Air pressure-type flushing water tank

A water tank flushing, air pressure technology, applied in flushing equipment with water tanks, water supply devices, buildings, etc., can solve problems such as failure of the water tank, no water in the water tank, rupture of the water tank, etc., to achieve water saving, better sealing performance, explosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

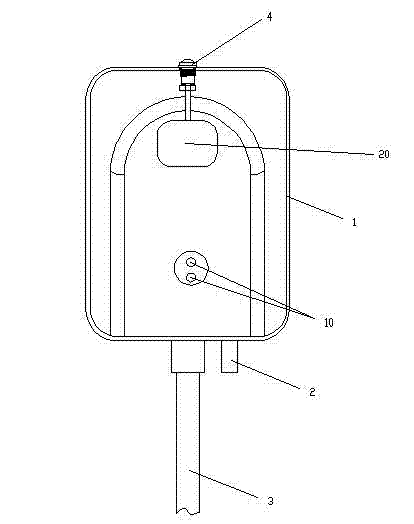

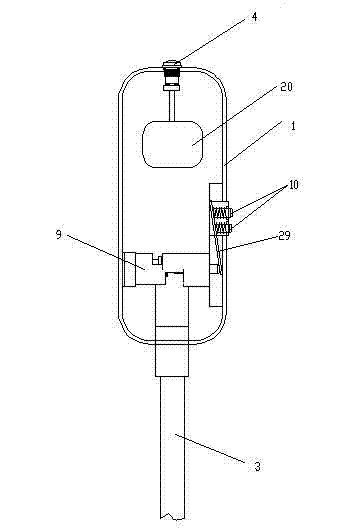

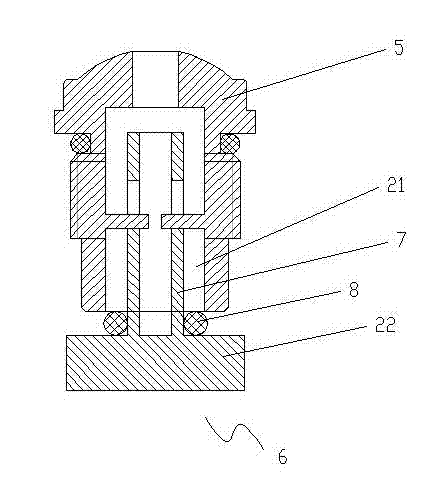

[0020] As described in Embodiment 1 of the present invention: as figure 1 , figure 2 As shown, a pneumatic flushing water tank includes a box body 1, and the box body 1 is provided with a cavity for holding water, and the box body 1 is provided with a water inlet pipe 2 and a water outlet pipe 3 communicating with the cavity, wherein the aforementioned The top of the box body 1 is provided with an intake and exhaust valve 4; image 3 As shown, the intake and exhaust valve 4 is composed of a fixed hole seat 5 passing through the top of the box body 1 and sealingly combined with the box body 1. The fixed hole seat 5 is provided with an air inlet and outlet channel 21 and A movable piston rod assembly 6 is arranged to cooperate with the air inlet and outlet channels; The lower second sealing ring 8 is composed of a floating ball 20 connected to the bottom of the piston rod 7, and the bottom of the piston rod 7 is a round block 22 that is larger than the hole diameter of the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com