Food and beverage outer package printed with temperature change ink pattern

A temperature-changing ink and outer packaging technology, applied in the field of outer packaging, food and beverage outer packaging, can solve problems such as intolerance of temperature-changing ink patterns, and achieve the effects of increasing practicability, strong adhesion and improving commodity value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

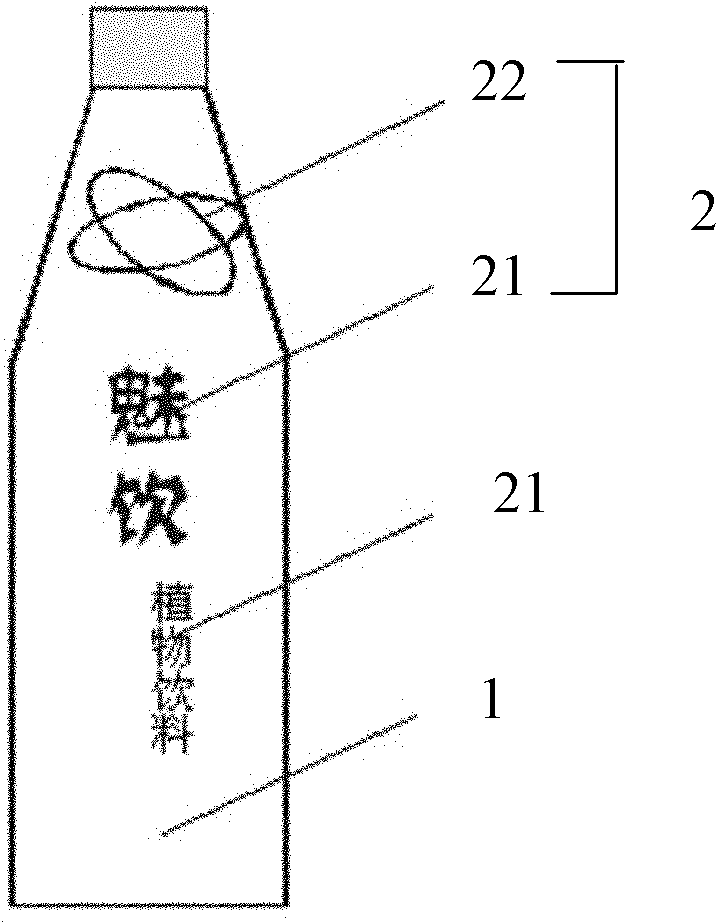

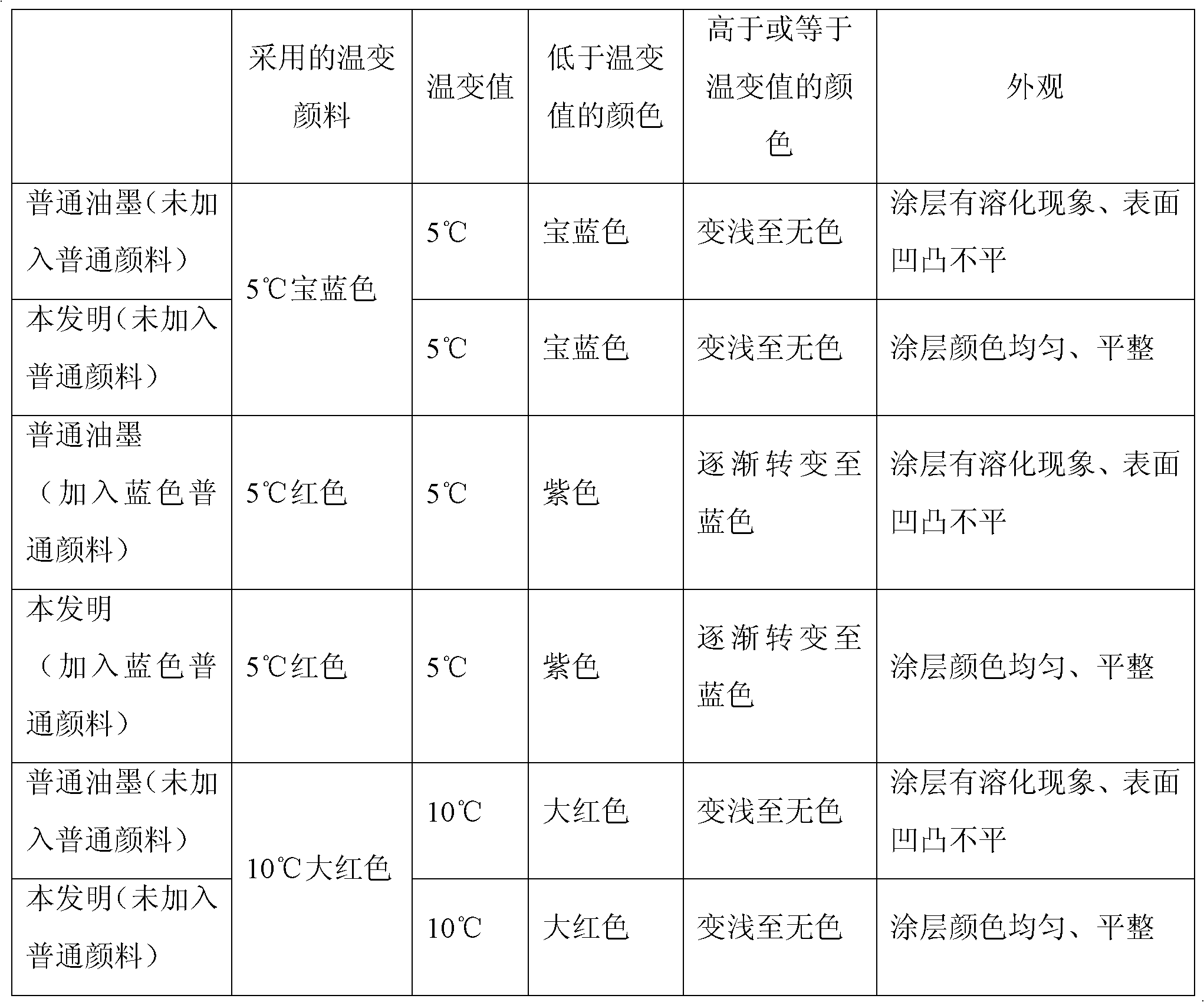

[0021] Embodiment 1, as figure 1 , 2 As shown, a food and beverage outer package includes a container 1 for containing food and beverage, and a temperature-changing ink coating 2 is provided on the outer wall of the container 1 . The container used in this embodiment is a glass container, and the visible part of the outer wall of the glass container is printed with a temperature-changing ink coating 2 . The temperature-changing ink coating 2 is independently selected as the text temperature-changing ink coating 21, and the text temperature-changing ink coating 21 is various text marks printed on the outer wall of the glass container with temperature-changing ink, such as: product name, Enterprise text trademarks, etc., the temperature-changing ink coating 2 can also be selected as a graphic temperature-changing ink coating 22. Graphical temperature-changing ink coating 22 is a variety of graphic signs printed on the outer wall of the glass container with temperature-changing...

Embodiment 2

