High-power induction charging converter of electric vehicle and control method thereof

A technology for electric vehicles and inductive charging, applied in electric vehicles, AC power input is converted into AC power output, current collectors, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

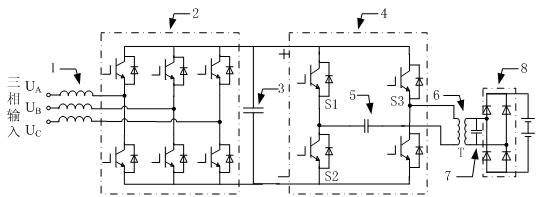

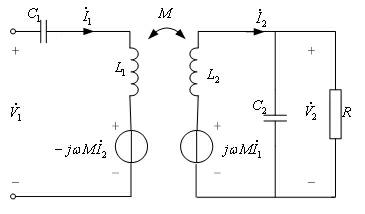

[0027] The high-power electric vehicle inductive charging converter device proposed by the present invention adopts the bridge rectification topology structure of six full-control switches in three phases, the high-frequency inverter topology of the single-phase full-bridge inverter circuit, and the primary side series compensation of loosely coupled transformers , The topology structure of secondary side parallel compensation. Each phase of the three-phase rectifier circuit is connected to a reactor on the AC side, and the DC side is connected to a DC energy storage capacitor; the inverter circuit is a full-bridge inverter circuit; the transformer adopts a loosely coupled transformer with separated primary and secondary sides, and the air gap of the transformer is long , the coupling coefficient is less than 0.5; the inductive coupling circuit series compensation capacitor is connected to the primary side of the loosely coupled transformer, and the secondary side is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com