Device and method for detecting light condensation efficiency of condensing lens

A detection device and concentrating mirror technology, applied in the field of concentrating mirrors, can solve problems such as the gap in concentrating mirror light collection efficiency, uneven distribution of light energy, and uneven energy distribution, and achieve the effects of excellent construction cost, uniform distribution, and stable energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

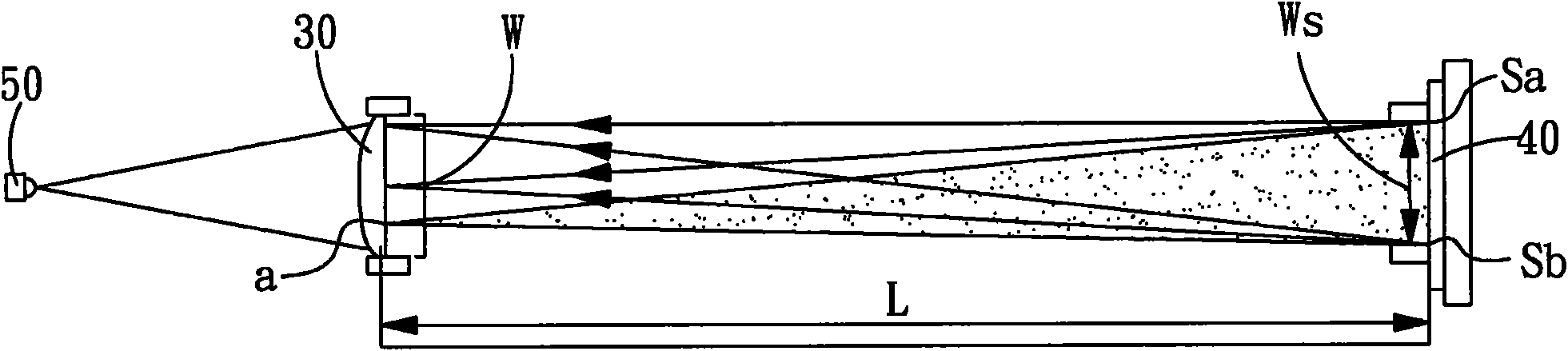

[0042] see Figure 3A and Figure 3B The parallel light beams of the simulated artificial solar light source in the detection method of the light collection efficiency of the concentrating lens of the present invention are provided by a stable and uniform planar light source 40 . In order to form a parallel light beam to test the condenser lens 30 to be tested, the distance between the plane light source 40 and the condenser lens 30 to be tested and the aperture diameter of the plane light source 40 need to be controlled.

[0043] Such as Figure 3A As shown, the uniform light emitted on the surface of the planar light source 40 has a large distribution angle, but when increasing the distance (L) between the planar light source 40 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com