[0047] Embodiment 2: as figure 1 , 2 As shown, the outer package of food and beverage includes a container 1 for containing food and beverage, and the outer wall of the container 1 is provided with a temperature-changing ink coating 2 . The container in this embodiment is a glass bottle, and at least one form of temperature-changing ink coating 2 among graphics and text is printed on the outer wall of the glass bottle, and the temperature-changing ink coating 2 is a text temperature-changing ink coating 21, The temperature-changing ink coating 2 described above may be a graphic temperature-changing ink coating 22 .

[0048] The temperature-changing ink for printing the temperature-changing ink coating of this embodiment is mainly made of the following raw materials in parts by weight: 57 epoxy resins, 15 temperature-changing pigments, 10 ordinary pigments, 16 m-xylylenediamine, and 2 palm oils. Among them, the temperature-changing pigment is 10°C red organic heat-sensitive t...

Embodiment 3

[0051] Embodiment 3: as figure 1 , 2 As shown, a food and beverage outer package includes a container 1 for containing food and beverage, and a temperature-changing ink coating 2 is provided on the outer wall of the container 1 . In addition to the glass container in Example 1, the temperature-changing ink coating 2 can also be printed on the ceramic container. The container of this embodiment is a ceramic tank, and at least one form of temperature-changing ink coating 2 among graphics and text is printed on the visible part of the outer wall of the ceramic tank. Specifically, the temperature-changing ink coating 2 includes text temperature The ink-changing coating 21 and the graphic temperature-varying ink coating 22 are composite temperature-varying ink coatings combining text and graphics. The visible part of the container refers to the visible part that can be seen except the bottom and inner wall after the container is placed normally.

[0052] The temperature-changing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com