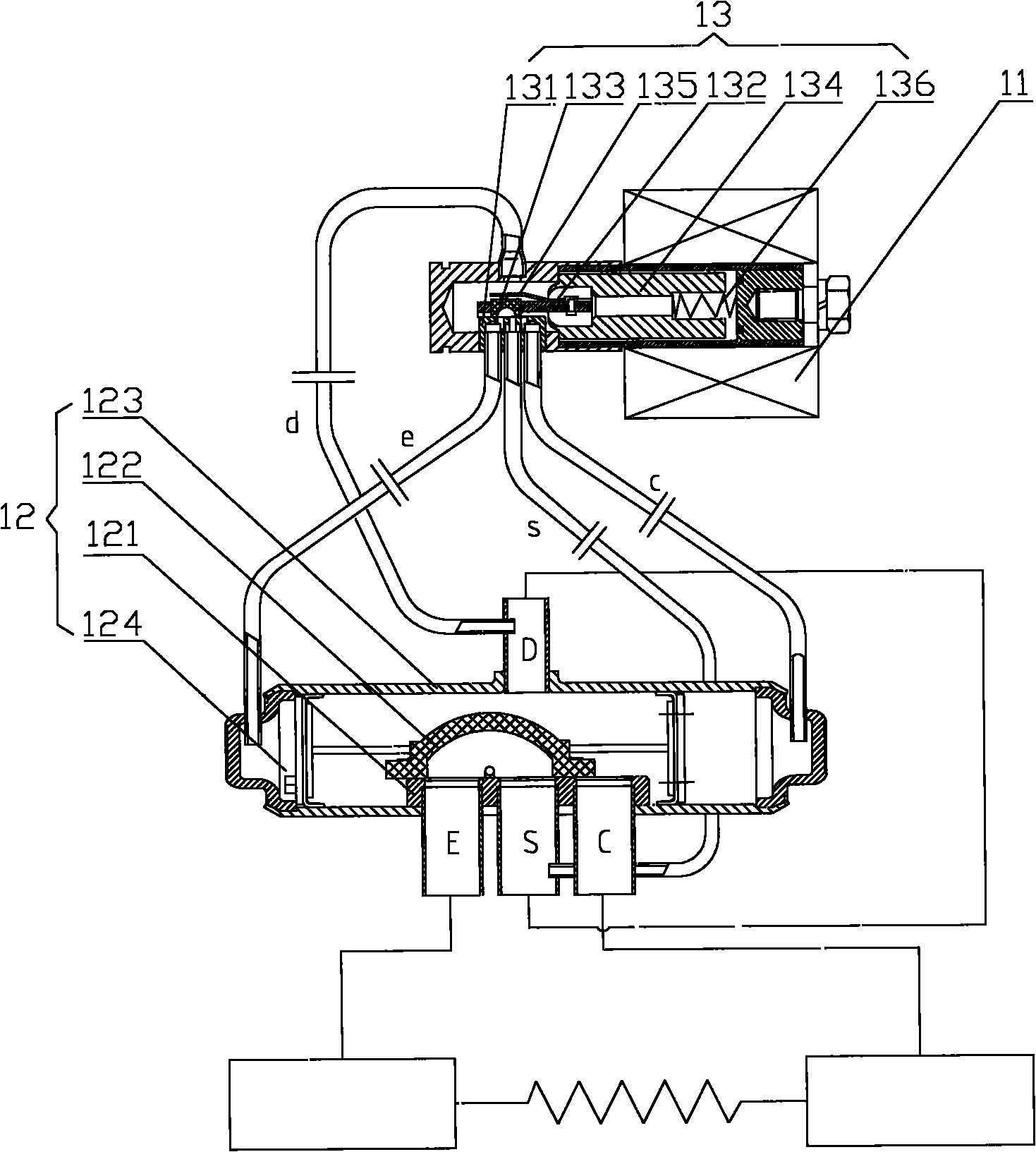

Reversing valve and dragging frame component thereof

A technology of drag frame and reversing valve, which is applied to engine components, valve details, multi-way valves, etc., can solve problems such as looseness of the crimping part between the drag frame 132 and the core iron 134, product failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The core of the present invention is to provide a drag frame assembly, the drag frame body and the core iron can be reliably connected, and when the two are fixedly connected, they have high connection and fixing reliability, thereby improving the operation of the reversing valve. reliability. Another core of the present invention is to provide a reversing valve comprising the above drag frame assembly.

