Method for grinding concave surface of cam with concave surface

A technology of concave cam and concave surface, which is applied in the direction of abrasive belt grinder, etc., can solve the problem of complex cam shape and achieve the effect of high grinding precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

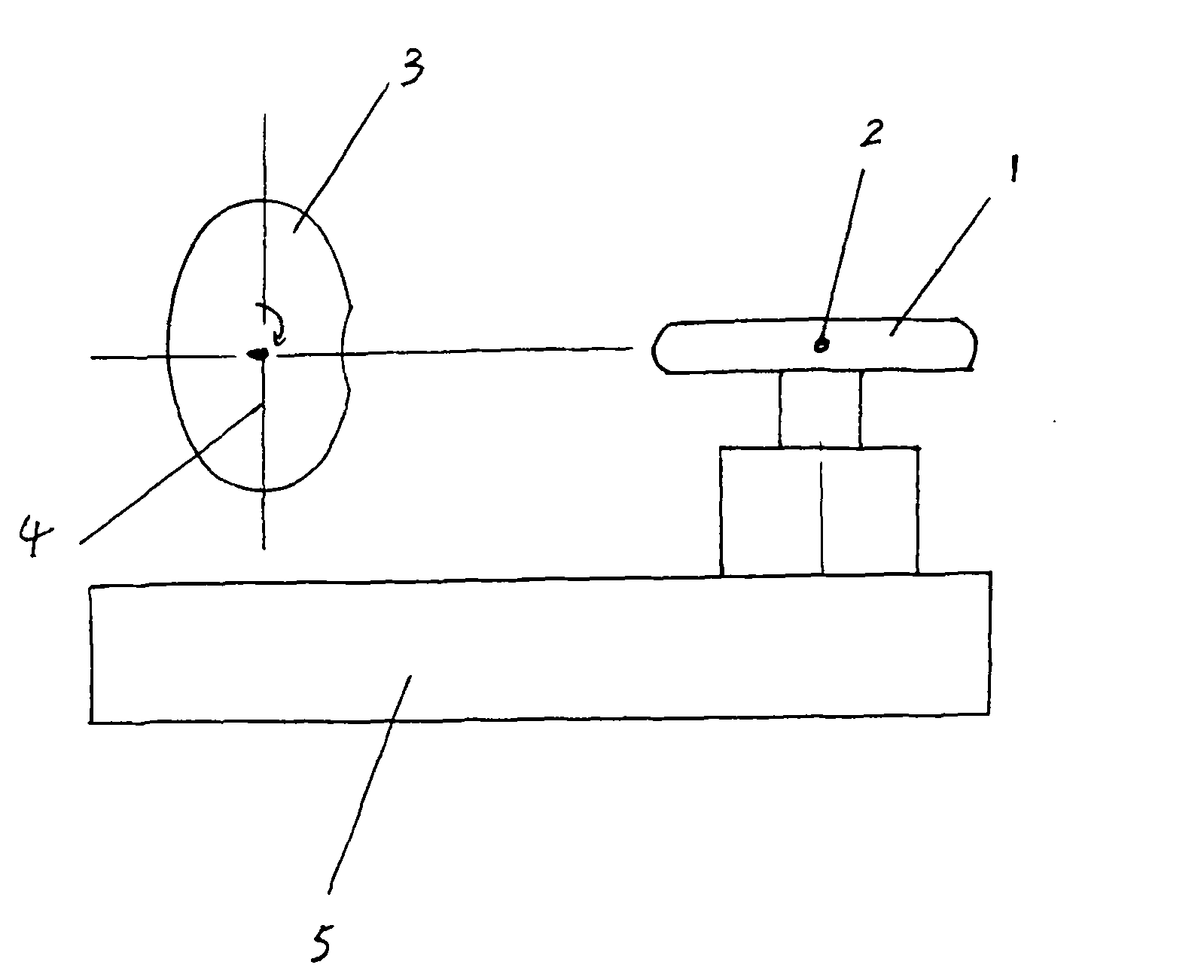

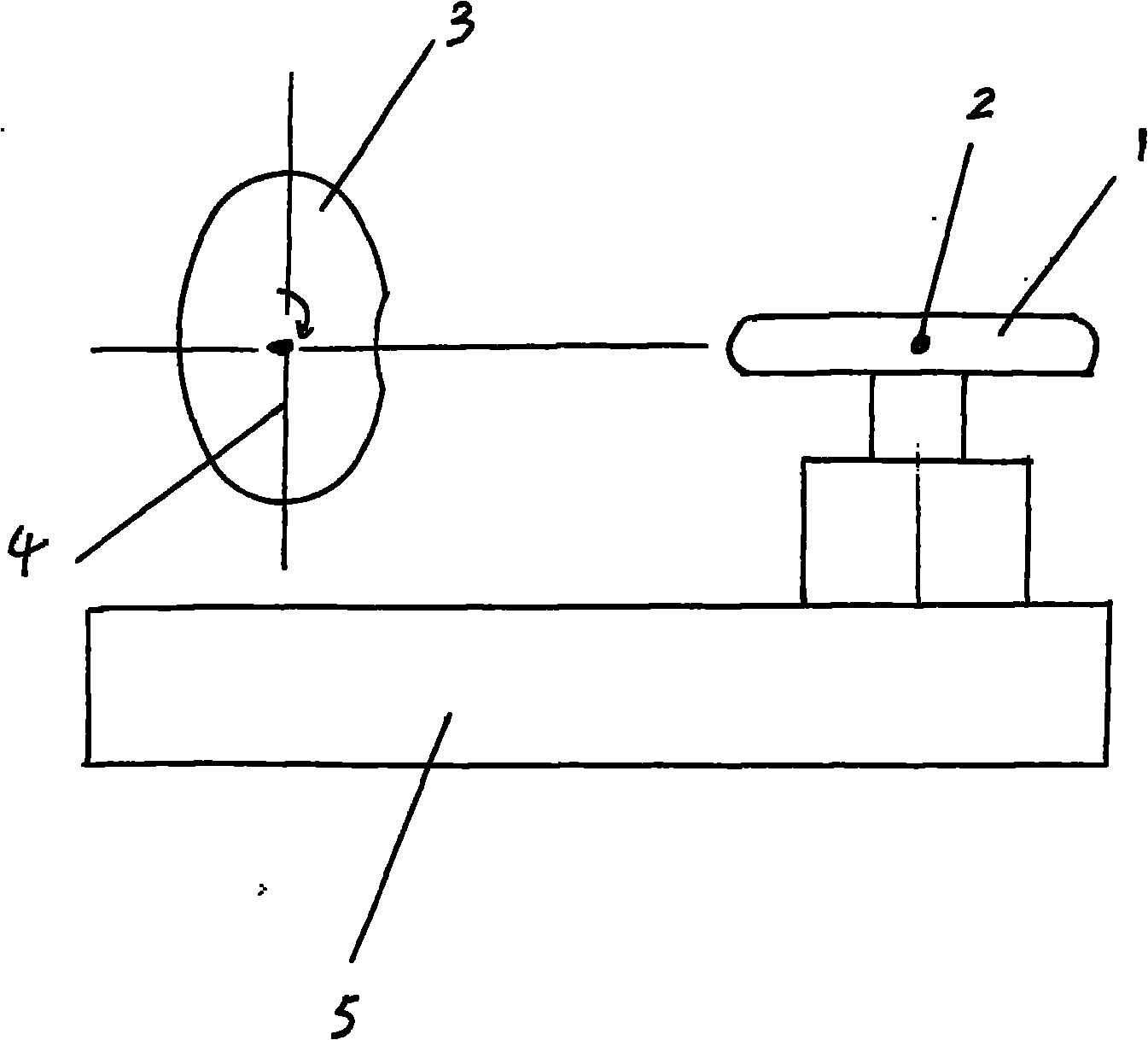

[0009] Such as figure 1 As shown, a grinding method for a concave surface with a concave-convex wheel, the rotation center line 2 of the grinding wheel 1 is set perpendicular to the rotation center line 4 of the cam 3, and the grinding wheel spindle is installed on the same side as the cam rotation center line and the grinding wheel rotation center. Lines are respectively perpendicular to the linear motion guide rail 5, moving the linear motion guide rail 5 to control the distance between the center of the grinding wheel and the center of the cam, and rotating the cam accordingly, the concave surface of the cam can be processed.

[0010] In the present invention, the cross section of the grinding wheel can be trimmed to be consistent with the shape of the cylindrical tappet and the relative position of the cam center. As long as the cam is rotated and the grinding wheel is moved to make the motion relationship between the two conform to the cam rotation angle-cylindrical tappet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com