Non-contact ultrasonic motor of bowl-type traveling wave mode ball rotors

A non-contact, ultrasonic motor technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of non-contact transmission of spherical bearing mechanism, etc., Achieve compact structure, high processing and assembly, easy installation and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The structure and working principle of the present invention will be described in detail below with reference to the drawings and specific embodiments.

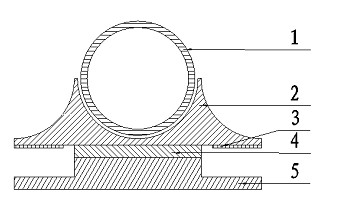

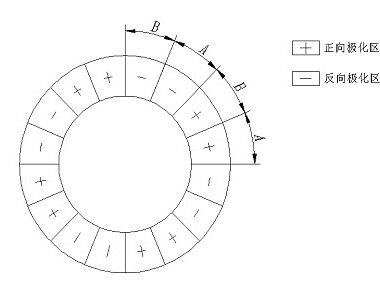

[0015] A bowl type traveling wave type ball rotor non-contact ultrasonic motor, characterized in that it includes a spherical rotor 1, a bowl type stator 2, an annular piezoelectric ceramic 3, an elastic pad 4 and a support device 5, wherein the spherical rotor 2 is located in the bowl type In the cavity of the stator 2; the annular piezoelectric ceramic 3 is located on the lower end surface of the bowl-shaped stator 2; the elastic pad 4 is located on the lower end surface of the bowl-shaped stator 2; the supporting device 5 is located on the bottom surface of the elastic pad 4. The annular piezoelectric ceramic 3 adopts the method of equal division and division;

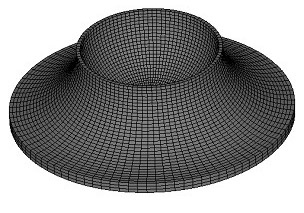

[0016] The driving end face of the stator is a bowl-shaped cavity, which is used to drive a spherical rotor with the same radius;

[0017] The bowl-type st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com