[0034]In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

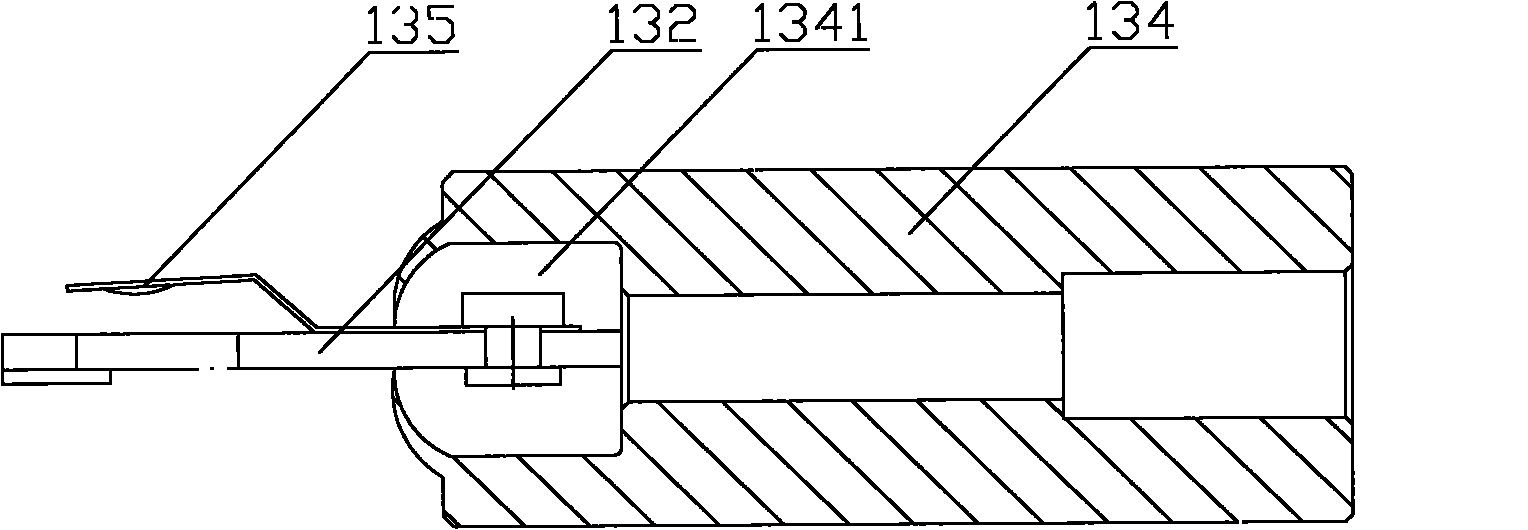

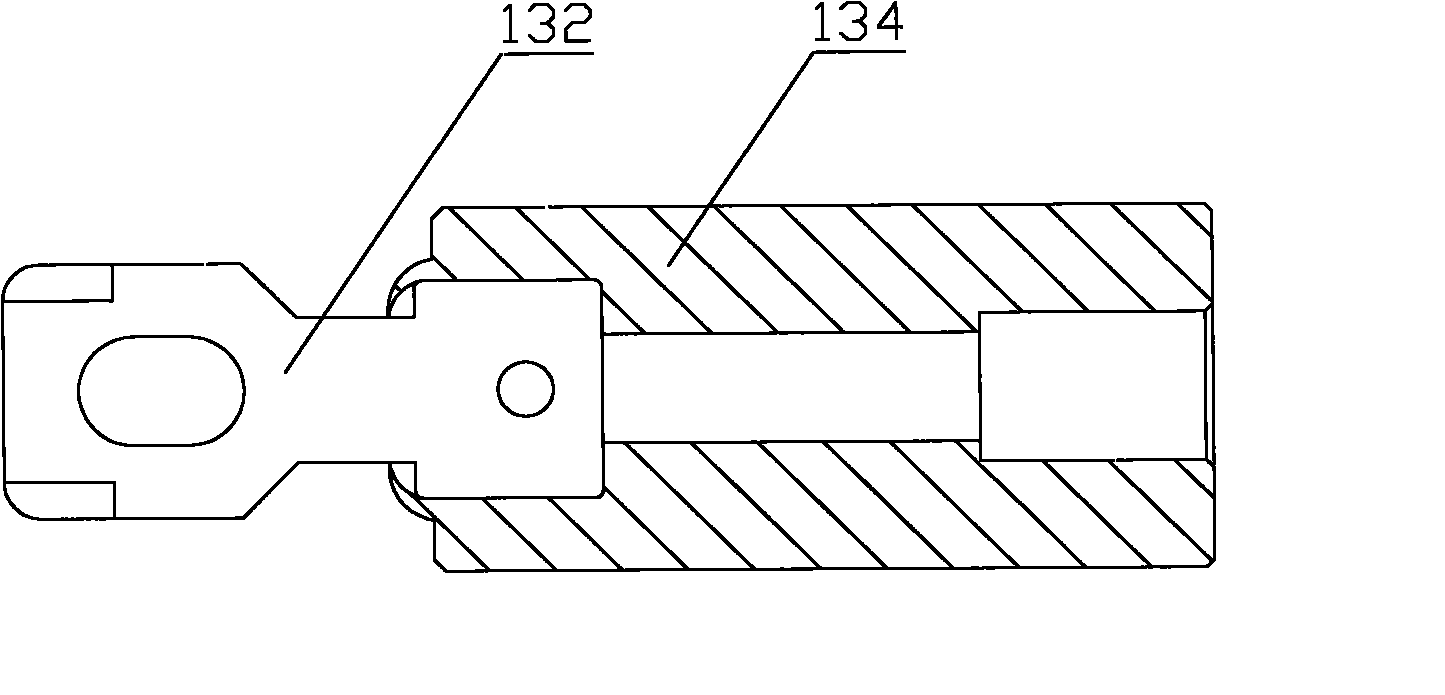

[0035] Please refer to Figure 4 with Figure 5 , Figure 4 It is a schematic cross-sectional view of the front view direction when the drag frame assembly and the core iron are in the assembled state provided by the first specific embodiment of the present invention; Figure 5 for Figure 4 Schematic diagram ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com