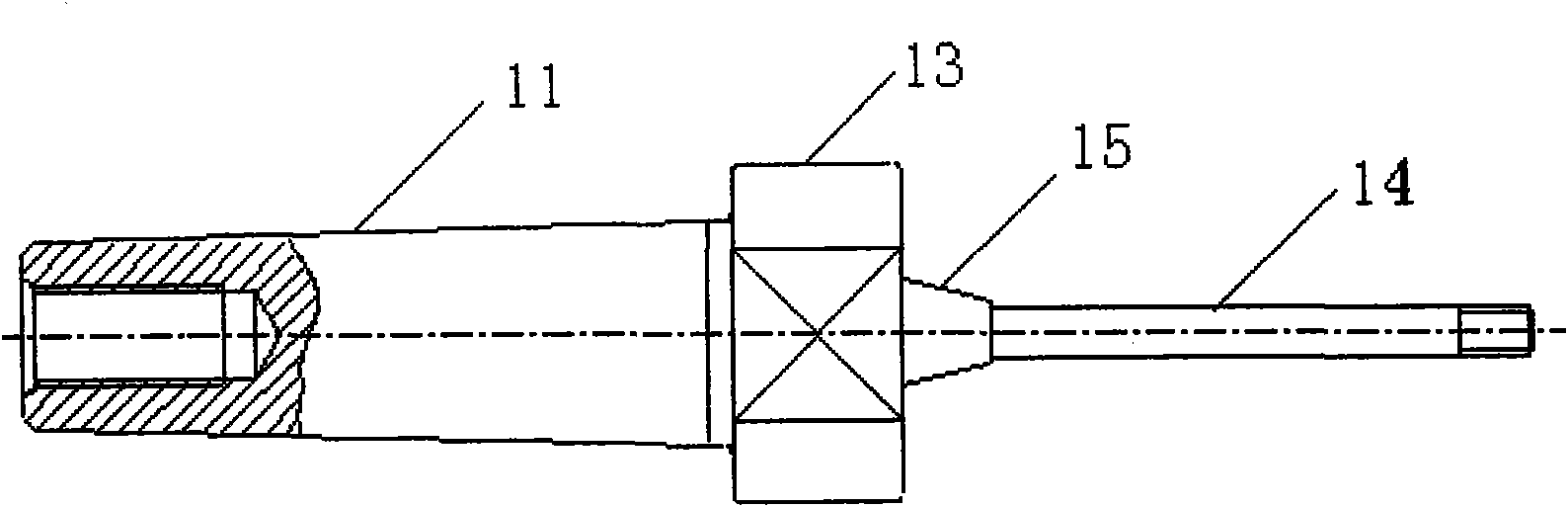

[0014] The positioning assembly includes a Morse taper mandrel 11 connected to the main shaft of the lathe for rotational movement and a mandrel 14 integrally connected with the end face of the front cylindrical step 13. The cone 15 of the taper hole is shaped on its free end to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com