Portable liquid sampling box

A portable, sampling box technology, applied in sampling devices and other directions, can solve problems such as increased work cost, lack of sealing, and reduced work efficiency, and achieve the effects of preventing air pollution, strong shock resistance, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

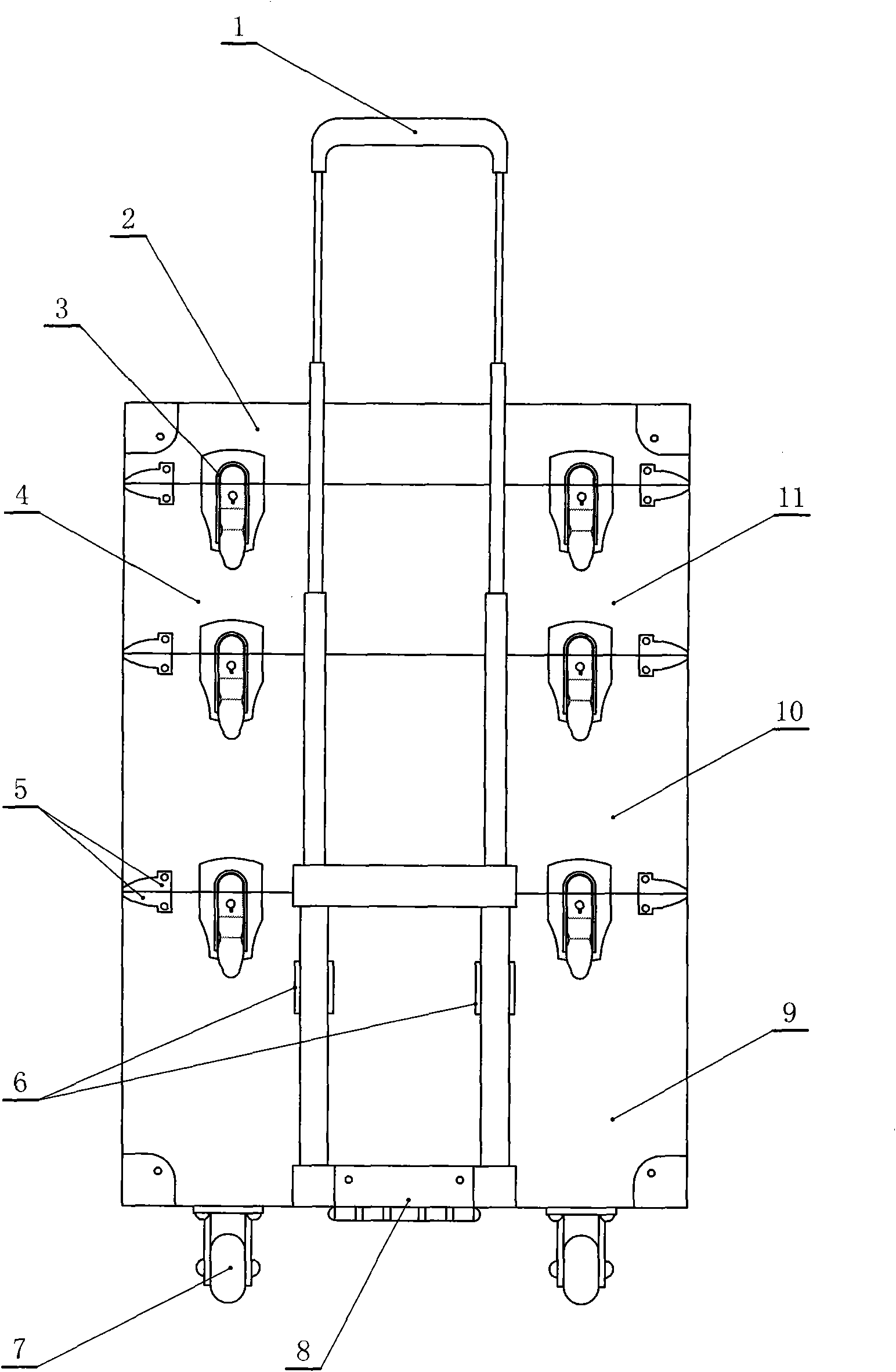

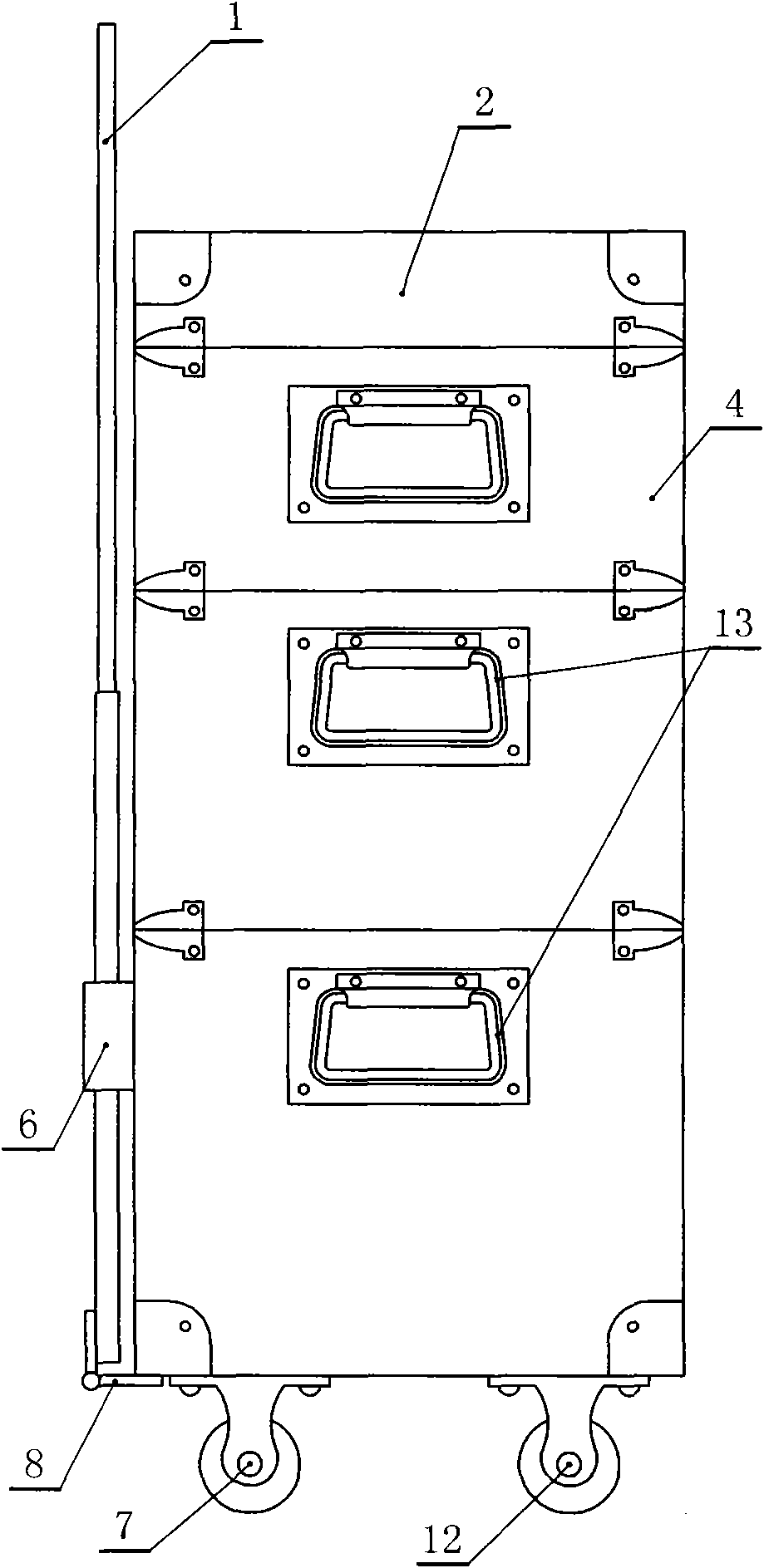

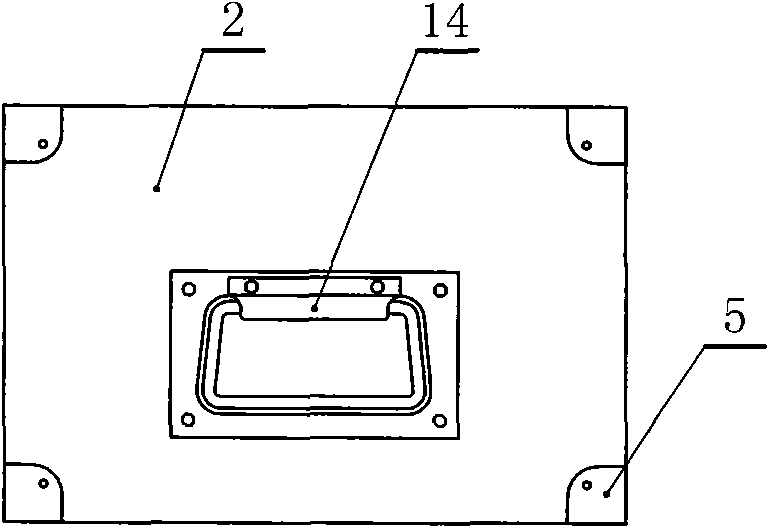

[0032] A portable liquid sampling box such as Figure 1 to Figure 4 Shown, comprise box body 4, box body 4 is provided with box cover 2 above, and box body 4 is provided with circular groove bucket 16, as Figure 8 As shown, a spring 17 is connected to the inner bottom wall of the round groove barrel 16, and a supporting plate 18 is connected to the upper end of the spring 17; The inside of the casing 4 is divided into a plurality of container tanks, and the circular tank bucket 16 is positioned in the container container, and the casing 4 includes a small bottle case 10 and a large bottle case 11 (see Figure 5 with Image 6 ); Described casing 4 includes toolbox 9, as Figure 7 As shown, the tool box 9 is divided into a funnel area 20, a large tool area 21 and a small tool area 22, and an iron box 19 is provided in the funnel area 20; a buffer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com