Web-fed presses with single-width folders for multiple-width belts

A technology of printing presses and webs, applied in the field of rotary web printing machines, which can solve the problems of inflexibility, changes in belt width, and impossibility, etc., and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

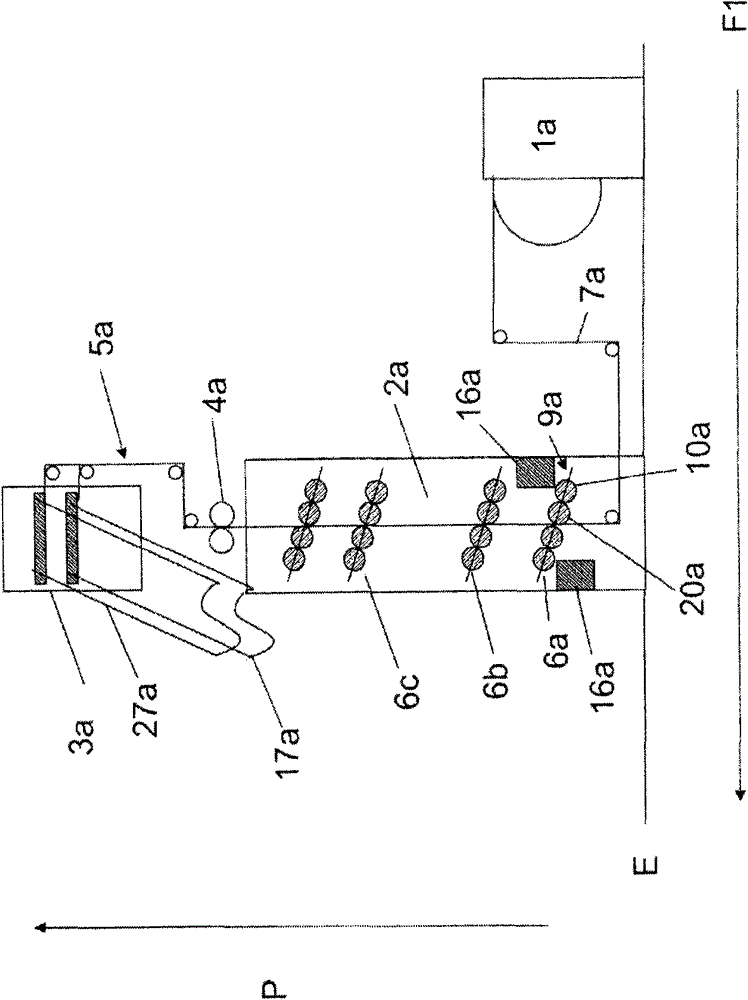

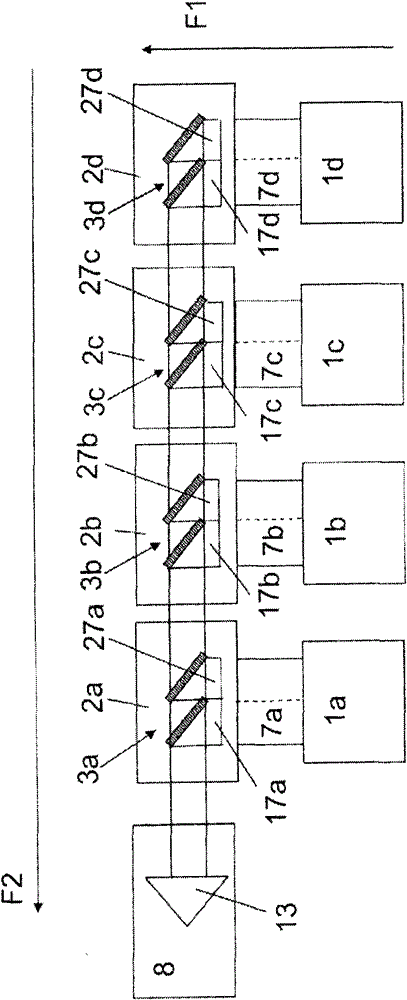

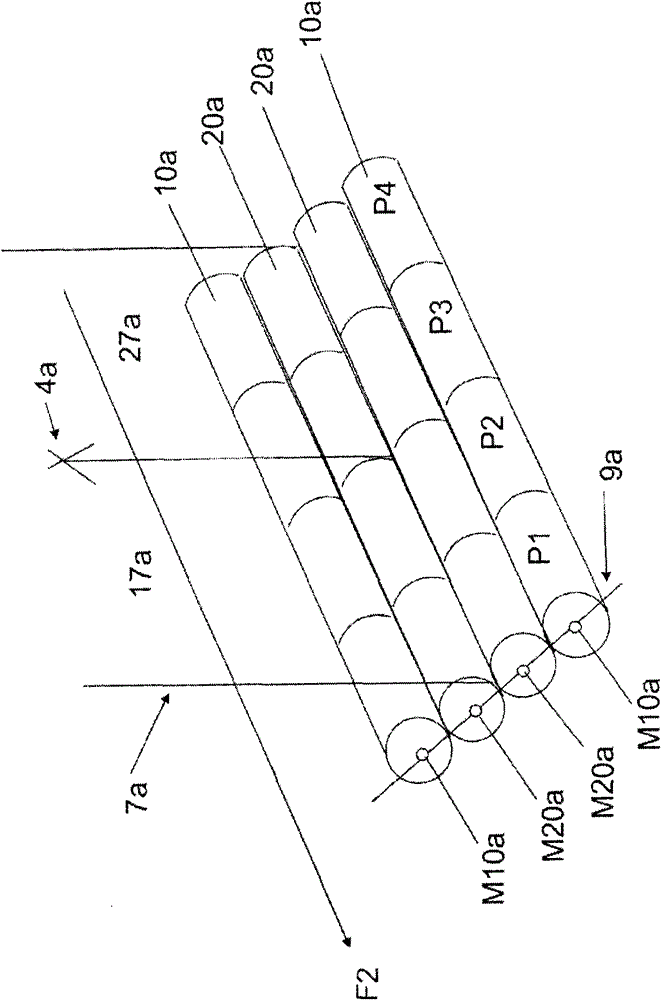

[0055] figure 1 and 2 as well as Figure 4 and 5Respectively shows a rotary web printing machine with a web changer 1a, 1b, 1c, 1d, a printing tower 2a, 2b, 2c, 2d with a plurality of printing units 6a, 6b, 6c, 6d, a belt diverter 3a , 3b, 3c, 3d and folding machine 8, wherein, belt steering device 3a, 3b, 3c, 3d can make sub-band 17a, 17b, 17c, 17d, 27a, 27b, 27c, 27d, 37a from printing tower 2a, 2b, 2c, 2d are turned by 90° towards the folder 8 . The belt deflectors 3a, 3b, 3c, 3d are arranged in a direction P perpendicular to the mounting plane E above the printing towers 2a, 2b, 2c, 2d. Folder 8 is designed as a single-width folder, as Figure 13 As shown, that is to say, it can process the paper strip 7a or sub-band 17a, 17b, 17c, 17d, 27a, 27b, 27c, 27d, 37a with the width of two pages P1, P2, which can be is guided through the folding device 13 and folded in the center accordingly.

[0056] According to the band turning device 3a, 3b, 3c, 3d of above-mentioned ex...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap